LO3 Wont stay running.

#1

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

LO3 Wont stay running.

Ok so heres what I have, car developed a issue stalling out at any stop when warm and in gear. Today I swapped the fuel pump and filter out for new ones. Now the car will not idle, it will start and stay running for about 30 seconds and then misfire and die. If you throw it into any gear it will instantely stumble and die. What do you think it could be? I pretty much rule out fuel issues since I just replaced the parts that are common failures. RF Master you out there?

#3

Supreme Member

Re: LO3 Wont stay running.

+1, check fuel pressure. its odd that your problem got worse. check to make sure you didnt kink the fuel line up by the tank. did you check/test the wires going to the pump?

#5

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

Ok so I worked on it somemore today. Replaced IAC and rechecked my work on the fuel pump and filter. Problem persists. I went to test the TPS and the connector and sensor housing was broken exposing metal on the C pin. When I went to remove the TPS one screw came out fine and the other had the head snap off. So question is could this be the issue? Still havent hooked up gauges for fuel pressure to it(i feel confident that it isnt that since i did the pump 2 days ago.). Any Ideas?

#6

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

Hey SS

Pin C is +5 volt reference voltage applied to TPS sensor. Without +5 V applied to TPS ECM is not getting any voltage back from TPS. Disconnect TPS connector from broken TPS and measure DC voltage at pin C with respect to ground or Pin A. Pin C should be gray color wire and Pin A is usually black. TPS output Pin B is usually blue.

I would square away any broken sensor issues first before jumping to conclusion. Your TPS OE #17111787 should be available through any parts house - do not pay more than $40.

//RF

Pin C is +5 volt reference voltage applied to TPS sensor. Without +5 V applied to TPS ECM is not getting any voltage back from TPS. Disconnect TPS connector from broken TPS and measure DC voltage at pin C with respect to ground or Pin A. Pin C should be gray color wire and Pin A is usually black. TPS output Pin B is usually blue.

I would square away any broken sensor issues first before jumping to conclusion. Your TPS OE #17111787 should be available through any parts house - do not pay more than $40.

//RF

#7

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

thanks also I was going to add that if I put any electrical load on the car it will die even if it's and park

Trending Topics

#8

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

Ok RF so i went and played with it some more today. I tested the connector and it was recieving the 5volts at pin C. I then connected the TPS with it off of the throttle body back probbed b and a and manualy moved the lever and it rose from .001 to 5volts at WOT steadily. So those both test fine although I need to replace both anyway due to cracked housings. I had codes 15 and 22 but those are due to me disconnecting those respective sensors while the car was running(TPS, CTS). Also as I was stating with the car warmed up yesterday, I couldnt even fire up the single cooling fan(wired to a switch) without the car stumbling and dying, even in park. So far over the past week ive replaced the fuel pump/filter, IAC, and tested the TPS. Whats left? I also tested the alternator just for giggles and it ran fine. So basically any load on the engine causes it to stumble and die.

#9

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

SS - good Sunday afternoon

When you tested TPS - removed it from TB throttle shaft and manually moved you have measured TPS voltage (Pin B) at it varied between 0.001 and 5 volts. That may be the problem. Engine off, ignition off Check Pin A (ground ) resistance to engine block (or good electrical ground) - it should be near 0 ohms - 1 to 2 Ohms is ok. The TPS voltage should vary between 0.6 at idle and 4.4 to 4.6 at WOT. If you have a missing ground at Pin A the TPS voltage (Pin B when measured against another ground) will show 0 to 5 volt swing! Verify that Pin A is ground connected - IRC that wire uses the ground lug on back side of passenger cylinder head. If the bolt is loose or there is a corrosion that will play havoc with grounds. Also check ground lug next to the thermostat.

Dying under load - check harness ground first before we start chasing any further. If measure 13.4 Vdc at idle alternator is providing charge.

//RF

When you tested TPS - removed it from TB throttle shaft and manually moved you have measured TPS voltage (Pin B) at it varied between 0.001 and 5 volts. That may be the problem. Engine off, ignition off Check Pin A (ground ) resistance to engine block (or good electrical ground) - it should be near 0 ohms - 1 to 2 Ohms is ok. The TPS voltage should vary between 0.6 at idle and 4.4 to 4.6 at WOT. If you have a missing ground at Pin A the TPS voltage (Pin B when measured against another ground) will show 0 to 5 volt swing! Verify that Pin A is ground connected - IRC that wire uses the ground lug on back side of passenger cylinder head. If the bolt is loose or there is a corrosion that will play havoc with grounds. Also check ground lug next to the thermostat.

Dying under load - check harness ground first before we start chasing any further. If measure 13.4 Vdc at idle alternator is providing charge.

//RF

#10

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

SS - good Sunday afternoon

When you tested TPS - removed it from TB throttle shaft and manually moved you have measured TPS voltage (Pin B) at it varied between 0.001 and 5 volts. That may be the problem. Engine off, ignition off Check Pin A (ground ) resistance to engine block (or good electrical ground) - it should be near 0 ohms - 1 to 2 Ohms is ok. The TPS voltage should vary between 0.6 at idle and 4.4 to 4.6 at WOT. If you have a missing ground at Pin A the TPS voltage (Pin B when measured against another ground) will show 0 to 5 volt swing! Verify that Pin A is ground connected - IRC that wire uses the ground lug on back side of passenger cylinder head. If the bolt is loose or there is a corrosion that will play havoc with grounds. Also check ground lug next to the thermostat.

