383 flywheel recommendation

#1

Member

Thread Starter

iTrader: (1)

Join Date: Jun 2005

Location: Carmel NY

Posts: 447

Likes: 0

Received 1 Like

on

1 Post

Car: 85 IROC Ht

Engine: 383 carb

Transmission: T56

Axle/Gears: Moser 12 bolt 411

383 flywheel recommendation

I have a external balanced 383 on its way to me . I was wanting to know what kind of flywheel to run. I know the stock style 400 168 tooth fly is 14"od and will not fit in the stock t-5 bell (the one I will be using ) and its starter bolt is different . Aftermarket companies make a external balanced 400 153 tooth (not sure of its OD) for a few hundred bucks . I will have both holes drilled in my block and I do have a Minny starter .Is it a simple as buying one of these smaller 153 tooth flies and will it mess with the balance of the crank.

#2

Junior Member

Join Date: Jul 2008

Location: missouri

Posts: 44

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1989 camaro rs

Engine: 383 stroker

Transmission: t5

Axle/Gears: 4th gen/3.55

Re: 383 flywheel recommendation

I ran into the same problem on my setup, but instead of buying one of those pricey flywheels, i had my rotating assembly internally balanced by a machine shop. so now i can run any internally balanced flywheel or balancer i want. or you can buy the special flywheel if you want.

#6

Member

Thread Starter

iTrader: (1)

Join Date: Jun 2005

Location: Carmel NY

Posts: 447

Likes: 0

Received 1 Like

on

1 Post

Car: 85 IROC Ht

Engine: 383 carb

Transmission: T56

Axle/Gears: Moser 12 bolt 411

Re: 383 flywheel recommendation

84 camaro witch one did you get . Part# please if you have it . I see them on the summit web site , and I think I am going this route.Thanks

Trending Topics

#8

Supreme Member

Join Date: Jun 2005

Location: huntsville, al

Posts: 1,440

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 6.8 HSR N2O

Transmission: TKO 600

Axle/Gears: 9" Moser 3.50 True trac

Re: 383 flywheel recommendation

If you use this balancing adaptor you can just go to jegs and get the standard "replacement" flywheel. It had a very unusuall brand name. Under 100 bucks and make the sales guy (or gal) check the weight on it. They'll tell you that the weight of the flywheel isn't listed but have them check the shipping weight to make sure you get the right one. Mine was the lightweight unit (17#) and it really revs quick.

#9

Member

Thread Starter

iTrader: (1)

Join Date: Jun 2005

Location: Carmel NY

Posts: 447

Likes: 0

Received 1 Like

on

1 Post

Car: 85 IROC Ht

Engine: 383 carb

Transmission: T56

Axle/Gears: Moser 12 bolt 411

Re: 383 flywheel recommendation

I am running a stock t-5 one with my 350 currently. Do you have any vibrations with you plate antman ? part# 2 if you have it .

#10

Supreme Member

Join Date: Jun 2005

Location: huntsville, al

Posts: 1,440

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 6.8 HSR N2O

Transmission: TKO 600

Axle/Gears: 9" Moser 3.50 True trac

Re: 383 flywheel recommendation

I used the balancing plate witha 400 I ran years back. Got L98 350 with T5 and the flywheel mentioned in my IROC. No vibration with either setup though. Planning to go 383 on my next build and will use the balancing plate unless I have the whole assembly balanced. Most 383 kit suppliiers will balance your flywheel with the assembly.

#11

Junior Member

Join Date: Mar 2012

Location: Princeton WV

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1989 Camaro

Engine: 383

Transmission: T5 Borg Warner

Axle/Gears: 4:10

Re: 383 flywheel recommendation

I have a 1989 Camaro RS that was upgraded from a V6 a 383 Stroker prior to me purchasing it. I has a vibration when you rev the engine in any gear and in neutral. I was told when I bought the car that it was the input shaft bearing causing that vibration. I pulled the transmission this weekend and the input shaft doesn't seem to be loose. It turns freely and doesn't appear to have slack in it.

