Tuning with the EBL

#3951

Re: Tuning with the EBL

On WOT at 5,400rpm, my GMsec are around 191-192 @ 177 CTS and 114* IAT. Another log at 180* CTS and 134* IAT, the GMsec is showing similar 192-194.

The thermostatic air / hot hair tube from the exhaust manifold is disconnected and the vacuum lines plugged. I'm drawing the majority of my air from the fresh air system that is the hood plumbing.

So that leads me to a question- could the sensor be getting warm and with an elevated temp, throwing things off then? How do I test that?

My IAT is in the air box- off to the side in the snorkel closest to the filters. I could move it- I could put it up by the opening in the hood by the radiator. That's an easy thing to do.

Last edited by CORV3TT3; 05-16-2015 at 07:42 AM.

#3952

Senior Member

iTrader: (5)

Join Date: Sep 2006

Location: Austria

Posts: 951

Likes: 0

Received 2 Likes

on

2 Posts

Car: 84 TA / 89 Formula

Engine: LS1 / L03

Transmission: T56 / 700R4

Axle/Gears: 3.73 / 3.27

Re: Tuning with the EBL

Set the open lop idle flag and see if the oscillation goes away. If not then it isn't a PG issue, more likely a VE table or possibly SA issue.

> after like 5 seconds but the NBO2 just stays at 600-ish mV?

Hard to say why, it may be that the O2 sensor is becoming slower to respond.

RBob.

> after like 5 seconds but the NBO2 just stays at 600-ish mV?

Hard to say why, it may be that the O2 sensor is becoming slower to respond.

RBob.

I also tried getting CL idle more stable and isolate a fueling problem by disabling SA idle compensation and setting boundaries for IAC compensation really wide. It still oscillated, maybe at a tiny bit lower frequency.. not sure how to go on with CL tuning here. Any input here is welcome.

#3953

Re: Tuning with the EBL

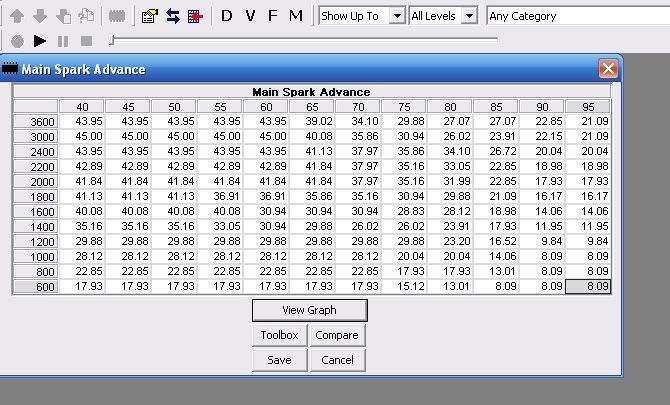

Here's where my VE and SA have landed...

.465"IN / .488"EX cam with the VAFPR at 20psi.

Seems a little wavy between 2k and 2600rpm at KPAs under 60, but overall, pretty smooth. I'm using the PE adder to get to 36 degrees of SA from the '86 Vette SA tables. No knock and and it seems to react very well to all that spark on smog era heads.

Thoughts? Looks okay?

.465"IN / .488"EX cam with the VAFPR at 20psi.

Seems a little wavy between 2k and 2600rpm at KPAs under 60, but overall, pretty smooth. I'm using the PE adder to get to 36 degrees of SA from the '86 Vette SA tables. No knock and and it seems to react very well to all that spark on smog era heads.

Thoughts? Looks okay?

#3954

Re: Tuning with the EBL

Last question... how about the injector compensation? How does that look? I remember reading big injectors are lazy somewhere...

Those tables I believe were for 65lb injectors- but it seems to work okay with the other settings.

I have what should be the 80lb injectors- they are TJ11s- although some sources list them as 90lbs.

* FWIW- My BPC has had some real fudging to get the VE tables under 100 and workable. Max VE is no more than 87 when I have completed learns.

* My duty cycle doesn't get above 85% even when PW is added for other situations (AE, etc).

* The IAC is only 15 steps in park and right around 50-60 in drive.

* IAT is located at the entrance to the fresh air chamber and the thermostatic snorkel is blocked off. I'm pulling all air from the fresh air chamber. The 82 Vettes have a big opening on the top of the airbox that connects with a bellows to the hood and the air chamber.

* Best idle speed seems to be between 750-850rpm in drive. At 750 or less, it seems to want to roll around a little. It is much smoother at around 800ish. Mind you, it does roll about 100 to a max of 130rpms, so the 850 represents the upper end of a roll during idle.

Those tables I believe were for 65lb injectors- but it seems to work okay with the other settings.

I have what should be the 80lb injectors- they are TJ11s- although some sources list them as 90lbs.

* FWIW- My BPC has had some real fudging to get the VE tables under 100 and workable. Max VE is no more than 87 when I have completed learns.

* My duty cycle doesn't get above 85% even when PW is added for other situations (AE, etc).

* The IAC is only 15 steps in park and right around 50-60 in drive.

* IAT is located at the entrance to the fresh air chamber and the thermostatic snorkel is blocked off. I'm pulling all air from the fresh air chamber. The 82 Vettes have a big opening on the top of the airbox that connects with a bellows to the hood and the air chamber.

* Best idle speed seems to be between 750-850rpm in drive. At 750 or less, it seems to want to roll around a little. It is much smoother at around 800ish. Mind you, it does roll about 100 to a max of 130rpms, so the 850 represents the upper end of a roll during idle.

Last edited by CORV3TT3; 05-21-2015 at 09:06 AM.

#3955

Re: Tuning with the EBL

This maybe worthwhile to mention, but the INT and BLM values won't really get above 140 or less than 110 on heavier demand (before they get locked in PE). Moderate to light cruise is usually in the lower 120s and lower 130s, but mostly 2 or 3 in either direction of 128 on either the INT or BLM. For the most part, it seems to hover close to 128 on both pretty good- especially during cruise.

Also- by playing with the CTS multipliers when it has been cold I have a pretty decent match between cAFR and WB readings. I'm pretty close right after the WB gets up to temperature

Is that pretty good then in terms of the tune? Am I missing anything???

Again, the only thing that seems to vex me is getting the VE on the low KPAs right. I have some swing at times between adding a lot of VE and taking it out. I'm usually only +/- 3 in either direction on 55+ KPAs. It's the decel areas that I am chasing at times.

Also- by playing with the CTS multipliers when it has been cold I have a pretty decent match between cAFR and WB readings. I'm pretty close right after the WB gets up to temperature

Is that pretty good then in terms of the tune? Am I missing anything???

Again, the only thing that seems to vex me is getting the VE on the low KPAs right. I have some swing at times between adding a lot of VE and taking it out. I'm usually only +/- 3 in either direction on 55+ KPAs. It's the decel areas that I am chasing at times.

Last edited by CORV3TT3; 05-21-2015 at 09:31 AM.