Dying under load - check harness ground first before we start chasing any further. If measure 13.4 Vdc at idle alternator is providing charge.

//RF

When you tested TPS - removed it from TB throttle shaft and manually moved you have measured TPS voltage (Pin B) at it varied between 0.001 and 5 volts. That may be the problem. Engine off, ignition off Check Pin A (ground ) resistance to engine block (or good electrical ground) - it should be near 0 ohms - 1 to 2 Ohms is ok. The TPS voltage should vary between 0.6 at idle and 4.4 to 4.6 at WOT. If you have a missing ground at Pin A the TPS voltage (Pin B when measured against another ground) will show 0 to 5 volt swing! Verify that Pin A is ground connected - IRC that wire uses the ground lug on back side of passenger cylinder head. If the bolt is loose or there is a corrosion that will play havoc with grounds. Also check ground lug next to the thermostat.

Dying under load - check harness ground first before we start chasing any further. If measure 13.4 Vdc at idle alternator is providing charge.

//RF

#11

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

TPS is bad - Pin A within TPS is open internally. Remove TPS from TB and measure resistance between Pin A and C - depending on make it should read about 5.4 to 6.0 kOhm. If you measure very high resistance - it is open circuit and that's the problem.

//RF

//RF

#12

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

okay I'll check that tonight I should mention that with the tps unplugged the car still has similar symptoms having issues staying alive in gear

#13

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

You may have couple of electrical issues, but each in combination is compounding each other. Making sure that TPS is ok will keep ECM delivering correct amount of fuel.

Couple of functional checks - Engine off, ign on - measure coil supply voltage. It should be around 11.5 to 12.0 depending on the battery. With DVM connected flip cooling fans on and observe how low the the voltage drops. Repeat the same test with engine idling.

Question - how the cooling fans are wired? These fans draw a lot current on start up (30 Amp of surge current is typical) Ideally a relay should be used to provide power from battery post.

//RF

Couple of functional checks - Engine off, ign on - measure coil supply voltage. It should be around 11.5 to 12.0 depending on the battery. With DVM connected flip cooling fans on and observe how low the the voltage drops. Repeat the same test with engine idling.

Question - how the cooling fans are wired? These fans draw a lot current on start up (30 Amp of surge current is typical) Ideally a relay should be used to provide power from battery post.

//RF

#14

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

You may have couple of electrical issues, but each in combination is compounding each other. Making sure that TPS is ok will keep ECM delivering correct amount of fuel.

Couple of functional checks - Engine off, ign on - measure coil supply voltage. It should be around 11.5 to 12.0 depending on the battery. With DVM connected flip cooling fans on and observe how low the the voltage drops. Repeat the same test with engine idling.

Question - how the cooling fans are wired? These fans draw a lot current on start up (30 Amp of surge current is typical) Ideally a relay should be used to provide power from battery post.

//RF

Couple of functional checks - Engine off, ign on - measure coil supply voltage. It should be around 11.5 to 12.0 depending on the battery. With DVM connected flip cooling fans on and observe how low the the voltage drops. Repeat the same test with engine idling.

Question - how the cooling fans are wired? These fans draw a lot current on start up (30 Amp of surge current is typical) Ideally a relay should be used to provide power from battery post.

//RF

#15

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

UPDATE-Just incase any of you are following this thread heres an update.

RF and myself have been diagnosing this car for a couple days now with no luck. Checked fuel pressure today and it held steady at 11psi. We tested or replaced the following sensors and verified they are within parameters- Throttle Position, Idle Air Control, Coolant Temperature, Manifold Air Pressure. If anybody has something good to through at us let us know. RF is going to be coming out later on today to hook up the ALDL cable to get some readings and check timing.

RF and myself have been diagnosing this car for a couple days now with no luck. Checked fuel pressure today and it held steady at 11psi. We tested or replaced the following sensors and verified they are within parameters- Throttle Position, Idle Air Control, Coolant Temperature, Manifold Air Pressure. If anybody has something good to through at us let us know. RF is going to be coming out later on today to hook up the ALDL cable to get some readings and check timing.

#16

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

UPDATE- RF hooked up the computer to the ECM and guess what. ECM shows all sensors are fine and right on point! At this point we have little idea what it could be. There not much left, just the ignition system. He notice the car tends to start having issues after it warms up. On a cold start she will idle fine, but it will still die if you put it in gear. Any ideas?

#20

Member

iTrader: (1)

Join Date: Mar 2010

Location: Sunrise, Florida

Posts: 482

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Camaro Z28

Engine: 5.0 LB9 TPI

Transmission: 700r4

Axle/Gears: 2.73 posi drum

Re: LO3 Wont stay running.

Just to ask, when did this problem show up? Anthing unusual happen before the car started stalling?

#22

Member

iTrader: (1)

Join Date: Mar 2010

Location: Sunrise, Florida

Posts: 482

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Camaro Z28

Engine: 5.0 LB9 TPI

Transmission: 700r4

Axle/Gears: 2.73 posi drum

Re: LO3 Wont stay running.

When its in park/neutral how is it? When you put it into gear does, the idle drop and get rough then it dies?

#25

Re: LO3 Wont stay running.

I wasn't asking about the timing, I was telling you that a timing light only flashes when there is spark, so if you loose spark the light wont flash, then it stalls.

This is still a stalling issue , right? You are either loosing spark, fuel pressure, injector pulse,egr sticking open, or an iac issue.