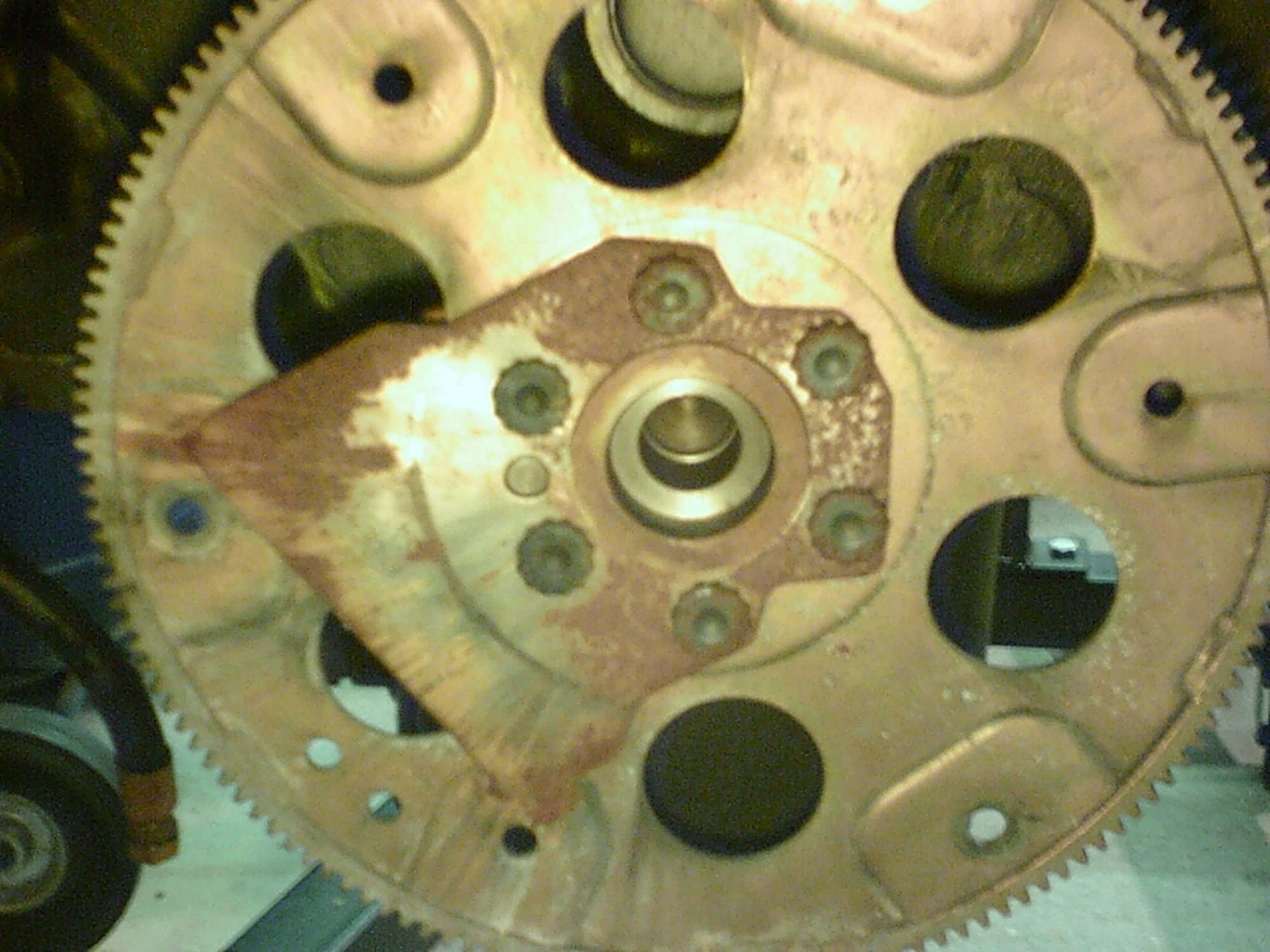

After doing some research, i have read this post and others saying the 383 is an externally balanced engine and requires the flywheel to be externally balanced. I have also read that an externally balanced flywheel has a weight welded on it. The flywheel does not have anything welded on it. The flywheel has a diameter of 12-3/4". Is this the wrong flywheel for a stroker? Could this flywheel be the reasoning behind the vibration? Should I purchase a balancing plate like I have posted below? Could the engine be balanced internally and not be noticeable from the outside?