#3956

Senior Member

Join Date: Jun 2007

Location: Akron, Ohio

Posts: 600

Likes: 0

Received 0 Likes

on

0 Posts

Car: 87 Suburban 2500

Engine: 455 Wildcat ( somewhat modified ))

Transmission: TH400 ( for now )

Axle/Gears: 4.10 ( for now )

Re: Tuning with the EBL

Published vacuum advance range is typically at the distributor, not at the crank ! That means you multiply it times two on an 8 cylinder engine.

Published mechanical advance, I've seen both ways. Crank RPM and dist. RPM.

High speed high vacuum ( relatively closed throttle ) can send the advance to the limits of what the dist can do. It can be upwards of 50 degrees, depending on the static idle advance setting.

A lot of guys look at "race" conditions, mechanical advance with no vacuum.

That's fine on the track, but it sacrifices a good deal of economy during a freeway cruise.

#3957

Re: Tuning with the EBL

Converting from a vacuum advance to a spark table there are some pit-falls to avoid.

Published vacuum advance range is typically at the distributor, not at the crank ! That means you multiply it times two on an 8 cylinder engine.

Published mechanical advance, I've seen both ways. Crank RPM and dist. RPM.

High speed high vacuum ( relatively closed throttle ) can send the advance to the limits of what the dist can do. It can be upwards of 50 degrees, depending on the static idle advance setting.

A lot of guys look at "race" conditions, mechanical advance with no vacuum.

That's fine on the track, but it sacrifices a good deal of economy during a freeway cruise.

Published vacuum advance range is typically at the distributor, not at the crank ! That means you multiply it times two on an 8 cylinder engine.

Published mechanical advance, I've seen both ways. Crank RPM and dist. RPM.

High speed high vacuum ( relatively closed throttle ) can send the advance to the limits of what the dist can do. It can be upwards of 50 degrees, depending on the static idle advance setting.

A lot of guys look at "race" conditions, mechanical advance with no vacuum.

That's fine on the track, but it sacrifices a good deal of economy during a freeway cruise.

#3958

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,982

Received 385 Likes

on

329 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

#3959

Re: Tuning with the EBL

Fast... so... my VE table has a but of a jump in VE at the 100 KPAs area. I also am running 36* of SA per my engine builder in that area, using the PE adder to get to it.

The VE table seems to drop a good deal between 100 and 90 KPAs and then drops less dramatically from the 90 KPAs down.

No knock- seems to run really strong.

Should I be concerned with what the VE table looks like?

#3960

Member

iTrader: (1)

Join Date: Mar 2009

Location: minneapolis

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 GTA Black on Black Hardtop

Engine: 383 miniram/ Ebl

Transmission: 700r4/Performabuilt/3000 Stall

Axle/Gears: 9 bolt / 3.27

Re: Tuning with the EBL

Looking for some advice. I recently picked up a stall issue when going from park to drive. I did a datalog and noticed as soon as I shift into drive my pw goes from around 4.0 to 1.8 then it immediately stalls.

Unsure of why this is happening, any advice is welcome.

Thanks,Tim

Unsure of why this is happening, any advice is welcome.

Thanks,Tim

#3961

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

Is the reduction in PW the cause of the stalling, or is it a symptom of the stalling?

Flyn' blind without a data log of this.

RBob.

Flyn' blind without a data log of this.

RBob.

#3963

Senior Member

iTrader: (5)

Join Date: Sep 2006

Location: Austria

Posts: 951

Likes: 0

Received 2 Likes

on

2 Posts

Car: 84 TA / 89 Formula

Engine: LS1 / L03

Transmission: T56 / 700R4

Axle/Gears: 3.73 / 3.27

Re: Tuning with the EBL

Assuming you're not using an IAT (yet), how would you set up the CTS/IAT threshold? Using a BBC TBI and X-celerator single plane.. Any input welcome, thanks!

#3964

Senior Member

iTrader: (5)

Join Date: Sep 2006

Location: Austria

Posts: 951

Likes: 0

Received 2 Likes

on

2 Posts

Car: 84 TA / 89 Formula

Engine: LS1 / L03

Transmission: T56 / 700R4

Axle/Gears: 3.73 / 3.27

Re: Tuning with the EBL

Ok I got some more questions for the same car (84 vette converted to a BBC TBI from CeaseFireInjection  no IAT yet).

no IAT yet).

Was doing a little VE learn and roughing in the tune a little today. Two issues here, both logs in zip file:

1) The BBC IAC seems to be hanging or something, it's really slow to bring the engine speed back to idle when coasting to a stop or reving. It will hang on at around 1500 for like 10 or 20 seconds and only decay IAC steps very slowly. See attached log (Clemens_Re_00006_endIAChang) towards the end, can be seen nicely here that it hangs but not sure if it's long enough to see the decreasing IAC steps.. Anyone has a cure for that? I have skimmed through the IAC tables a bit but haven't found anything concrete to change yet.

2) I had a very nasty problem towards the end of the tuning session.. EBL would all of a sudden display Inject/Cyl "MPFI, 8" although I'm on a TBI here and even go into SF/single fire! It got into heavy hunting idle loops until I shut it off.. Tried reflashing bin, and ended up pulling ECM connectors since it's in the footwell, which didn't help. Ended up flashing a binary from one or two VE learns before that, which worked. Very strange anyways.. see log with the corresponding name Anyone had something like this happen before?

Anyone had something like this happen before?

no IAT yet).

no IAT yet).Was doing a little VE learn and roughing in the tune a little today. Two issues here, both logs in zip file:

1) The BBC IAC seems to be hanging or something, it's really slow to bring the engine speed back to idle when coasting to a stop or reving. It will hang on at around 1500 for like 10 or 20 seconds and only decay IAC steps very slowly. See attached log (Clemens_Re_00006_endIAChang) towards the end, can be seen nicely here that it hangs but not sure if it's long enough to see the decreasing IAC steps.. Anyone has a cure for that? I have skimmed through the IAC tables a bit but haven't found anything concrete to change yet.

2) I had a very nasty problem towards the end of the tuning session.. EBL would all of a sudden display Inject/Cyl "MPFI, 8" although I'm on a TBI here and even go into SF/single fire! It got into heavy hunting idle loops until I shut it off.. Tried reflashing bin, and ended up pulling ECM connectors since it's in the footwell, which didn't help. Ended up flashing a binary from one or two VE learns before that, which worked. Very strange anyways.. see log with the corresponding name

Anyone had something like this happen before?

Anyone had something like this happen before?

#3965

Senior Member

iTrader: (5)

Join Date: Sep 2006

Location: Austria

Posts: 951

Likes: 0

Received 2 Likes

on

2 Posts

Car: 84 TA / 89 Formula

Engine: LS1 / L03

Transmission: T56 / 700R4

Axle/Gears: 3.73 / 3.27

Re: Tuning with the EBL

Ok so somehow I mixed up binaries and I was indeed using an MPFI binary.. Guess that clears up my questions of the last post

Something went wrong when updating bins in the Flash banks I think, still had the bins of the previous update flash in the folder..