This is still a stalling issue , right? You are either loosing spark, fuel pressure, injector pulse,egr sticking open, or an iac issue.

#27

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

I wasn't asking about the timing, I was telling you that a timing light only flashes when there is spark, so if you loose spark the light wont flash, then it stalls.

This is still a stalling issue , right? You are either loosing spark, fuel pressure, injector pulse,egr sticking open, or an iac issue.

This is still a stalling issue , right? You are either loosing spark, fuel pressure, injector pulse,egr sticking open, or an iac issue.

The car will cold start and idle fine, but if you throw it into gear it will instantly stall. Now when the car reaches operating temperature(starts dropping revs) it will start to develop a bad misfire every couple seconds and recover itself and repeat process. The only constant is that at any time if you put it in gear it will die. ALDL says all the sensors are reading correctly and that the car is running slightly rich. That being said, if I throw it into gear and give it some gas at the same time it will take off but as soon as I slow to less than 5mph it will die. The fuel pump/filter were replaced less than 3 weeks ago and the pressure holds 11psi.

#28

Junior Member

Join Date: Mar 2009

Location: Woodbridge, VA

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 Camaro RS

Engine: 305 TBI

Transmission: 700R4 with B&M shift kit

Axle/Gears: I have no clue

Re: LO3 Wont stay running.

When you having in gear and keeping it over 5 mph, do you have to pump the gas peddle a few times to keep things moving? Reason I'm asking is I had a similar issue with a 92 RS, and found out eventually I had a wiped cam lobe.

#29

Supreme Member

Re: LO3 Wont stay running.

I assume you have learned that fuel pressure has less to do with the pump than with the pressure regulator which is built into the TB. No issue now since you verified pressure within the normal range. I would have tested the TPS on the TB so you could verify minimum and WOT voltages. Thebn use the scan tool to verify that the ECM is seeing the same voltages. This saves alot of unnecessary testing. At this point I would be using a lab scope to verify good clean signals on the coil primary and injector circuits and watching both to see which drops out first. Then I would go to the crank referrence pulse from the ICM to the ECM to see if it's dropping out. Does ECM coolant temp seem to jive with actual engine temp? Is your air pump diverter valve switching from the manifolds to the cat as the engine warms up?

#30

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

I assume you have learned that fuel pressure has less to do with the pump than with the pressure regulator which is built into the TB. No issue now since you verified pressure within the normal range. I would have tested the TPS on the TB so you could verify minimum and WOT voltages. Thebn use the scan tool to verify that the ECM is seeing the same voltages. This saves alot of unnecessary testing. At this point I would be using a lab scope to verify good clean signals on the coil primary and injector circuits and watching both to see which drops out first. Then I would go to the crank referrence pulse from the ICM to the ECM to see if it's dropping out. Does ECM coolant temp seem to jive with actual engine temp? Is your air pump diverter valve switching from the manifolds to the cat as the engine warms up?

#31

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

I assume you have learned that fuel pressure has less to do with the pump than with the pressure regulator which is built into the TB. No issue now since you verified pressure within the normal range. I would have tested the TPS on the TB so you could verify minimum and WOT voltages. Thebn use the scan tool to verify that the ECM is seeing the same voltages. This saves alot of unnecessary testing. At this point I would be using a lab scope to verify good clean signals on the coil primary and injector circuits and watching both to see which drops out first. Then I would go to the crank referrence pulse from the ICM to the ECM to see if it's dropping out. Does ECM coolant temp seem to jive with actual engine temp? Is your air pump diverter valve switching from the manifolds to the cat as the engine warms up?