http://www.ebay.com/itm/New-SBC-Chev...#ht_3954wt_954

After doing some research, i have read this post and others saying the 383 is an externally balanced engine and requires the flywheel to be externally balanced. I have also read that an externally balanced flywheel has a weight welded on it. The flywheel does not have anything welded on it. The flywheel has a diameter of 12-3/4". Is this the wrong flywheel for a stroker? Could this flywheel be the reasoning behind the vibration? Should I purchase a balancing plate like I have posted below? Could the engine be balanced internally and not be noticeable from the outside?

http://www.ebay.com/itm/New-SBC-Chev...#ht_3954wt_954

#12

Supreme Member

Join Date: Jun 2005

Location: huntsville, al

Posts: 1,440

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 6.8 HSR N2O

Transmission: TKO 600

Axle/Gears: 9" Moser 3.50 True trac

Re: 383 flywheel recommendation

Wow, this is an old one...

Anyway, most 383's would be externally balanced. There are eceptions but the original 400 crankshaft they are generally built around is ext bal. I have not yet built a 1-piece rear main 383 so I cant give you the answer. However, if the vibration you are describing is from an imbalance in your rotating assembly then you MUST get this addressed or it will cause problems from premature wear of your main bearings to catastrophic failure!

If memory serves me correctly the one-piece rear main 350's are ext balanced also. Someone may have to correct me on that one but regardless, the flywheel would not be the same for a 350 vs 400 based 383. And on manual transmission flywheels, the weight is generally molded into the engine side, not welded on.

Regarding the bolt in "balancing plate" available for using a 350 flywheel on a 383/400 it may not work if the 350 IS ext bal as suggested above. Check and see because if the 1-piece rear IS NOT ext bal the "plate" would probably work.

Your best bet is to go back to the supplier of your kit and ask. If it was pieced together then use the 400 wheel (or plate) for a 383. Now the issue is "is there a 15x tooth 400 wheel?" Probably not so it will be a purpose-made flywheel. But there were/are a lot of companies making 1-RM 383 components so one of them should be able to direct you.

Far and away the best answer is to have the entire assembly balanced together. If this is not possible then get as close as you can with a plate or flywheel.

Anyway, most 383's would be externally balanced. There are eceptions but the original 400 crankshaft they are generally built around is ext bal. I have not yet built a 1-piece rear main 383 so I cant give you the answer. However, if the vibration you are describing is from an imbalance in your rotating assembly then you MUST get this addressed or it will cause problems from premature wear of your main bearings to catastrophic failure!

If memory serves me correctly the one-piece rear main 350's are ext balanced also. Someone may have to correct me on that one but regardless, the flywheel would not be the same for a 350 vs 400 based 383. And on manual transmission flywheels, the weight is generally molded into the engine side, not welded on.

Regarding the bolt in "balancing plate" available for using a 350 flywheel on a 383/400 it may not work if the 350 IS ext bal as suggested above. Check and see because if the 1-piece rear IS NOT ext bal the "plate" would probably work.

Your best bet is to go back to the supplier of your kit and ask. If it was pieced together then use the 400 wheel (or plate) for a 383. Now the issue is "is there a 15x tooth 400 wheel?" Probably not so it will be a purpose-made flywheel. But there were/are a lot of companies making 1-RM 383 components so one of them should be able to direct you.

Far and away the best answer is to have the entire assembly balanced together. If this is not possible then get as close as you can with a plate or flywheel.

Last edited by antman89iroc; 03-13-2012 at 09:36 AM.