This is what Rbob recommended concerning my "no IAT"-question:

Clear (un-check) this flag:

Malf Flags - 12 thru 24 - Bit 1 - IAT23

Set this table to all 100%:

IAT/CTS - Blend Filter

..as simple as that ^^

Something went wrong when updating bins in the Flash banks I think, still had the bins of the previous update flash in the folder..

This is what Rbob recommended concerning my "no IAT"-question:

Clear (un-check) this flag:

Malf Flags - 12 thru 24 - Bit 1 - IAT23

Set this table to all 100%:

IAT/CTS - Blend Filter

..as simple as that ^^

#3966

Re: Tuning with the EBL

I've NEVER been happy with how that thing looked- and I think there were some unintended consequences too. It idled great in open loop- but closed loop was a bit noticeable... and slightly rough.

I've also been running the TJ11 injectors with the same pulse width as the 65lb-ers. To do that, I had one heck of a fudged BPC table (97-151) on 20lbs of pressure.

Well, I decided to use the EBL Utility tool and to go back and revise the BPC and then to grab a set of offsets for a known 80lb injector set up... the 3001 BIN... remembering things I had read about slow response and larger injectors.

That fixed the look of the VE table and I think the VE learns are more consistent at the lower KPAs. 90 & 100 KPAs don't look screwey anymore and neither do the lower columns.

I also adjusted the O2 window and brought the values up by 50mvs. That helped the closed loop idle out a lot. And- the low BLMs at idle (sub 120) I was seeing are gone.

I also was able to experiment with the BPC filter and to try to fine tune throttle response with the VAFPR. 37% was the original setting... 47% was a bit jumpy as it transitioned off idle. 42% seems to be a good midpoint with good reaction.

I've also been running the TJ11 injectors with the same pulse width as the 65lb-ers. To do that, I had one heck of a fudged BPC table (97-151) on 20lbs of pressure.

Well, I decided to use the EBL Utility tool and to go back and revise the BPC and then to grab a set of offsets for a known 80lb injector set up... the 3001 BIN... remembering things I had read about slow response and larger injectors.

That fixed the look of the VE table and I think the VE learns are more consistent at the lower KPAs. 90 & 100 KPAs don't look screwey anymore and neither do the lower columns.

I also adjusted the O2 window and brought the values up by 50mvs. That helped the closed loop idle out a lot. And- the low BLMs at idle (sub 120) I was seeing are gone.

I also was able to experiment with the BPC filter and to try to fine tune throttle response with the VAFPR. 37% was the original setting... 47% was a bit jumpy as it transitioned off idle. 42% seems to be a good midpoint with good reaction.

Last edited by CORV3TT3; 06-07-2015 at 04:34 PM.

#3967

Re: Tuning with the EBL

This thread is awesome, but its soo big, I can't find what I am looking for.

For Spark Advance, is the value that I set in the SA-MAIN table going to be what the computer shoots for, or does it ADD the BASE/INITAL Spark to it? So if a given cell has 36, and my base timing is 6 degrees.,will I end up with 42 degrees of total timing, or will the computer add 30 to the 6 base to end up at 36?

For Spark Advance, is the value that I set in the SA-MAIN table going to be what the computer shoots for, or does it ADD the BASE/INITAL Spark to it? So if a given cell has 36, and my base timing is 6 degrees.,will I end up with 42 degrees of total timing, or will the computer add 30 to the 6 base to end up at 36?

#3968

Senior Member

Join Date: Oct 2001

Location: RI

Posts: 708

Likes: 0

Received 0 Likes

on

0 Posts

Car: 93 Caprice 9C1

Engine: L05

Transmission: 4L60

Axle/Gears: 3.42

Re: Tuning with the EBL

Short answer: it subtracts. So if you have commanded 36, and the computer knows you already have 6 base, it will add 30.

To use your example, if your main table has a cell with 36 and your base timing is 6, and you DIDN'T enter this in the base timing scaler, then it would add. If you DID enter this in the base timing scaler, it would subtract whatever that is. Lesson: always tell the computer the truth (if you have 6° BTDC, then account for that in the tune).

I suppose if you had retard as your base timing (and told the computer that), then it would add. But most people probably don't have that.

To use your example, if your main table has a cell with 36 and your base timing is 6, and you DIDN'T enter this in the base timing scaler, then it would add. If you DID enter this in the base timing scaler, it would subtract whatever that is. Lesson: always tell the computer the truth (if you have 6° BTDC, then account for that in the tune).

I suppose if you had retard as your base timing (and told the computer that), then it would add. But most people probably don't have that.

Last edited by kevm14; 07-31-2015 at 09:31 AM.

#3969

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

#3971

Re: Tuning with the EBL

I think I've been making good progress so far.

I think I've kinda figured out how much of a difference the intake design (cross ram), airbox (factory with the snorkel/thermostatic air inlet blocked off), and intake plumbing (fresh air passage in the hood) makes for my car.

I had scoured a lot of threads here about CTS/IAT- and they helped me understand the dynamics a lot better. I think notes and then trial and error allowed me to walk things in.

For months, I seem to have had VE learns that would add fuel in the morning and subtract it in the afternoon- as well as add fuel and take it away as the oil temp warmed up or the CTS was lower than 185. Seems at around 180-ish degrees, I have a pivot point for when the engine is fully warm. That's when the oil is warmed up, the water temp is warmed up, and the intake is fully warmed up. Days with 68* mornings and 95* afternoons was playing havoc with my VE learns- as was the oil temp. The VE learns and TunerPro's compare was a great combination to use as a guide to start walking things in... like when a bit lean in the AM and not fully warm, add a couple % here or there on CTS/IAT bias and CTS AFR multipliers until it matches the afternoon and no significant fuel was being added or subtracted. I started to see consistency where I needed it.

So, I'm seeing a lot greater consistency during open loop too in terms of AFRs tracking closer to cAFRs.

Now, I'm pretty much within +/- 1-3 on my VE learns from 176* and not fully warmed up through 188* with everything fully warmed up.

My INT/BLM is by far and away the most consistent I have ever had them- and my VE table looks pretty good without a lot of massive spikes. Now, I did have to hide some fuel in the 90 KPAs @ 4,400rpm to compensate for a lean condition during the 1-2 shift, but otherwise the fueling seems pretty good now.

I think I have my INT settings pretty much where it'll roll between 14.2 and 15.0 at the extremes but hover pretty close to 14.7 most of the time. Tweaking the settings for INT O2 mVs made a huge difference in terms of coming in/out of closed loop as well as the transition from stopped at a light in drive to rolling forward. Also have the proportional gains in a pretty good place where its pretty seamless coming into and out of closed loop.

I am still a little rich at the lower KPAs (45 and lower) at some points- but that's okay I guess. It's only in deceleration that the cAFR would be 15s and I'd actually be in the 13s.

