T-56 clutch fork won't go on?!?!?!?

#1

Member

Thread Starter

Join Date: May 2001

Location: jacksonville

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

T-56 clutch fork won't go on?!?!?!?

does anybody have any suggestions? i have the tranny bolted to the bellhousing, but the fork just won't go on the bearing. i tried turning the engine over to move the bearing to that flat spot, but it just doesn't seem to work. please help. i want to be able to drive my thirdgen again

#3

Supreme Member

Join Date: Jan 2001

Location: Rock Hill, SC

Posts: 1,411

Likes: 0

Received 3 Likes

on

3 Posts

Car: 1999 Pontiac T/A Firehawk

Engine: ***'s Engine

Transmission: T56

Sounds like you might have the wrong throwout bearing. The T5 bearing I had had no "flat spot", it was completely round. The T56 bearing is sort of square shaped...

#4

Supreme Member

iTrader: (2)

Join Date: Jan 2001

Location: Tampa, FL, USA

Posts: 4,149

Likes: 0

Received 2 Likes

on

2 Posts

Car: 93 240SX

Engine: LQ9

Transmission: T56

Axle/Gears: 3.54 R200 IRS

Shouldnt be able to have the wrong t/o bearing, the LT1 its part of the press plate... unless you tried to use a T5 clutch :-/ .....

#5

Senior Member

Join Date: Feb 2000

Location: College Station/Spring, TX

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

the fork wont go on at all? can you get a picture of this? what exactly is it doing, besides not going on. i am not sure about this but i dont think the fork slides on all the way, i couldnt get it to reach all the way on mine when i "test" fitted my clutch,flywheel,PP.

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

#6

Member

iTrader: (2)

Join Date: Jul 1999

Location: Lynn Haven/Panama City, FL, USA

Posts: 163

Likes: 0

Received 0 Likes

on

0 Posts

Car: 88 Monte SS

Engine: Super-rammed L-98 383

Transmission: T-56 6-Speed

Axle/Gears: 8.5" G-BODY G-80 3.73

The LT-1 T.O.B. is the one with the ROUND clutch fork engagement section, and the TOB can be removed from the PP by simply removing that retention spring. The LT-4 T.O.B. is the one with the SQUARE clutch fork retention section, and is retained in the PP in the same manner as the LT-1 TOB. I haven't used a LT-4 TOB in this application, but I have used LT-4 PP's with LT-1 TOB's all the time. You sure that you have the CLUTCH FORK engaged in the T-NUT properly? This shouldn't be causing such a problem unless something is actually wrong. The best bet is to just remove the gearbox again and check things out. HTH's

------------------

88 Monte SS 355 TPI/LT-4 HOT CAM/Fully ported 1990 Corvette L-98 heads/AFR Hydra-rev/ T-56 6-Speed/ PRO-5.0 shifter/ 1-3/4" full length headers/3" X-PIPE assembly/ 8.5" G-80 rear with 3.73 gears.

http://community.webshots.com/user/ssynergy

www.y-t-g.com/88monte

------------------

88 Monte SS 355 TPI/LT-4 HOT CAM/Fully ported 1990 Corvette L-98 heads/AFR Hydra-rev/ T-56 6-Speed/ PRO-5.0 shifter/ 1-3/4" full length headers/3" X-PIPE assembly/ 8.5" G-80 rear with 3.73 gears.

http://community.webshots.com/user/ssynergy

www.y-t-g.com/88monte

#7

Member

Thread Starter

Join Date: May 2001

Location: jacksonville

Posts: 150

Likes: 0

Received 0 Likes

on

0 Posts

wel i know that i haqve the throughout bearing that has a flat side. when i put the clutch in i made sure that the flat side was so that i could slide the fork on when the time came. well when the time came it wouldn't go on. it just seemed like there was no flat side where i thought. the bearing looked slightly too big. so i cranked the engine over a couple of times while checking in between to see if the flat side had turned to the right spot. but it never did. i guess i'm gonna just have to take the gearbox out again. exactly how should the retaining nut on the fork be? tighten it down all the way or what? thanks for your help guys

Trending Topics

#8

Senior Member

Join Date: Feb 2000

Location: College Station/Spring, TX

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

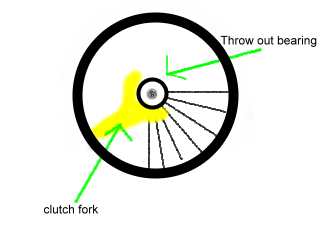

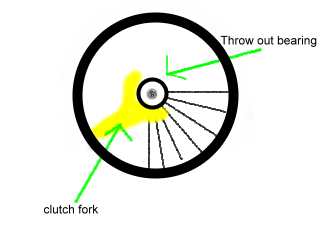

well i got my trans stabbed tonight, boy that sucked. my question is does the fork have to be completely on the TOB? here is a image to show what i mean.sort of.

that is how mine is right now it was as far as i could get it right then, so i gave up for the night and figured i'd ask if it would go further.