#13

Member

Join Date: Aug 2010

Location: south east north dakota

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1985 Z28/1981 Z28

Engine: 85 383 stroker/81 350

Transmission: 85 fortes tko 600 /81 turbo 350

Axle/Gears: G P ford 9" in proces

Re: 383 flywheel recommendation

my 383 is a two peice and internal balance.i found this out when installing the flywheel. if your tranny is out start the engine and see if it vibrates,if so you know to get a flywheel.there is a few different weights you can get to balance it out i talked to summit for their advise on what counter weights i needed before i knew it was internal

#14

Member

Join Date: Feb 2012

Location: San Tan Valley, AZ

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

Car: 92 25th anniversary edition

Engine: 305

Transmission: 700R-4

Axle/Gears: 2.73's

Re: 383 flywheel recommendation

I did a 383 stroker for my old 89 camaro and bought a Scat rotating assembly for the one piece rear seal. I used the 153 tooth flexplate(only because that's what came in the car) and cut off the counterweight and had the whole rotating assembly balanced. Even went so far as to have the flexplate neutral balanced so if for any reason I need to replace the flexplate I just cut off the counterweight and bolted it on. As for your engine it should have been balanced with the correct flexplate/flywheel. Call your machine shop/engine builder and ask how he balanced it and with which flex/flywheel.

#16

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,030

Received 1,664 Likes

on

1,262 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 383 flywheel recommendation

Same as any other SBC 383...

Either it's internally balanced, in which case you'll need the one for a 350; or it's externally balanced, in which case all bets are off although the stock unbalance for a 400 (roughly 24in-oz opposite the #7/8 rod journal) would be a good place to start.

Either it's internally balanced, in which case you'll need the one for a 350; or it's externally balanced, in which case all bets are off although the stock unbalance for a 400 (roughly 24in-oz opposite the #7/8 rod journal) would be a good place to start.

#17

Re: 383 flywheel recommendation

Same as any other SBC 383...

Either it's internally balanced, in which case you'll need the one for a 350; or it's externally balanced, in which case all bets are off although the stock unbalance for a 400 (roughly 24in-oz opposite the #7/8 rod journal) would be a good place to start.

Either it's internally balanced, in which case you'll need the one for a 350; or it's externally balanced, in which case all bets are off although the stock unbalance for a 400 (roughly 24in-oz opposite the #7/8 rod journal) would be a good place to start.

I have this crankshaft and this Harmonic Balancer.

The description of the Crank says "Internal/External Balance", currently I have a stock 350 flywheel and it vibrates.

What should I do?

Thank you!

Last edited by Danil Netu; 08-24-2020 at 09:53 PM.

#18

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,030

Received 1,664 Likes

on

1,262 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 383 flywheel recommendation

Call Scat and find out what that's supposed to mean. Cranks are INTERNALLY balanced, or they're NOT. Being a 1-pc crank, which for a 305 or 350 is INTERNALLY balanced even though the rearmost bit of INTERNAL balance weight is mounted on the flywheel which makes it look "external" to the untrained and inexperienced eye, they MIGHT mean that it's supposed to use a stock 350 balancer & flywheel; which since it's for 5.7" rods, is a possibility. Then call whoever built your motor and find out what rods and what pistons they used, then find out what the big end and small ends of the rods weigh, and what the pistons weigh. Then call whoever balanced it and find out how they set it up. (bob weight etc.) Once you get all that info, you might be closer to an answer.

Not finding that ATI # anywhere.

Alot of course depends on how bad the vibe is.

There are SO MANY things that can happen building a 383, the mind boggles. Every combo is different. It's not like, you just buy some pile of parts and slap it together, and then try to fix a vibe once it's running... once it's together, it's too late.

Not finding that ATI # anywhere.

Alot of course depends on how bad the vibe is.

There are SO MANY things that can happen building a 383, the mind boggles. Every combo is different. It's not like, you just buy some pile of parts and slap it together, and then try to fix a vibe once it's running... once it's together, it's too late.

#19

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 383 flywheel recommendation

Great.

I have this crankshaft and this Harmonic Balancer.

The description of the Crank says "Internal/External Balance", currently I have a stock 350 flywheel and it vibrates.

What should I do?