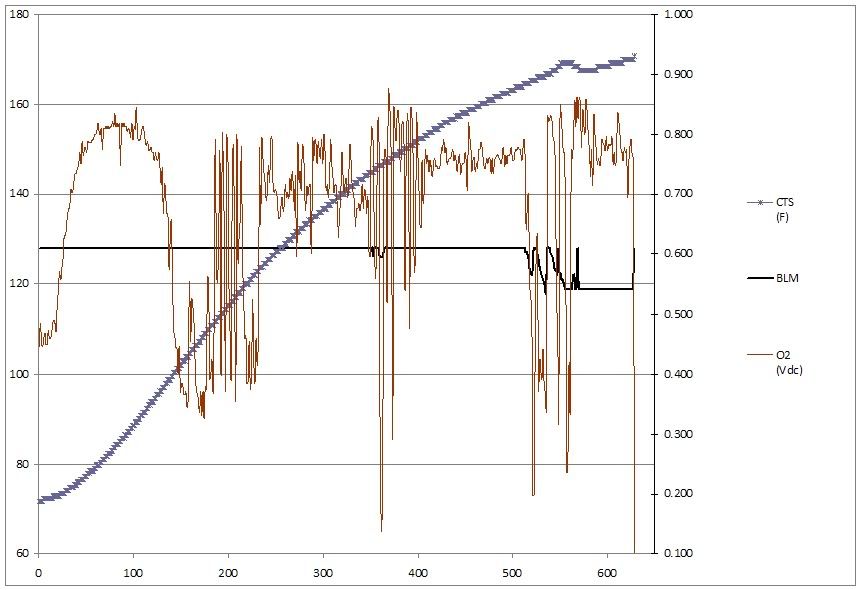

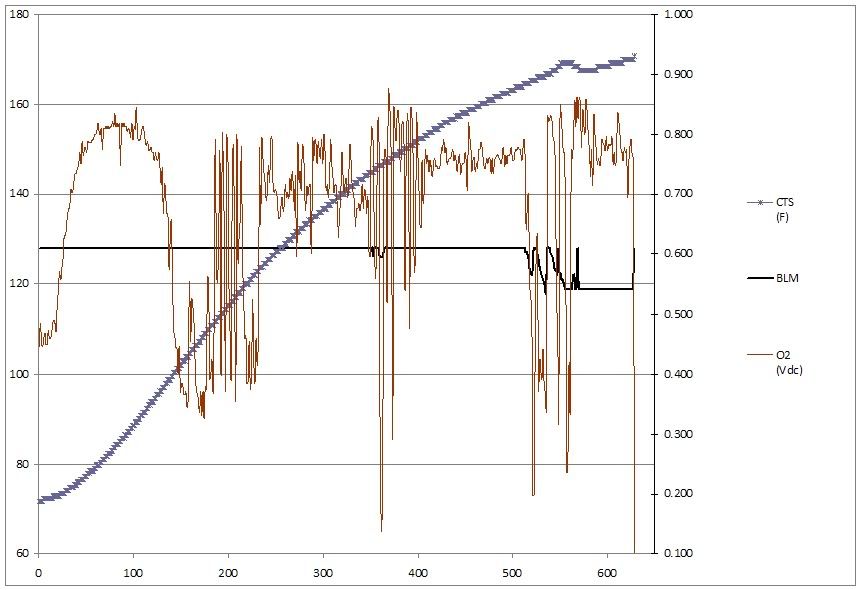

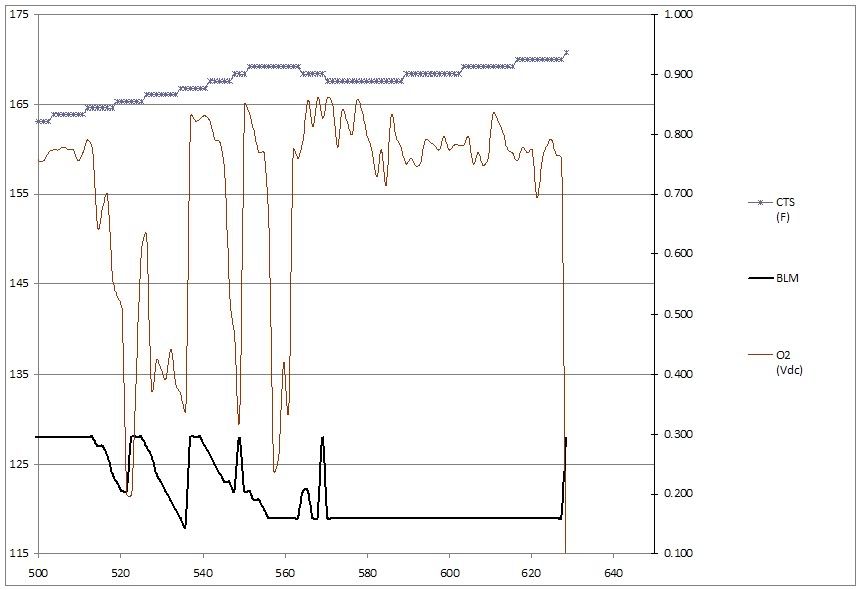

Couple of things that stand out in the data logs.

1) I do not see O2 swinging from rich to lean once engine warms up (in idle). It stays around 700 mV for the most part and BLM seems to trend down to 119.

2)The MAP stays rock steady around around 28 kPa. Somehow there is extra fuel is geting into the engine (leak in injector pod assembly I would suspect???) and INT fails to oscillate. This could be a programmed into his custom chip (stage 4) - I simply do not know.

//RF

#32

Supreme Member

Re: LO3 Wont stay running.

Mitchell shows this car to have a single wire O2(non heated). It's not unusual for it to fall into open loop at idle. In fact, I find that unless I run these motors at 2,500 for several seconds, they tend to stay in open loop. That's something to consider. You may try this test to make sure the system is able to achieve closed loop. Once the system goes closed loop, it should stay in closed loop at idle for some time, until the sensor cools to below 600degrees again. The rich condition could very well be in the tune. How does the oil look? It's not contaminated with fuel is it? Try pulling the PCV valve out of the valve cover and see if the O2 doesn't respond. Again, the system needs to be in closed loop for this test.

The thing that concerns me is that a slight rich condition shouldn't cause the engine to stall as described. The system would have to be pig rich to cause this. Or there is still something else happening here. You were talking earlier about testing the coil output. Have you tried using a cheap KV tester. They are useful for determining coil health. I mentioned a lab scope before. I recognize that these aren't cheap. Though I would bet that you could find a used Snap On Vantage pretty cheap since they have upgraded to the Vantage Pro. In the absence of a lab scope, you can use a DVOM to monitor Crank Referrence. It should read about 2.5v.(its a 0-5v square wave). You can use the DVOM to watch for the signal to drop out before the engine stalls. You can also use the DVOM to monitor injector pulse. It should read about 14v with the engine running. Watch both signals to see which one drops out first. With the system in closed loop, watch O2 voltage as the engine stalls. Is it going rich? To verify MAP accuracy, compare reading with an actual vacuum gauge.

In order for the engine to stall, it has to be losing something. Just need to figure out what.