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

[This message has been edited by ScreaminDeamin85Z (edited November 01, 2001).]

that is how mine is right now it was as far as i could get it right then, so i gave up for the night and figured i'd ask if it would go further.

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

[This message has been edited by ScreaminDeamin85Z (edited November 01, 2001).]

#9

Senior Member

Join Date: Oct 1999

Location: Dallas, Texas

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Z28

Engine: 5.3 Gen III SBC

Transmission: 4L80E NTC 258mm Stall

Axle/Gears: Trick Chassis 9" 3.50 S-Strac

Ok I know whats wrong. I make sure I have it on before I have it completely stabbed. I when I had mine rebuilt the hicks couldnt get it on by force so they grinded the bellhousing some (so the fork can pull further out and you can get it on the bearing.)

------------------

91 Z28 5.7l Camaro

T-56,McLeod Street Clutch, Cross Drilled Brakes, KYB's,AFPR, 3.73 Gears, Borla Adjustable Cat Back, Hypertech Chip, Hooker Headers.

more to come....

My 91 Z28

------------------

91 Z28 5.7l Camaro

T-56,McLeod Street Clutch, Cross Drilled Brakes, KYB's,AFPR, 3.73 Gears, Borla Adjustable Cat Back, Hypertech Chip, Hooker Headers.

more to come....

My 91 Z28

#11

Senior Member

Join Date: Oct 1999

Location: Dallas, Texas

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Z28

Engine: 5.3 Gen III SBC

Transmission: 4L80E NTC 258mm Stall

Axle/Gears: Trick Chassis 9" 3.50 S-Strac

Well I just had the tip of the input shaft in the pilot bearing and "snaped" the fork on the bearing and continued installing the trans. your fork is unable to pull out enough to get over the throw-out bearings lip right??

------------------

91 Z28 5.7l Camaro

T-56,McLeod Street Clutch, Cross Drilled Brakes, KYB's,AFPR, 3.73 Gears, Borla Adjustable Cat Back, Hypertech Chip, Hooker Headers.

more to come....

My 91 Z28

------------------

91 Z28 5.7l Camaro

T-56,McLeod Street Clutch, Cross Drilled Brakes, KYB's,AFPR, 3.73 Gears, Borla Adjustable Cat Back, Hypertech Chip, Hooker Headers.

more to come....

My 91 Z28

#12

Senior Member

Join Date: Feb 2000

Location: College Station/Spring, TX

Posts: 536

Likes: 0

Received 0 Likes

on

0 Posts

by stabbed he means, tranny to bellhousing attached. i dont think that i can do it like this though, the fork doesnt appear to be long enough. also i dont want to pull the trans away considering how much of PITA it was to get stabbed to begin with.

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

------------------

Brandon

"ScreaminDeamin 360"

350 60 over, TRW forged 9.83:1 pistons,Hooker Comp headers, crane cam 216/228 .484/.512, crane 1.6 RR's, ported plenum, home made ram air, 24lb SVO injectors, crane AFPR, all going through 3 inch mandrel pipe and a flowmaster.

New project-89 IROC-305 5spd...Jamex Springs...and thats just about it!Soon- 6 speed, Pro 5.0 shifter and 4.10's

http://ScreaminDeamin.cz28.com

#13

Senior Member

Join Date: Oct 1999

Location: Dallas, Texas

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Z28

Engine: 5.3 Gen III SBC

Transmission: 4L80E NTC 258mm Stall

Axle/Gears: Trick Chassis 9" 3.50 S-Strac

dont pull it completely away. the only way the people who installed my trans could attach it was by grinding some metal away from the bellhousing so they could pull the clutch fork away just alittle bit.

#15

Senior Member

Join Date: Oct 1999

Location: Dallas, Texas

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Z28

Engine: 5.3 Gen III SBC

Transmission: 4L80E NTC 258mm Stall

Axle/Gears: Trick Chassis 9" 3.50 S-Strac

That should be good if I remember correctly. The edges of the fork should in the middle.

[This message has been edited by Chris Etemadi (edited November 02, 2001).]

[This message has been edited by Chris Etemadi (edited November 02, 2001).]

Thread

Thread Starter

Forum

Replies

Last Post

tonys91rs

Engine/Drivetrain/Suspension Parts for Sale

3

10-10-2015 03:31 PM

mygta87

Engine/Drivetrain/Suspension Wanted

0

09-14-2015 10:36 PM