Thank you!

I have this crankshaft and this Harmonic Balancer.

The description of the Crank says "Internal/External Balance", currently I have a stock 350 flywheel and it vibrates.

What should I do?

Thank you!

I had to go through all of this with my 334. It's the same rotation assembly as a 383, just with the smaller bores of the 305 block.

I ended up using a 153 tooth (12.75") flexplate and the added counter-balance plate.

You usually put it between the crank flange and the flexplate. I spot welded mine to the other side because I didn't want to move the location of the ring gear teeth and end up with starter engagement problems.

Last edited by NoEmissions84TA; 08-24-2020 at 10:40 PM.

#21

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,030

Received 1,664 Likes

on

1,262 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 383 flywheel recommendation

Probably better to buy the weight... easier to change later on if it isn't right, or if you make other changes.

OTOH there's no guarantee whatsoever that any kind of a stock imbalance, including what the pork-chop weight creates, is what YOUR motor actually needs. The rod total weight, big end weight, small end weight, piston weight, and crank bob weight all have an impact on that. Even if you know ONE of those things, let's say the crank bob weights (which you can probably get from the mfr), that's not enough to be accurate about the balance of the WHOLE motor. But, you can try it and see, and if it doesn't work, try something else. That's why the weight is probably a better idea. Beats buying a half-dozen flywheels until you luck onto one that's right.

I've posted about a million times on here that the best way to set up a motor's balance is STOCK. No other word should EVER be used. Eff "internal" and "external": the true meaning of the words has got lost in the confusion, and doesn't necessarily mean the right thing outside of a classroom for a 1-pc RMS motor anyway. The word is STOCK. If you take your rotating assy to the balance shop and say "here, make this STOCK", there's NO CONFUSION WHATSOEVER. Furthermore, you end up with the ability to interchange anything anytime for any reason, at will... if your stick-shift car gets wrecked and you buy one with an auto trans, your STOCK balanced motor will bolt right onto it; if your flywheel or crank damper gets damaged somehow, a STOCK one will replace it; and so on. For that same reason I tell people to NEVER EVER EVER AT ANY TIME FOR ANY REASON EVER WHATSOEVER let your crank damper and flywheel step foot into the same shop at the same time as the rotating assembly; because the temptation to the shop is TOO GREAT TO RESIST, to pretend to make it all "right" by carving on the damper & FW (eeeeeezy) while leaving the motor weird (because fixing THAT is time consuming and labor intensive). What was it Dumbledore said, something like "soon we must all choose between what is right and what is easy". Words of wisdom. So, you get your rotating assy balanced to the STOCK spec, whatever that is for the motor you're building; and you buy STOCK external parts and just bolt em on. Have those trimmed up to EXACTLY the STOCK spec if necessary or desired, for example the SBC 400 STOCK FW is 24 oz-in more or less unbalanced directly opposite the #7/8 rod journal or the 454 is 28 more or less in the same place, so have the shop set your flywheel up to the STOCK spec for the motor you're building by, for example, bolting a known good STOCK one on it back-to-back and adjusting on the one under adjustment until the pair is neutral.

But it's too late for that now. That has to be done BEFORE the motor is assembled. The best you can do now is chase around whatever it happened to come in at until it runs smooth enough to tolerate. Who knows, might be REAL easy and you'll hit it perfect the first time; I hope so; but I learned a LONG TIME AGO, the HARD WAY I might point out since it was before Algore invented the Interwebz, that hope isn't a very good business (or battle, or construction, or anything else) plan.

OTOH there's no guarantee whatsoever that any kind of a stock imbalance, including what the pork-chop weight creates, is what YOUR motor actually needs. The rod total weight, big end weight, small end weight, piston weight, and crank bob weight all have an impact on that. Even if you know ONE of those things, let's say the crank bob weights (which you can probably get from the mfr), that's not enough to be accurate about the balance of the WHOLE motor. But, you can try it and see, and if it doesn't work, try something else. That's why the weight is probably a better idea. Beats buying a half-dozen flywheels until you luck onto one that's right.