The thing that concerns me is that a slight rich condition shouldn't cause the engine to stall as described. The system would have to be pig rich to cause this. Or there is still something else happening here. You were talking earlier about testing the coil output. Have you tried using a cheap KV tester. They are useful for determining coil health. I mentioned a lab scope before. I recognize that these aren't cheap. Though I would bet that you could find a used Snap On Vantage pretty cheap since they have upgraded to the Vantage Pro. In the absence of a lab scope, you can use a DVOM to monitor Crank Referrence. It should read about 2.5v.(its a 0-5v square wave). You can use the DVOM to watch for the signal to drop out before the engine stalls. You can also use the DVOM to monitor injector pulse. It should read about 14v with the engine running. Watch both signals to see which one drops out first. With the system in closed loop, watch O2 voltage as the engine stalls. Is it going rich? To verify MAP accuracy, compare reading with an actual vacuum gauge.

In order for the engine to stall, it has to be losing something. Just need to figure out what.

#33

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

Mitchell shows this car to have a single wire O2(non heated). It's not unusual for it to fall into open loop at idle. In fact, I find that unless I run these motors at 2,500 for several seconds, they tend to stay in open loop. That's something to consider. You may try this test to make sure the system is able to achieve closed loop. Once the system goes closed loop, it should stay in closed loop at idle for some time, until the sensor cools to below 600degrees again. The rich condition could very well be in the tune. How does the oil look? It's not contaminated with fuel is it? Try pulling the PCV valve out of the valve cover and see if the O2 doesn't respond. Again, the system needs to be in closed loop for this test.

The thing that concerns me is that a slight rich condition shouldn't cause the engine to stall as described. The system would have to be pig rich to cause this. Or there is still something else happening here. You were talking earlier about testing the coil output. Have you tried using a cheap KV tester. They are useful for determining coil health. I mentioned a lab scope before. I recognize that these aren't cheap. Though I would bet that you could find a used Snap On Vantage pretty cheap since they have upgraded to the Vantage Pro. In the absence of a lab scope, you can use a DVOM to monitor Crank Referrence. It should read about 2.5v.(its a 0-5v square wave). You can use the DVOM to watch for the signal to drop out before the engine stalls. You can also use the DVOM to monitor injector pulse. It should read about 14v with the engine running. Watch both signals to see which one drops out first. With the system in closed loop, watch O2 voltage as the engine stalls. Is it going rich? To verify MAP accuracy, compare reading with an actual vacuum gauge.

In order for the engine to stall, it has to be losing something. Just need to figure out what.

The thing that concerns me is that a slight rich condition shouldn't cause the engine to stall as described. The system would have to be pig rich to cause this. Or there is still something else happening here. You were talking earlier about testing the coil output. Have you tried using a cheap KV tester. They are useful for determining coil health. I mentioned a lab scope before. I recognize that these aren't cheap. Though I would bet that you could find a used Snap On Vantage pretty cheap since they have upgraded to the Vantage Pro. In the absence of a lab scope, you can use a DVOM to monitor Crank Referrence. It should read about 2.5v.(its a 0-5v square wave). You can use the DVOM to watch for the signal to drop out before the engine stalls. You can also use the DVOM to monitor injector pulse. It should read about 14v with the engine running. Watch both signals to see which one drops out first. With the system in closed loop, watch O2 voltage as the engine stalls. Is it going rich? To verify MAP accuracy, compare reading with an actual vacuum gauge.

In order for the engine to stall, it has to be losing something. Just need to figure out what.

#34

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

1) O2 Sensor is a single wire bolted into a stock cast iron manifold. After reviewing data logs it appears that O2 is hot enough as O2 voltage steadily raises during warm-up period and slowly dropping to about 0.500 Volts. This would lead me to believe that O2 is above 600F since a cold O2 would report very low voltage.

2) After warm up period (~2 min of run time) reported BLM clicks down from 128 (open loop warmup) down to 119 counts and stays there. IRC 108 is minimum value for BLM

3) I took a look at #1 plug - it appeared clean enough - slightly rich with hint of oil. As for HV testing - I have several OE coils which can be pressed into swap service if need be.

4) DRP pulse - this is a classic problem. I have seen hot ICM develop intermittent DRP pulse wave forms once they are hot. This is especially true for TPI distributors which sit behind TPI plenum. Not the case here - this is a TBI car, but it is the same part! There is very little air movement back there and I can only guess how hot it gets there. I have a lab scope, but dragging all this equipment out is a bit problematic. Simpler and quicker (and less scientific I admit) is to swap ICM and see if the stumble goes away.