QUESTION... I've never seen DFCO kick in (I do see DE, just not DFCO). Is that something that makes a big difference and I should be concerned that I haven't seen it blip before?

I think I've kinda figured out how much of a difference the intake design (cross ram), airbox (factory with the snorkel/thermostatic air inlet blocked off), and intake plumbing (fresh air passage in the hood) makes for my car.

I had scoured a lot of threads here about CTS/IAT- and they helped me understand the dynamics a lot better. I think notes and then trial and error allowed me to walk things in.

For months, I seem to have had VE learns that would add fuel in the morning and subtract it in the afternoon- as well as add fuel and take it away as the oil temp warmed up or the CTS was lower than 185. Seems at around 180-ish degrees, I have a pivot point for when the engine is fully warm. That's when the oil is warmed up, the water temp is warmed up, and the intake is fully warmed up. Days with 68* mornings and 95* afternoons was playing havoc with my VE learns- as was the oil temp. The VE learns and TunerPro's compare was a great combination to use as a guide to start walking things in... like when a bit lean in the AM and not fully warm, add a couple % here or there on CTS/IAT bias and CTS AFR multipliers until it matches the afternoon and no significant fuel was being added or subtracted. I started to see consistency where I needed it.

So, I'm seeing a lot greater consistency during open loop too in terms of AFRs tracking closer to cAFRs.

Now, I'm pretty much within +/- 1-3 on my VE learns from 176* and not fully warmed up through 188* with everything fully warmed up.

My INT/BLM is by far and away the most consistent I have ever had them- and my VE table looks pretty good without a lot of massive spikes. Now, I did have to hide some fuel in the 90 KPAs @ 4,400rpm to compensate for a lean condition during the 1-2 shift, but otherwise the fueling seems pretty good now.

I think I have my INT settings pretty much where it'll roll between 14.2 and 15.0 at the extremes but hover pretty close to 14.7 most of the time. Tweaking the settings for INT O2 mVs made a huge difference in terms of coming in/out of closed loop as well as the transition from stopped at a light in drive to rolling forward. Also have the proportional gains in a pretty good place where its pretty seamless coming into and out of closed loop.

I am still a little rich at the lower KPAs (45 and lower) at some points- but that's okay I guess. It's only in deceleration that the cAFR would be 15s and I'd actually be in the 13s.

QUESTION... I've never seen DFCO kick in (I do see DE, just not DFCO). Is that something that makes a big difference and I should be concerned that I haven't seen it blip before?

Last edited by CORV3TT3; 08-05-2015 at 09:43 PM.

#3972

Re: Tuning with the EBL

I've seen earlier in this thread that EBL should learn WOT from the WB input.

Mine learns fine when MAP < 70. However I rarely see a learn when MAP > 70. Is there a secret to getting more learns in this area?

Mine learns fine when MAP < 70. However I rarely see a learn when MAP > 70. Is there a secret to getting more learns in this area?

#3973

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

I agree.

Was it possibly disabled via the CTS term? Check the other terms such as the RPM & MPH that need to be exceeded for DFCO to become active. Don't lower them too much otherwise you can have stalling issues.

DFCO is there is protect the cat-con during decel. The density of the mix in the chambers is low and hard to light-off. Misfiring can occur without the driver even feeling it. That will overheat and kill a cat-con in no time.

I disabled it on a stick shift car as when the ECM exited DFCO is was rough. Others have done the same.

RBob.

QUESTION... I've never seen DFCO kick in (I do see DE, just not DFCO). Is that something that makes a big difference and I should be concerned that I haven't seen it blip before?

DFCO is there is protect the cat-con during decel. The density of the mix in the chambers is low and hard to light-off. Misfiring can occur without the driver even feeling it. That will overheat and kill a cat-con in no time.

I disabled it on a stick shift car as when the ECM exited DFCO is was rough. Others have done the same.

RBob.

#3974

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

To use the WB VE Learn mode set the closed loop CTS threshold high to keep the ECM in open loop.

RBob.

#3975

Re: Tuning with the EBL

Closed loop is disabled with the CTS set to something like 151C.

Yes, I do see PE during WOT during the data logging.

#3976

Re: Tuning with the EBL

Was it possibly disabled via the CTS term? Check the other terms such as the RPM & MPH that need to be exceeded for DFCO to become active. Don't lower them too much otherwise you can have stalling issues.

DFCO is there is protect the cat-con during decel. The density of the mix in the chambers is low and hard to light-off. Misfiring can occur without the driver even feeling it. That will overheat and kill a cat-con in no time.

I disabled it on a stick shift car as when the ECM exited DFCO is was rough. Others have done the same.

RBob.

DFCO is there is protect the cat-con during decel. The density of the mix in the chambers is low and hard to light-off. Misfiring can occur without the driver even feeling it. That will overheat and kill a cat-con in no time.

I disabled it on a stick shift car as when the ECM exited DFCO is was rough. Others have done the same.

RBob.

Yeah... I was thinking something might have been switched so I went through all the settings I could find for TB3 & DFCO and compared them.

So, I haven't deviated from the setting for TB3- which was the BIN I started with (albeit HEAVILY tweaked now).

Eh... no stalling issues and no problems related to DFCO- so I guess I'll leave things alone before I fix it and make it worse somehow.

#3977

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

Pulls in higher gears such as 3rd are better.

RBob.

#3978

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

Okay guys thank you all for the help as always. I also apologize for what my last thread turned into, it was not my intention at all.

Recap 357ci TPI with 60lb injectors and EBL, was having a hard time tuning idle with the 60lb injectors which were sized for boost and to try and prevent the need for a secondary fuel pump. Recently the car died, no spark and the ICM was the culprit. This was swapped out and of course the old file didn’t run well so the ICM was affecting the tuneablility of the car. I roughed in the VE to get a somewhat stable idle then converted over to E85. I changed the fuel injector size in the EBL by decreasing it by 30% for the E85. Ran half e85 doing VE learns until it went empty and put in a few gallons of E85 so I didn’t just dump in a ton of ETOH and pray for it to start.

So my current issue with the idle in OL. The surging of the lean rich at idle seems to get worse with the WB VE learns… the VE table gets really steep which I thought may be the result of the actual VE wanting to be at the average of the two points so I went to town on the VE table making look how I “thought it should” and ironically It idles though not well. I could use some help figuring out where to add and remove fuel from the VE table at idle. The data file is from a cold start to operating temp and I included the bin file from that run.

Recap 357ci TPI with 60lb injectors and EBL, was having a hard time tuning idle with the 60lb injectors which were sized for boost and to try and prevent the need for a secondary fuel pump. Recently the car died, no spark and the ICM was the culprit. This was swapped out and of course the old file didn’t run well so the ICM was affecting the tuneablility of the car. I roughed in the VE to get a somewhat stable idle then converted over to E85. I changed the fuel injector size in the EBL by decreasing it by 30% for the E85. Ran half e85 doing VE learns until it went empty and put in a few gallons of E85 so I didn’t just dump in a ton of ETOH and pray for it to start.