I've posted about a million times on here that the best way to set up a motor's balance is STOCK. No other word should EVER be used. Eff "internal" and "external": the true meaning of the words has got lost in the confusion, and doesn't necessarily mean the right thing outside of a classroom for a 1-pc RMS motor anyway. The word is STOCK. If you take your rotating assy to the balance shop and say "here, make this STOCK", there's NO CONFUSION WHATSOEVER. Furthermore, you end up with the ability to interchange anything anytime for any reason, at will... if your stick-shift car gets wrecked and you buy one with an auto trans, your STOCK balanced motor will bolt right onto it; if your flywheel or crank damper gets damaged somehow, a STOCK one will replace it; and so on. For that same reason I tell people to NEVER EVER EVER AT ANY TIME FOR ANY REASON EVER WHATSOEVER let your crank damper and flywheel step foot into the same shop at the same time as the rotating assembly; because the temptation to the shop is TOO GREAT TO RESIST, to pretend to make it all "right" by carving on the damper & FW (eeeeeezy) while leaving the motor weird (because fixing THAT is time consuming and labor intensive). What was it Dumbledore said, something like "soon we must all choose between what is right and what is easy". Words of wisdom. So, you get your rotating assy balanced to the STOCK spec, whatever that is for the motor you're building; and you buy STOCK external parts and just bolt em on. Have those trimmed up to EXACTLY the STOCK spec if necessary or desired, for example the SBC 400 STOCK FW is 24 oz-in more or less unbalanced directly opposite the #7/8 rod journal or the 454 is 28 more or less in the same place, so have the shop set your flywheel up to the STOCK spec for the motor you're building by, for example, bolting a known good STOCK one on it back-to-back and adjusting on the one under adjustment until the pair is neutral.

But it's too late for that now. That has to be done BEFORE the motor is assembled. The best you can do now is chase around whatever it happened to come in at until it runs smooth enough to tolerate. Who knows, might be REAL easy and you'll hit it perfect the first time; I hope so; but I learned a LONG TIME AGO, the HARD WAY I might point out since it was before Algore invented the Interwebz, that hope isn't a very good business (or battle, or construction, or anything else) plan.

Last edited by sofakingdom; 08-25-2020 at 07:19 PM.

#22

Re: 383 flywheel recommendation

Probably better to buy the weight... easier to change later on if it isn't right, or if you make other changes.

OTOH there's no guarantee whatsoever that any kind of a stock imbalance, including what the pork-chop weight creates, is what YOUR motor actually needs. The rod total weight, big end weight, small end weight, piston weight, and crank bob weight all have an impact on that. Even if you know ONE of those things, let's say the crank bob weights (which you can probably get from the mfr), that's not enough to be accurate about the balance of the WHOLE motor. But, you can try it and see, and if it doesn't work, try something else. That's why the weight is probably a better idea. Beats buying a half-dozen flywheels until you luck onto one that's right.

OTOH there's no guarantee whatsoever that any kind of a stock imbalance, including what the pork-chop weight creates, is what YOUR motor actually needs. The rod total weight, big end weight, small end weight, piston weight, and crank bob weight all have an impact on that. Even if you know ONE of those things, let's say the crank bob weights (which you can probably get from the mfr), that's not enough to be accurate about the balance of the WHOLE motor. But, you can try it and see, and if it doesn't work, try something else. That's why the weight is probably a better idea. Beats buying a half-dozen flywheels until you luck onto one that's right.

I have the bob weight 1750gr.

I also found a receipt from the shop where the motor was balanced 15 years ago. Going to call them tomorrow.

Called Scat and CNC motorsport and they said that the stock flywheel is externally balanced and I probably need an internally balanced flywheel.

Thank you for your support!

#23

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,030

Received 1,664 Likes

on

1,262 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 383 flywheel recommendation

The flywheel and flex plate balance the same way, so other than installation details, it works out the same.