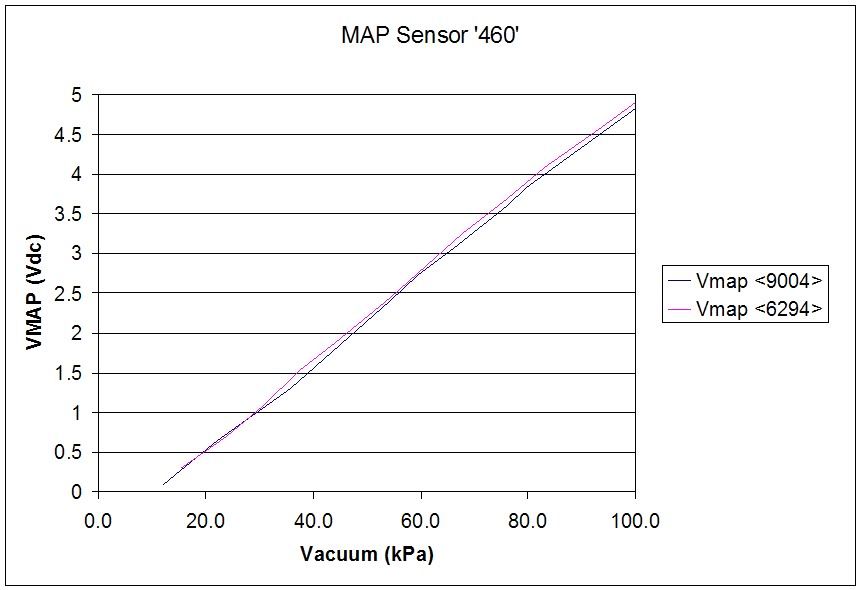

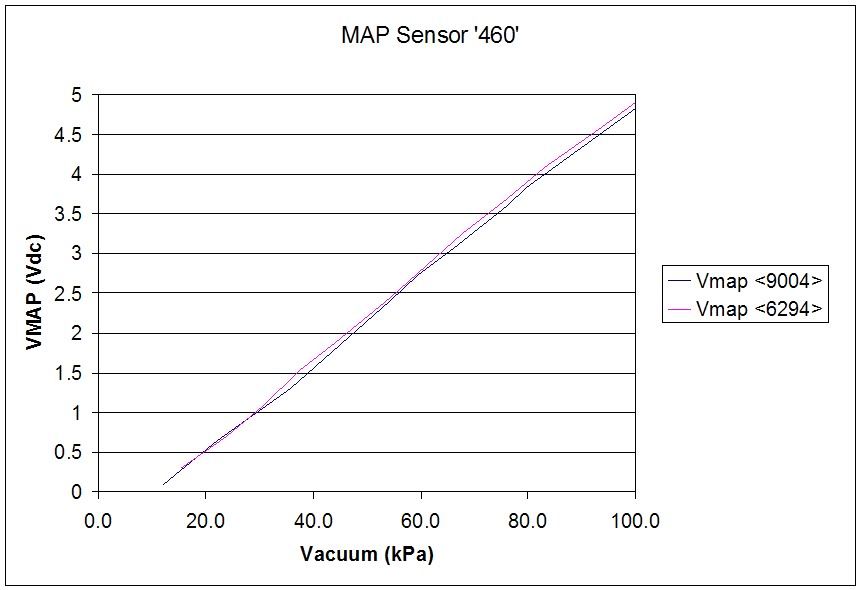

5) MAP sensor that I swapped in was calibrated against vacuum gauge on a test bench. Here is the response curve for this MAP (Plot shows response curves for two different MAP sensors, one of the two was used for verify installed on the car)

My suspicions about 89 Camaro ills :

a) There is uncontrollable extra fuel getting into the engine - possibly leaky fuel injector or a crack in the injector pod.

b) Flaky ICM - once its get hot occasional DRP pulse drop out become persistent and periodic.

Actions going forward - need to review hot data log (been very busy)

//RF

2) After warm up period (~2 min of run time) reported BLM clicks down from 128 (open loop warmup) down to 119 counts and stays there. IRC 108 is minimum value for BLM

3) I took a look at #1 plug - it appeared clean enough - slightly rich with hint of oil. As for HV testing - I have several OE coils which can be pressed into swap service if need be.

4) DRP pulse - this is a classic problem. I have seen hot ICM develop intermittent DRP pulse wave forms once they are hot. This is especially true for TPI distributors which sit behind TPI plenum. Not the case here - this is a TBI car, but it is the same part! There is very little air movement back there and I can only guess how hot it gets there. I have a lab scope, but dragging all this equipment out is a bit problematic. Simpler and quicker (and less scientific I admit) is to swap ICM and see if the stumble goes away.

5) MAP sensor that I swapped in was calibrated against vacuum gauge on a test bench. Here is the response curve for this MAP (Plot shows response curves for two different MAP sensors, one of the two was used for verify installed on the car)

My suspicions about 89 Camaro ills :

a) There is uncontrollable extra fuel getting into the engine - possibly leaky fuel injector or a crack in the injector pod.

b) Flaky ICM - once its get hot occasional DRP pulse drop out become persistent and periodic.

Actions going forward - need to review hot data log (been very busy)

//RF

#35

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

1) O2 Sensor is a single wire bolted into a stock cast iron manifold. After reviewing data logs it appears that O2 is hot enough as O2 voltage steadily raises during warm-up period and slowly dropping to about 0.500 Volts. This would lead me to believe that O2 is above 600F since a cold O2 would report very low voltage.

2) After warm up period (~2 min of run time) reported BLM clicks down from 128 (open loop warmup) down to 119 counts and stays there. IRC 108 is minimum value for BLM

3) I took a look at #1 plug - it appeared clean enough - slightly rich with hint of oil. As for HV testing - I have several OE coils which can be pressed into swap service if need be.

4) DRP pulse - this is a classic problem. I have seen hot ICM develop intermittent DRP pulse wave forms once they are hot. This is especially true for TPI distributors which sit behind TPI plenum. Not the case here - this is a TBI car, but it is the same part! There is very little air movement back there and I can only guess how hot it gets there. I have a lab scope, but dragging all this equipment out is a bit problematic. Simpler and quicker (and less scientific I admit) is to swap ICM and see if the stumble goes away.