So my current issue with the idle in OL. The surging of the lean rich at idle seems to get worse with the WB VE learns… the VE table gets really steep which I thought may be the result of the actual VE wanting to be at the average of the two points so I went to town on the VE table making look how I “thought it should” and ironically It idles though not well. I could use some help figuring out where to add and remove fuel from the VE table at idle. The data file is from a cold start to operating temp and I included the bin file from that run.

#3979

Re: Tuning with the EBL

Originally Posted by bphage

Recap 357ci TPI with 60lb injectors and EBL, was having a hard time tuning idle with the 60lb injectors which were sized for boost and to try and prevent the need for a secondary fuel pump. Recently the car died, no spark and the ICM was the culprit. This was swapped out and of course the old file didn’t run well so the ICM was affecting the tuneablility of the car. I roughed in the VE to get a somewhat stable idle then converted over to E85. I changed the fuel injector size in the EBL by decreasing it by 30% for the E85. Ran half e85 doing VE learns until it went empty and put in a few gallons of E85 so I didn’t just dump in a ton of ETOH and pray for it to start.

So my current issue with the idle in OL. The surging of the lean rich at idle seems to get worse with the WB VE learns… the VE table gets really steep which I thought may be the result of the actual VE wanting to be at the average of the two points so I went to town on the VE table making look how I “thought it should” and ironically It idles though not well. I could use some help figuring out where to add and remove fuel from the VE table at idle. The data file is from a cold start to operating temp and I included the bin file from that run.

So my current issue with the idle in OL. The surging of the lean rich at idle seems to get worse with the WB VE learns… the VE table gets really steep which I thought may be the result of the actual VE wanting to be at the average of the two points so I went to town on the VE table making look how I “thought it should” and ironically It idles though not well. I could use some help figuring out where to add and remove fuel from the VE table at idle. The data file is from a cold start to operating temp and I included the bin file from that run.

Edit: Also remember, when you need to calculate your injector needs when running E85, the formula is Injector Size X 1.47. So in your case, you initially went with 60-lb injectors so we can assume your safe at 80% Duty Cycle with these running gasoline. Running E85 you would then need approximately 90-lb injectors to meet the same needs with the new fuel type...

Last edited by Street Lethal; 08-09-2015 at 04:15 PM.

#3980

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

What exactly did you do, you maintained your 60-lb injectors, but decreased their size in your bin to compensate for E85? E85 has a stoichiometric value of 9.86 as opposed to the 14.7 gasoline (14.2 w/added ethanol) value. Thirty percent of 14.7 is 4.4, which will give you a 10.3 mixture running gasoline, and a 9.79 value running gasoline with w/added the ethanol, so you're close in terms of that, but you did it backward. Your bin still reflects the higher numeric values in terms of air/fuel in your Open Loop - AFR vs RPM & VAC table, as well as in your Closed Loop table. Think about it for a second, let's say you pulled the 60-lb injectors and installed 30% less which is 42-lb injectors, rather than changing it in the bin (which is essentially the same thing) to compensate for a lower stoichiometric value, but you kept the target air/fuel in the bin the same. All you did was make it harder for the ECM because your fuel flow is off by 30%. Bring your injectors back to their normal 60-lb setting, then go into your Open Loop tables and change the targeted stoich values from 14.0 to 9.86, as this is the number that the EBL Learn will utilize...

Edit: Also remember, when you need to calculate your injector needs when running E85, the formula is Injector Size X 1.47. So in your case, you initially went with 60-lb injectors so we can assume your safe at 80% Duty Cycle with these running gasoline. Running E85 you would then need approximately 90-lb injectors to meet the same needs with the new fuel type...

Edit: Also remember, when you need to calculate your injector needs when running E85, the formula is Injector Size X 1.47. So in your case, you initially went with 60-lb injectors so we can assume your safe at 80% Duty Cycle with these running gasoline. Running E85 you would then need approximately 90-lb injectors to meet the same needs with the new fuel type...

If I am going to need the extra fuel pump to support extra pressure from the injectors being on the small side then I figure I would give it a go with E85 as then I don't have to worry about a meth kit later. There are enough 85 stations in the bay area to get me to the trac and beach etc

Last edited by bphage; 08-09-2015 at 04:34 PM.

#3981

Re: Tuning with the EBL

Originally Posted by bphage

I changed the injector size originally thinking I could just leave the stoich the same because though it reads 14.7 it really is at 9.86.

#3982

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

No no, remember, the O2 is telling the ECM when it see's whatever it is programmed for in terms of stoich. Although in theory what you did sounds right to you, remember that the ECM will keep correcting until it see's 14.7, regardless what you did. If it is set for 14.7, then that is what it will correct to, and it will keep correcting until it obtains that value. Changing the injector fuel flow by 30% only made it all the more difficult for the ECM. All you need to do when running E85 is target a new stoich, and just have enough injector to maintain 80% DC...

Thanks!

Edit: Thanks, was able to log into the tt-1 changed the stoic value to 9.77 and 0 volts to AFR =5 and 5 volts to AFR = 15, went back to the last good tune on gas then changed the injector size to 61lb to account for the FPR set to 45psi, and set the stoich closed loop value to 9.80. I will start again!

Last edited by bphage; 08-09-2015 at 08:11 PM.

#3983

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

okay, so how do you change the ebl to see the WB from tt-1 0v = 10 to 5v =20 to the 0v = 5 and 5v = 15?; I don't see a way to change it in the adc channel drop down? As is I would be targeting an AFR less than 10 which would always be 0 volts???

Thanks

Thanks

#3984

Re: Tuning with the EBL

To change stoich on the TT1, you would use the utility program. There is a box that says AFR on the lower left hand side of the screen.

#3985

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

#3986

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

A WB controller needs to know what the stoich AFR is. It always knows what lambda is, the reported AFR is a calculation from lambda.

Our TT-1 WB controller setup utility has an entry for the stoich AFR. As the controller needs to know this for the fuel that is being used.

There are many ways to go with this. Even running E85 one can use gasoline AFRs. And tweak the extra 30% more fuel via the BPC or fuel injector constant. Otherwise the VE table will max out trying to add the additional fuel.

Or, change the TT-1 WB set up for the proper E85 AFR, and change the EBL ECM AFR tables to E85 values. Same as above, it all drops into place.

All depends upon what stoich AFR you want to look at...

RBob.

Our TT-1 WB controller setup utility has an entry for the stoich AFR. As the controller needs to know this for the fuel that is being used.

There are many ways to go with this. Even running E85 one can use gasoline AFRs. And tweak the extra 30% more fuel via the BPC or fuel injector constant. Otherwise the VE table will max out trying to add the additional fuel.

Or, change the TT-1 WB set up for the proper E85 AFR, and change the EBL ECM AFR tables to E85 values. Same as above, it all drops into place.

All depends upon what stoich AFR you want to look at...

RBob.

You can change the stoich AFR to 14.2, note that you will need to either lower the VE tables or the BPC vs VAC to compensate. Otherwise the BLM will drop to do so. If you do make this change there are some other tables that should also be changed.