Your motor is INTERNALLY balanced (there's enough room under a 5.7" rod for enough counterweight to correctly offset the weight of the rod & piston), which is what the 5700 in its part # means; but since it's a 1-pc rear main seal, the flange is ROUND, and therefore can't have the last little bit of INTERNAL counterweight that needs to go on it, made as part of the flange. A stock 400 crank had the same stroke as your 383 of 3.75", but because it was made to go with the same ring package as the 350, the piston had to be too tall for a 5.700" rod to work in it, without (in the factory's opinion) compromising the ring package. So they made the rod shorter, at 5.565". BUTT... that left the piston so close to the crank that at BDC there wasn't enough room for enough counterweight, so they "flat cut" across the counterweight. If you know what you're looking at you can spot a 400 crank next to a 350 one from 100 yards away because of that. Your crank however is made for 5.700" rods, meaning it has enough room to be INTERNALLY balanced; but that means stock pistons can't be used. They have to be "special" 383 pistons, with the rings moved up closer to the top of the piston, and/or closer together, and/or thinner, and/or the pin going through the rings and thereby requiring a short pin and a "support" thing in the pin bore to hold the rings.

The funky shape of the flange is the counterweight. Obviously a round flange can't have that. So they moved that rearmost bit of INTERNAL weight to the FW (or FP as the case may be). Just because the weight isn't physically part of the crank, or because it's on the opposite side of the seal, doesn't make the engine balance "external". Meanwhile, the 2-pc FW or FP for ALL 2-pc RMS SBCs except the 400 was NEUTRAL balance, whereas the one for the 1-pc design, even though it's INTERNALLY balanced, has weight on it. That's why those words cause such MASSIVE confusion.

Balancing a motor is far more complicated than it looks to the uninitiated once you deviate from stock parts, if you've never done it.

Butt hay, with luck, the pork chop weight will be close enough to work for you. Maybe that's what Scat intended, I don't know.

Your motor is INTERNALLY balanced (there's enough room under a 5.7" rod for enough counterweight to correctly offset the weight of the rod & piston), which is what the 5700 in its part # means; but since it's a 1-pc rear main seal, the flange is ROUND, and therefore can't have the last little bit of INTERNAL counterweight that needs to go on it, made as part of the flange. A stock 400 crank had the same stroke as your 383 of 3.75", but because it was made to go with the same ring package as the 350, the piston had to be too tall for a 5.700" rod to work in it, without (in the factory's opinion) compromising the ring package. So they made the rod shorter, at 5.565". BUTT... that left the piston so close to the crank that at BDC there wasn't enough room for enough counterweight, so they "flat cut" across the counterweight. If you know what you're looking at you can spot a 400 crank next to a 350 one from 100 yards away because of that. Your crank however is made for 5.700" rods, meaning it has enough room to be INTERNALLY balanced; but that means stock pistons can't be used. They have to be "special" 383 pistons, with the rings moved up closer to the top of the piston, and/or closer together, and/or thinner, and/or the pin going through the rings and thereby requiring a short pin and a "support" thing in the pin bore to hold the rings.

The funky shape of the flange is the counterweight. Obviously a round flange can't have that. So they moved that rearmost bit of INTERNAL weight to the FW (or FP as the case may be). Just because the weight isn't physically part of the crank, or because it's on the opposite side of the seal, doesn't make the engine balance "external". Meanwhile, the 2-pc FW or FP for ALL 2-pc RMS SBCs except the 400 was NEUTRAL balance, whereas the one for the 1-pc design, even though it's INTERNALLY balanced, has weight on it. That's why those words cause such MASSIVE confusion.

Balancing a motor is far more complicated than it looks to the uninitiated once you deviate from stock parts, if you've never done it.

Butt hay, with luck, the pork chop weight will be close enough to work for you. Maybe that's what Scat intended, I don't know.

#24

Re: 383 flywheel recommendation

The flywheel and flex plate balance the same way, so other than installation details, it works out the same.