5) MAP sensor that I swapped in was calibrated against vacuum gauge on a test bench. Here is the response curve for this MAP (Plot shows response curves for two different MAP sensors, one of the two was used for verify installed on the car)

My suspicions about 89 Camaro ills :

a) There is uncontrollable extra fuel getting into the engine - possibly leaky fuel injector or a crack in the injector pod.

b) Flaky ICM - once its get hot occasional DRP pulse drop out become persistent and periodic.

Actions going forward - need to review hot data log (been very busy)

//RF

2) After warm up period (~2 min of run time) reported BLM clicks down from 128 (open loop warmup) down to 119 counts and stays there. IRC 108 is minimum value for BLM

3) I took a look at #1 plug - it appeared clean enough - slightly rich with hint of oil. As for HV testing - I have several OE coils which can be pressed into swap service if need be.

4) DRP pulse - this is a classic problem. I have seen hot ICM develop intermittent DRP pulse wave forms once they are hot. This is especially true for TPI distributors which sit behind TPI plenum. Not the case here - this is a TBI car, but it is the same part! There is very little air movement back there and I can only guess how hot it gets there. I have a lab scope, but dragging all this equipment out is a bit problematic. Simpler and quicker (and less scientific I admit) is to swap ICM and see if the stumble goes away.

5) MAP sensor that I swapped in was calibrated against vacuum gauge on a test bench. Here is the response curve for this MAP (Plot shows response curves for two different MAP sensors, one of the two was used for verify installed on the car)

My suspicions about 89 Camaro ills :

a) There is uncontrollable extra fuel getting into the engine - possibly leaky fuel injector or a crack in the injector pod.

b) Flaky ICM - once its get hot occasional DRP pulse drop out become persistent and periodic.

Actions going forward - need to review hot data log (been very busy)

//RF

#36

Supreme Member

Re: LO3 Wont stay running.

It's odd that BLM is toggling with O2 voltage. I would expect to see Integrator produce this pattern. In fact I'll assume that it's just a datalog error and that we are actually looking at Integrator. BLM is long term and will change more steadily as it's pushed by integrator in the ECM's effort to keep Integrator toggling around its center of 128. I forget my early GM speak but I believe both INT and BLM limit at 100 low and 156 high but I could be wrong on this. It's based on a multiplier Bla Bla Bla.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

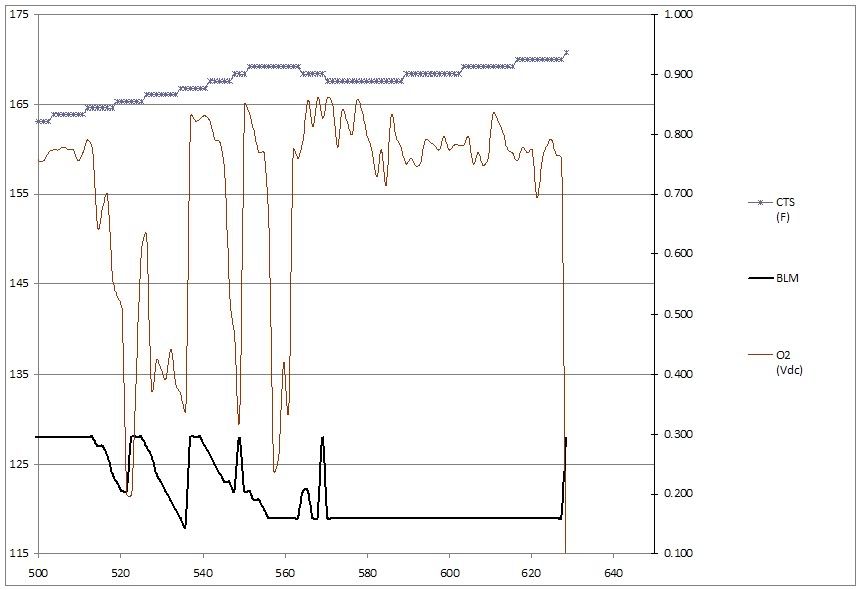

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

#37

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

It's odd that BLM is toggling with O2 voltage. I would expect to see Integrator produce this pattern. In fact I'll assume that it's just a datalog error and that we are actually looking at Integrator. BLM is long term and will change more steadily as it's pushed by integrator in the ECM's effort to keep Integrator toggling around its center of 128. I forget my early GM speak but I believe both INT and BLM limit at 100 low and 156 high but I could be wrong on this. It's based on a multiplier Bla Bla Bla.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

#38

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

It's odd that BLM is toggling with O2 voltage. I would expect to see Integrator produce this pattern. In fact I'll assume that it's just a datalog error and that we are actually looking at Integrator. BLM is long term and will change more steadily as it's pushed by integrator in the ECM's effort to keep Integrator toggling around its center of 128. I forget my early GM speak but I believe both INT and BLM limit at 100 low and 156 high but I could be wrong on this. It's based on a multiplier Bla Bla Bla.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

I understand the pain of setting up a lab scope. We have both the Interro and an old Sun Interrogator. Theyre both a pain. But my old Snap On Vantage is so handy, like using a DVOM. Yet it functions as a scope and even has diagnostic software with connector views and pre-programmed test setups by application. I paid $1,500 for mine used 11 years ago. I bet you could buy the same unit for $300 today. F-ing Snap On. Now that they came out with the Vantage Pro, everyone is dumping their old stuff. Except for me. I'm old and stubborn.

If I assume that the drop off on the second screen is the stall, I can offer this interpretation. I can see that the O2 is toggling before it goes high. I also see Integrator toggle until the O2 goes off and then Int goes low to bring the O2 back. However, the O2 doesn't respond to the change in fuel delivery. I would be wondering right now if the O2 may be faulty. Do you have a known good one that you can substitute? Also, you might try to unplug the O2 and see if the problem goes away with the system stuck in open loop.