Such as the crank, PE, highway, and open loop AFR tables.

Then if you are using a WB for VE Learns, it too needs to be set up for the different stoich AFR.

RBob.

Such as the crank, PE, highway, and open loop AFR tables.

Then if you are using a WB for VE Learns, it too needs to be set up for the different stoich AFR.

RBob.

All that is needed is to change these entries--

• Closed Loop - Stoich AFR

• Closed Loop - Idle Lean Limit

• Closed Loop - Max Lean AFR

• PE AFR Commanded table

• Open Loop AFR vs RPM vs VAC

• Hwy AFR vs MAP

• Open Loop - AFR Multiplier vs CTS

SR-71

• Closed Loop - Stoich AFR

• Closed Loop - Idle Lean Limit

• Closed Loop - Max Lean AFR

• PE AFR Commanded table

• Open Loop AFR vs RPM vs VAC

• Hwy AFR vs MAP

• Open Loop - AFR Multiplier vs CTS

SR-71

Searching for E85 I found the above posts…I had thought I remembered just changing the injector constant which looks like Rbob was touching upon above…. But let’s not be lazy and get it right so I can fix the VE table. If I follow Rbob correctly we need to change the “EBL ECM AFR Tables” which seem to include the Crank, PE, highway, and open loop AFR tables. Not sure what exactly needs to be done to them and if any of the other table need to be changed… I could find the following tables that may be adjusted:

The tables I believe Rbob was referencing:

1. Crank – AFR – Not sure what to do here? Needs to be less…? ~30%?

2. PE – AFR Commanded – changed all from 12.8 to max power rich of 7

3. HiWay – AFR – Change all values to 10.0 except at 90 and 100, I set those to 9.5 (For references original table read from map of 20 – 100: 15, 15, 16.2, 16.6, 16.4, 15.8, 15, 14.4, 14.4) I could probably go leaner though looks like some people run as lean as 12:1 but not sure I want to risk that.

4. Open loop – AFR vs RPM & Vac – I do not understand the shape of this table, I basically continued the same shape by highlighting the whole table and dragging the 14.7 values down to 9.8 then I changed 70/2000 – 70/6375 to 10 as 10.4 seems a little lean. Is there any reason I can’t just change them all to stoich?

Other tables I think need to be changed but not sure:

5. Closed loop- stoich AFR – Changed from 14.7 to 9.80

6. Open Loop –AFR Multiplier vs CTS – Did not change

7. Choke – AFR – Did not change

Did not change the following and don’t think they need to be changed:

8. Open loop – max lean AFR – Did not change from 16.5 - thinking about changing to 11

9. PE – Cold AFR Richer – Did not change from 1.6

10. PE – AFR Attack enrich over time – Did not change from 6.27

11. PE – AFR decay Enrich over time – Did not change from 18.82

12. PE – AFR enrich over time – Did not change from 1 max dAFR

13. HotRST – AFR enrichment – Did not change from 1.50

14. Open loop – idle lean limit – Did not change from 13.5 - thinking about changing to 10.5

I cant find these tables from SR-71:

15. Closed Loop - Idle Lean Limit

16. Closed Loop - Max Lean AFR

Last edited by bphage; 08-10-2015 at 01:51 AM.

#3987

Re: Tuning with the EBL

I think my biggest challenge right now is getting the volume of incoming air measured right within a specific time period and set of conditions.

Everything else seems to be pretty good. Getting the O2 windows and the INT Lean, Median, and Rich points down has helped a lot in terms of getting the baseline for where the AFR should land.

My AFRs seem to line up decently when in open loop before it hits the CL/CTS threshold.

During closed loop, it is not uncommon for me to see a BLM around 135-140 in the time period when the CTS is between 175 and 185 and the oil temp hasn't reached its warm state. That said, my VE learn % will roll around +5-7% when the oil isn't up to temp and then within +/- 1-3 in either direction once fully warm. I believe the VE learns are telling me I need a bit more fuel there. Which means my air mass is being read as smaller than it is.

I think that is the result of the intake remaining cool until the block is thoroughly warm. My assumption is the air density calculation isn't fully correct. My guess is that with a crossram intake, its very sensitive to the temp. I won't get the insulation benefit of an air gap.

So, I get heat soak if the IAT is mounted in the air box (metal and right above the intake) and heat soak if it is mounted at the opening for the fresh air chamber (air passage running from the radiator to the air box). I have it mounted just behind the grill where the headlight actuators are. Don't get me wrong- the integrator does a good job of controlling things- it's usually pretty close (less than a 10% difference when it's between cold and warm). I'm just trying to refine that time period between "cool" and "fully warm"

I've been tweaking the Open Loop - AFR Multiplier vs CTS to front load it with fuel right up until when the oil is up to temperature. That has brought OL AFRs into range according to the WB. The oil won't get up to temp until the engine is at least 178* or so and has been run around a little- warming up the car in the driveway won't get it fully warm. As I stated in a previous post, it seems that 180* CTS is the pivot point for the oil temp and then the intake. That is highlighted in the picture below.

I've balanced the IAT/CTS Blend Filter towards the CTS at the low GmSecs that line up with idle. At idle, it seems the air mass is prone to picking up heat as it comes over the radiator and into the fresh air chamber (highlighted). I've also pushed the bias towards the IAT at the higher GmSecs as the air moves faster it doesn't pick up as much heat from the radiator, engine, and the hood (also highlighted).

Any thoughts? Does it sound like I am on the right track?

Everything else seems to be pretty good. Getting the O2 windows and the INT Lean, Median, and Rich points down has helped a lot in terms of getting the baseline for where the AFR should land.

My AFRs seem to line up decently when in open loop before it hits the CL/CTS threshold.

During closed loop, it is not uncommon for me to see a BLM around 135-140 in the time period when the CTS is between 175 and 185 and the oil temp hasn't reached its warm state. That said, my VE learn % will roll around +5-7% when the oil isn't up to temp and then within +/- 1-3 in either direction once fully warm. I believe the VE learns are telling me I need a bit more fuel there. Which means my air mass is being read as smaller than it is.

I think that is the result of the intake remaining cool until the block is thoroughly warm. My assumption is the air density calculation isn't fully correct. My guess is that with a crossram intake, its very sensitive to the temp. I won't get the insulation benefit of an air gap.

So, I get heat soak if the IAT is mounted in the air box (metal and right above the intake) and heat soak if it is mounted at the opening for the fresh air chamber (air passage running from the radiator to the air box). I have it mounted just behind the grill where the headlight actuators are. Don't get me wrong- the integrator does a good job of controlling things- it's usually pretty close (less than a 10% difference when it's between cold and warm). I'm just trying to refine that time period between "cool" and "fully warm"

I've been tweaking the Open Loop - AFR Multiplier vs CTS to front load it with fuel right up until when the oil is up to temperature. That has brought OL AFRs into range according to the WB. The oil won't get up to temp until the engine is at least 178* or so and has been run around a little- warming up the car in the driveway won't get it fully warm. As I stated in a previous post, it seems that 180* CTS is the pivot point for the oil temp and then the intake. That is highlighted in the picture below.