Your motor is INTERNALLY balanced (there's enough room under a 5.7" rod for enough counterweight to correctly offset the weight of the rod & piston), which is what the 5700 in its part # means; but since it's a 1-pc rear main seal, the flange is ROUND, and therefore can't have the last little bit of INTERNAL counterweight that needs to go on it, made as part of the flange. A stock 400 crank had the same stroke as your 383 of 3.75", but because it was made to go with the same ring package as the 350, the piston had to be too tall for a 5.700" rod to work in it, without (in the factory's opinion) compromising the ring package. So they made the rod shorter, at 5.565". BUTT... that left the piston so close to the crank that at BDC there wasn't enough room for enough counterweight, so they "flat cut" across the counterweight. If you know what you're looking at you can spot a 400 crank next to a 350 one from 100 yards away because of that. Your crank however is made for 5.700" rods, meaning it has enough room to be INTERNALLY balanced; but that means stock pistons can't be used. They have to be "special" 383 pistons, with the rings moved up closer to the top of the piston, and/or closer together, and/or thinner, and/or the pin going through the rings and thereby requiring a short pin and a "support" thing in the pin bore to hold the rings.

The funky shape of the flange is the counterweight. Obviously a round flange can't have that. So they moved that rearmost bit of INTERNAL weight to the FW (or FP as the case may be). Just because the weight isn't physically part of the crank, or because it's on the opposite side of the seal, doesn't make the engine balance "external". Meanwhile, the 2-pc FW or FP for ALL 2-pc RMS SBCs except the 400 was NEUTRAL balance, whereas the one for the 1-pc design, even though it's INTERNALLY balanced, has weight on it. That's why those words cause such MASSIVE confusion.

Balancing a motor is far more complicated than it looks to the uninitiated once you deviate from stock parts, if you've never done it.

Butt hay, with luck, the pork chop weight will be close enough to work for you. Maybe that's what Scat intended, I don't know.

Your motor is INTERNALLY balanced (there's enough room under a 5.7" rod for enough counterweight to correctly offset the weight of the rod & piston), which is what the 5700 in its part # means; but since it's a 1-pc rear main seal, the flange is ROUND, and therefore can't have the last little bit of INTERNAL counterweight that needs to go on it, made as part of the flange. A stock 400 crank had the same stroke as your 383 of 3.75", but because it was made to go with the same ring package as the 350, the piston had to be too tall for a 5.700" rod to work in it, without (in the factory's opinion) compromising the ring package. So they made the rod shorter, at 5.565". BUTT... that left the piston so close to the crank that at BDC there wasn't enough room for enough counterweight, so they "flat cut" across the counterweight. If you know what you're looking at you can spot a 400 crank next to a 350 one from 100 yards away because of that. Your crank however is made for 5.700" rods, meaning it has enough room to be INTERNALLY balanced; but that means stock pistons can't be used. They have to be "special" 383 pistons, with the rings moved up closer to the top of the piston, and/or closer together, and/or thinner, and/or the pin going through the rings and thereby requiring a short pin and a "support" thing in the pin bore to hold the rings.

The funky shape of the flange is the counterweight. Obviously a round flange can't have that. So they moved that rearmost bit of INTERNAL weight to the FW (or FP as the case may be). Just because the weight isn't physically part of the crank, or because it's on the opposite side of the seal, doesn't make the engine balance "external". Meanwhile, the 2-pc FW or FP for ALL 2-pc RMS SBCs except the 400 was NEUTRAL balance, whereas the one for the 1-pc design, even though it's INTERNALLY balanced, has weight on it. That's why those words cause such MASSIVE confusion.

Balancing a motor is far more complicated than it looks to the uninitiated once you deviate from stock parts, if you've never done it.

Butt hay, with luck, the pork chop weight will be close enough to work for you. Maybe that's what Scat intended, I don't know.

The stock 350 flywheel is externally balanced, correct? That's what they said at the cnc-motorsports.

What flywheel would you recommend for my application?

Thread

Thread Starter

Forum

Replies

Last Post

phealinphine69

Tech / General Engine

12

05-11-2006 03:22 PM

REALPOWER

Tech / General Engine

5

12-20-2005 02:18 PM

spills

Tech / General Engine

4

09-20-2005 07:30 AM