Assuming that we are actually seeing Integrator, it would be interesting to watch both Integrator and BLM simultaniously to see BLM change in response to Integrator. This is all internal ECM and in the software, and has little to do with any sensor but just to verify that the system is working correctly. Also, as we watch Integrator, watch injector pulse width to verify that it changes with Integrator. Just some thoughts.

To track INT changes I'll have to bring EBL ECM and load it with LO3 stock calibration to establish a base line. EBL has a high speed interface and allows to captures more than dozen ECM parameter readings per second.

Looking at the first data log (I have not had a chance to look at second) it would appear that BLM rails out at 119 counts. My guess, at idle, this is equates to 1.0 - 1.1 mSec injector pulse width (even though we measured 11 PSI) ECM - stock TBI injectors can not sustain shorter pulse width due to inertia. Again - this can be easily verified with o-scope.

O2 appears to be alive. But I do suspect ignition system having few faults. A misfiring cylinder (or two) would throw raw fuel and unused O2 into exhaust where O2 would be picked up by NBO. ECM would detect extra O2 by adding additional fuel to compensate for extra O2.

During first 300 seconds O2 appears to function normally as it can be seen in the plot below:

//RF

#39

Supreme Member

Re: LO3 Wont stay running.

I am still confused as to why BLM tracks with Integrator, forgiving that your slow data rate may not be accurately representing Integrator changes. When the O2 stops toggling and goes high, Integrator goes neutral and BLM drops low. I would expect to see Integrator follow O2 voltage in a mirror image, while BLM goes high or low of neutral only to keep Integrator toggling. When Integrator goes low, which it should do when O2 goes high, then BLM would go low to pull Int back down. Perhaps it is just your datastream software, but something is not right with the relationship between O2 voltage, Integrator, and BLM.

I would be curious to see datastream from a handheld scan tool, even just to test your communication interface.

I would be curious to see datastream from a handheld scan tool, even just to test your communication interface.

#40

Supreme Member

Join Date: Jan 2007

Location: OC CA

Posts: 1,873

Likes: 0

Received 0 Likes

on

0 Posts

Car: 75 Beast

Engine: 383 +EBL Flash

Transmission: 700R4

Axle/Gears: 4.11 with 33"

Re: LO3 Wont stay running.

I am still confused as to why BLM tracks with Integrator, forgiving that your slow data rate may not be accurately representing Integrator changes. When the O2 stops toggling and goes high, Integrator goes neutral and BLM drops low. I would expect to see Integrator follow O2 voltage in a mirror image, while BLM goes high or low of neutral only to keep Integrator toggling. When Integrator goes low, which it should do when O2 goes high, then BLM would go low to pull Int back down. Perhaps it is just your datastream software, but something is not right with the relationship between O2 voltage, Integrator, and BLM.

I would be curious to see datastream from a handheld scan tool, even just to test your communication interface.

I would be curious to see datastream from a handheld scan tool, even just to test your communication interface.

The 160 baud data stream consists of continuous stream of single data bits. Each bit is made up of a high to low, and a low to high voltage transition within a time of 6.25 mSec. A typical ALDL data packet may contain 20 bytes of data including a sync flag, giving a total of 21 x 9 bits = 189 bits per packet, and a transmission time of 189 x 6250 uSec = 1.18 seconds. The ECU may also insert a short delay between each frame. Clearly at 160 baud (1.18sec) you are not observing 23 out 24 possible values of integrator.

This is why the later P4 PCM's, which sport data rate of about 800 bytes per second (8192 baud), are a great improvement over earlier ECM's.

//RF

#42

Supreme Member

Re: LO3 Wont stay running.

Any new information? It sounds like RF Master is on top of this. I am confused by the ECM data, but I think RF will get to the bottom of it.

#43

Supreme Member

Re: LO3 Wont stay running.

One thing that concerns me is that the O2 goes high and there is no response from INT. BLM goes low but as I said earlier, INT is short term fuel trim and it should be following O2 in a mirror image. Is it possible that the O2 could be cooling off, causing the system to fall out of closed loop, or could the O2 sensor be slow to respond? I would certainly want to look there.

#44

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

One thing that concerns me is that the O2 goes high and there is no response from INT. BLM goes low but as I said earlier, INT is short term fuel trim and it should be following O2 in a mirror image. Is it possible that the O2 could be cooling off, causing the system to fall out of closed loop, or could the O2 sensor be slow to respond? I would certainly want to look there.

Problem still persists.

#45

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

Update- So after changing those parts on tuesday, I had the car towed to an auto shop that my buddy is a service writer at, he offered to diagnose it for free. Today I called him and he told me the distributor is shot. They put a test dizzy in and it solved the problem 100%! I went to the shop when the test dizzy was still in and it held gear and purred at idle/wot. So now I need to buy a new dizzy. Anybody have one laying around?

#46

Senior Member

Thread Starter

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Re: LO3 Wont stay running.

Final Update-- Replaced dizzy today and she runs smooth! Drove it out of the shop and been driving it all day!(30 miles) She runs smooth with all the new parts on it lol Thanks everyone for all the help!

#47

Supreme Member

Re: LO3 Wont stay running.

Lol. It's always the simple things. Good news.

Thread

Thread Starter

Forum

Replies

Last Post