I've balanced the IAT/CTS Blend Filter towards the CTS at the low GmSecs that line up with idle. At idle, it seems the air mass is prone to picking up heat as it comes over the radiator and into the fresh air chamber (highlighted). I've also pushed the bias towards the IAT at the higher GmSecs as the air moves faster it doesn't pick up as much heat from the radiator, engine, and the hood (also highlighted).

Any thoughts? Does it sound like I am on the right track?

Last edited by CORV3TT3; 08-10-2015 at 08:06 AM.

#3988

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

Open Loop - Idle Lean Limit

Open Loop - Max Lean AFR

I've attached the SS SR-71 put together for converting to E85. Paste your tables & parameters into the first tab, the second tab has the new values to copy & paste into your BIN.

Note that he missed the Crank - AFR table, so multiply that whole table by the "AFR Adjustment" value found on the first tab of the SS.

As for the injectors, as these the Siemens Deka long 60's? Also referred to as Mototrons. If so let me know the fuel pressure and I'll calc the injector compensation values and post them.

That will make getting your engine to idle properly much easier.

RBob.

#3989

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

My AFRs seem to line up decently when in open loop before it hits the CL/CTS threshold.

During closed loop, it is not uncommon for me to see a BLM around 135-140 in the time period when the CTS is between 175 and 185 and the oil temp hasn't reached its warm state. That said, my VE learn % will roll around +5-7% when the oil isn't up to temp and then within +/- 1-3 in either direction once fully warm. I believe the VE learns are telling me I need a bit more fuel there. Which means my air mass is being read as smaller than it is.

Any thoughts? Does it sound like I am on the right track?

During closed loop, it is not uncommon for me to see a BLM around 135-140 in the time period when the CTS is between 175 and 185 and the oil temp hasn't reached its warm state. That said, my VE learn % will roll around +5-7% when the oil isn't up to temp and then within +/- 1-3 in either direction once fully warm. I believe the VE learns are telling me I need a bit more fuel there. Which means my air mass is being read as smaller than it is.

Any thoughts? Does it sound like I am on the right track?

If the engine doesn't like it then tweaking the CTS/IAT blend can be helpful.

RBob.

#3990

Re: Tuning with the EBL

Thanks RBob!

So I left the VE table alone and added a smidge more of offset to the IAT side of the table because it was running a bit lean once it was at the oil's operating temperature.

I landed at -1s and -2s pretty much across the VE table (outside of idle rpms) as it was 3/4s warmed up through full operating temp for the oil. I had some 0s- and then a couple of 1s too. But it was uniform in terms of staying at those values through full oil warm-up.

I copied the new values for VE and flashed it over.

I'm going to keep track of it from here out and like you've said... take notes and adjust over seasons as needed.

I think I'm pretty much there!

So I left the VE table alone and added a smidge more of offset to the IAT side of the table because it was running a bit lean once it was at the oil's operating temperature.

I landed at -1s and -2s pretty much across the VE table (outside of idle rpms) as it was 3/4s warmed up through full operating temp for the oil. I had some 0s- and then a couple of 1s too. But it was uniform in terms of staying at those values through full oil warm-up.

I copied the new values for VE and flashed it over.

I'm going to keep track of it from here out and like you've said... take notes and adjust over seasons as needed.

I think I'm pretty much there!

Last edited by CORV3TT3; 08-10-2015 at 04:59 PM.

#3991

Commanded vs Actual Timing

Tonight I checked my timing with one of those DIAL timing lights so I could see what I was getting at the flywheel.

At 3000rpm/35kpa the table was set at 46 degrees. The WUD display also read out 46 degrees. However with the timing light only was at 32 degrees when I got the timing mark to line up to zero.

I rechecked my base timing by disconnecting the ESC wire and I do have a few degrees of difference between the actual timing with the light and what was entered into TunerPro as the base timing. (4 degrees). I guess last time I set the timing maybe the car wasn't warmed up enough.

What would cause the commanded timing to be so far off from what I am seeing with the light?

At 3000rpm/35kpa the table was set at 46 degrees. The WUD display also read out 46 degrees. However with the timing light only was at 32 degrees when I got the timing mark to line up to zero.

I rechecked my base timing by disconnecting the ESC wire and I do have a few degrees of difference between the actual timing with the light and what was entered into TunerPro as the base timing. (4 degrees). I guess last time I set the timing maybe the car wasn't warmed up enough.

What would cause the commanded timing to be so far off from what I am seeing with the light?

#3992

TCC

Well.....here is a good one. I bet this hasn't come up before.

Part 1:

I have a manual transmission. I have Option Word 2, bit 7 -TCC UNCHECKED. However in the WUD the TCC light is always turning on and off. I've even seen it on at idle. (Can't imagine the torque converter would ever lock up then)

Part 2:

Whenever the TCC light comes on in WUD my SHIFT LIGHT on the dash also comes on. Wire A3 is connected to the shift light. I've had the Shift Light Output set to 0 and also tried 10, but it didn't make any difference.

Suggestions?

Part 1:

I have a manual transmission. I have Option Word 2, bit 7 -TCC UNCHECKED. However in the WUD the TCC light is always turning on and off. I've even seen it on at idle. (Can't imagine the torque converter would ever lock up then)

Part 2:

Whenever the TCC light comes on in WUD my SHIFT LIGHT on the dash also comes on. Wire A3 is connected to the shift light. I've had the Shift Light Output set to 0 and also tried 10, but it didn't make any difference.

Suggestions?

#3993

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Commanded vs Actual Timing

Tonight I checked my timing with one of those DIAL timing lights so I could see what I was getting at the flywheel.

At 3000rpm/35kpa the table was set at 46 degrees. The WUD display also read out 46 degrees. However with the timing light only was at 32 degrees when I got the timing mark to line up to zero.

I rechecked my base timing by disconnecting the ESC wire and I do have a few degrees of difference between the actual timing with the light and what was entered into TunerPro as the base timing. (4 degrees). I guess last time I set the timing maybe the car wasn't warmed up enough.

What would cause the commanded timing to be so far off from what I am seeing with the light?

At 3000rpm/35kpa the table was set at 46 degrees. The WUD display also read out 46 degrees. However with the timing light only was at 32 degrees when I got the timing mark to line up to zero.

I rechecked my base timing by disconnecting the ESC wire and I do have a few degrees of difference between the actual timing with the light and what was entered into TunerPro as the base timing. (4 degrees). I guess last time I set the timing maybe the car wasn't warmed up enough.

What would cause the commanded timing to be so far off from what I am seeing with the light?

It is best to set the base timing with the engine fully warmed up.

Last is the ICM latency, this can cause the timing to be off by quite a bit. See this thread:

https://www.thirdgen.org/forums/diy-...ncy-table.html

RBob.

#3994

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: TCC

Well.....here is a good one. I bet this hasn't come up before.

Part 1:

I have a manual transmission. I have Option Word 2, bit 7 -TCC UNCHECKED. However in the WUD the TCC light is always turning on and off. I've even seen it on at idle. (Can't imagine the torque converter would ever lock up then)

Part 2:

Whenever the TCC light comes on in WUD my SHIFT LIGHT on the dash also comes on. Wire A3 is connected to the shift light. I've had the Shift Light Output set to 0 and also tried 10, but it didn't make any difference.

Suggestions?

Part 1:

I have a manual transmission. I have Option Word 2, bit 7 -TCC UNCHECKED. However in the WUD the TCC light is always turning on and off. I've even seen it on at idle. (Can't imagine the torque converter would ever lock up then)

Part 2:

Whenever the TCC light comes on in WUD my SHIFT LIGHT on the dash also comes on. Wire A3 is connected to the shift light. I've had the Shift Light Output set to 0 and also tried 10, but it didn't make any difference.

Suggestions?

Yepper's, it is the reverse lockout feature using the TCC status bit & output.

To disable it set this parameter to zero:

Stick - Reverse Lock Out MPH

It is right after the TCC parameters under scalars.

Part 2:

Be sure to un-check the CCP option flag:

Option Word 5 - Bit 7 - CCP

And don't go by the stock dash tach, check the shift light active via the WUD for RPM.

RBob.

#3995

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: TCC

To use A3 the Shift Light Output is set to 0 or 10. This uses the CCP output.

To switch the shift light output to pin A7, set the parameter to 8.

There is a chart in the Calibration Help file for this.

RBob.

#3996

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

Those aren't closed loop parameters. Dave just typo'd them, see these:

Open Loop - Idle Lean Limit

Open Loop - Max Lean AFR

I've attached the SS SR-71 put together for converting to E85. Paste your tables & parameters into the first tab, the second tab has the new values to copy & paste into your BIN.

Note that he missed the Crank - AFR table, so multiply that whole table by the "AFR Adjustment" value found on the first tab of the SS.

As for the injectors, as these the Siemens Deka long 60's? Also referred to as Mototrons. If so let me know the fuel pressure and I'll calc the injector compensation values and post them.

That will make getting your engine to idle properly much easier.

RBob.

Open Loop - Idle Lean Limit

Open Loop - Max Lean AFR

I've attached the SS SR-71 put together for converting to E85. Paste your tables & parameters into the first tab, the second tab has the new values to copy & paste into your BIN.

Note that he missed the Crank - AFR table, so multiply that whole table by the "AFR Adjustment" value found on the first tab of the SS.

As for the injectors, as these the Siemens Deka long 60's? Also referred to as Mototrons. If so let me know the fuel pressure and I'll calc the injector compensation values and post them.

That will make getting your engine to idle properly much easier.

RBob.

Thanks!

#3997

Re: Commanded vs Actual Timing

The timing light could be off.

It is best to set the base timing with the engine fully warmed up.

Last is the ICM latency, this can cause the timing to be off by quite a bit. See this thread:

https://www.thirdgen.org/forums/diy-...ncy-table.html

RBob.

It is best to set the base timing with the engine fully warmed up.

Last is the ICM latency, this can cause the timing to be off by quite a bit. See this thread:

https://www.thirdgen.org/forums/diy-...ncy-table.html

RBob.

I read thru the Latency threads. My head is spinning.

Is there a way to figure out what latency values I should be using, other than trial and error?? The BIN I started with was from a V6, but this engine I'm tuning is a 4 banger, I've changed the basics like number of cylinders, BPC, etc, but I haven't touched the SA - Latency table at all.

#3998

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Tuning with the EBL

Injector Data Sheet: FI114961, 60 #/hr Deka Mototron 006

Fuel Pressure: 45 psi

Flow rate: 63.8 #/hr

Minimum PW @ 45 psi: 1498 usec

Offset Compensation versus Battery Voltage:

6.4 Volts: 2464 usec

8.0 Volts: 1552 usec

9.6 Volts: 1072 usec

11.2 Volts: 790 usec

12.8 Volts: 583 usec * also use in the 0 volt row

14.4 Volts: 397 usec

15.0 Volts: 336 usec *extrapolate out to higher voltage entries

Short PW Compensation versus Pulse Width:

*zero this table, can't enter negative values*

RBob.

#3999

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,401

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: Commanded vs Actual Timing

That thread isn't the easiest to follow.

Best way is to do what Cowboy and I did. Make up a BIN with a set 20* across the board. Mark the damper and run the timing light across the RPM range.

Note that if are running DIS a dial back light can't be used. I mention this as many 4's run waste-spark.

RBob.

Is there a way to figure out what latency values I should be using, other than trial and error?? The BIN I started with was from a V6, but this engine I'm tuning is a 4 banger...

Note that if are running DIS a dial back light can't be used. I mention this as many 4's run waste-spark.

RBob.

#4000

Member

Join Date: Mar 2004

Location: Fremont, Ca

Posts: 110

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 IROC-Z Convertable

Engine: 350 Cam, Heads, Heders...etc.

Transmission: 700-r4 "Raptor"

Re: Tuning with the EBL

Here are the values to use:

Injector Data Sheet: FI114961, 60 #/hr Deka Mototron 006

Fuel Pressure: 45 psi

Flow rate: 63.8 #/hr

Minimum PW @ 45 psi: 1498 usec

Offset Compensation versus Battery Voltage:

6.4 Volts: 2464 usec

8.0 Volts: 1552 usec

9.6 Volts: 1072 usec

11.2 Volts: 790 usec

12.8 Volts: 583 usec * also use in the 0 volt row

14.4 Volts: 397 usec

15.0 Volts: 336 usec *extrapolate out to higher voltage entries

Short PW Compensation versus Pulse Width:

*zero this table, can't enter negative values*

RBob.

Injector Data Sheet: FI114961, 60 #/hr Deka Mototron 006

Fuel Pressure: 45 psi

Flow rate: 63.8 #/hr

Minimum PW @ 45 psi: 1498 usec

Offset Compensation versus Battery Voltage:

6.4 Volts: 2464 usec

8.0 Volts: 1552 usec

9.6 Volts: 1072 usec

11.2 Volts: 790 usec

12.8 Volts: 583 usec * also use in the 0 volt row

14.4 Volts: 397 usec

15.0 Volts: 336 usec *extrapolate out to higher voltage entries

Short PW Compensation versus Pulse Width:

*zero this table, can't enter negative values*

RBob.

As for the E85 looks like you just multiply the calculated value of .6709 for each of the tables. I was being a little OCD and added the column for the Crank AFR to the spread sheet and changed/update the tables to match the current layout I have on ebl though it makes absolutely no difference... its as close to working on the car as I can get in the middle of the night. I posted it here if anyone else wants to use it.

Last edited by bphage; 08-12-2015 at 12:18 AM.