Wooden ramps... Work great!!

#1

Wooden ramps... Work great!!

Hey everybody... I just wanted to show some pics of the wooden ramps that I built. There isnt a "Tools" section, and since I fabricated these, I figured this was the best place. I got the idea from this website:

http://www.mustangworld.com/ourpics/...amps/index.htm

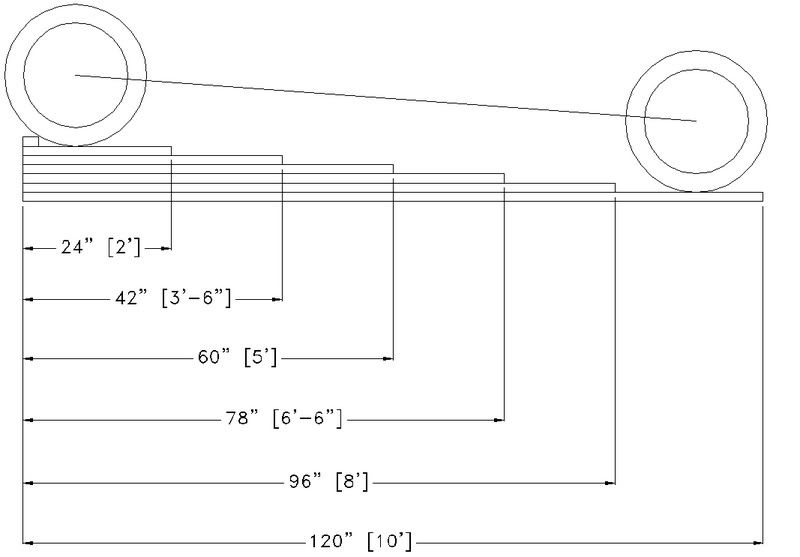

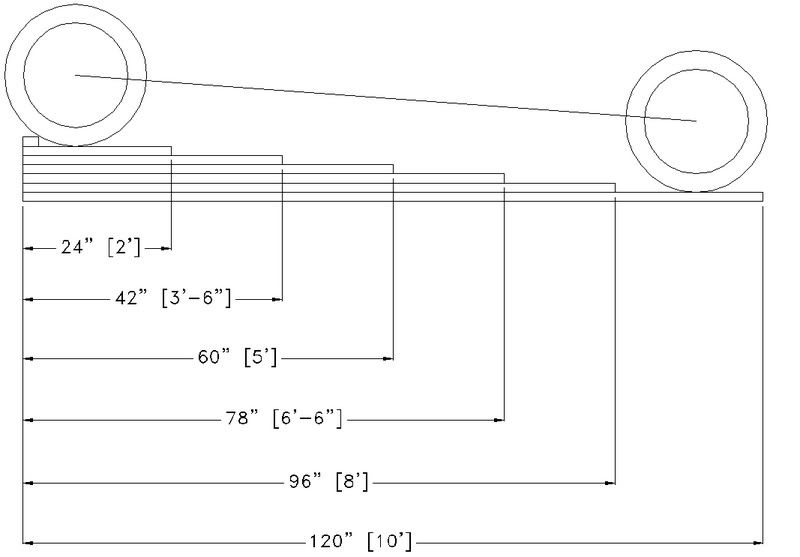

That jump started me on my quest to build them. I really hated trying to use a jack to get my car in the air. And ryhino ramps just dont cut it anymore. My car is lowered, and with the lightened flywheel, spec cluch, and alittle bit of cam lope...they are really difficult to get up. These are just like going up a hill. I used autocad, and my wheelbase to figure out how to make them just right. I made them taller than the ones on the mustang website.

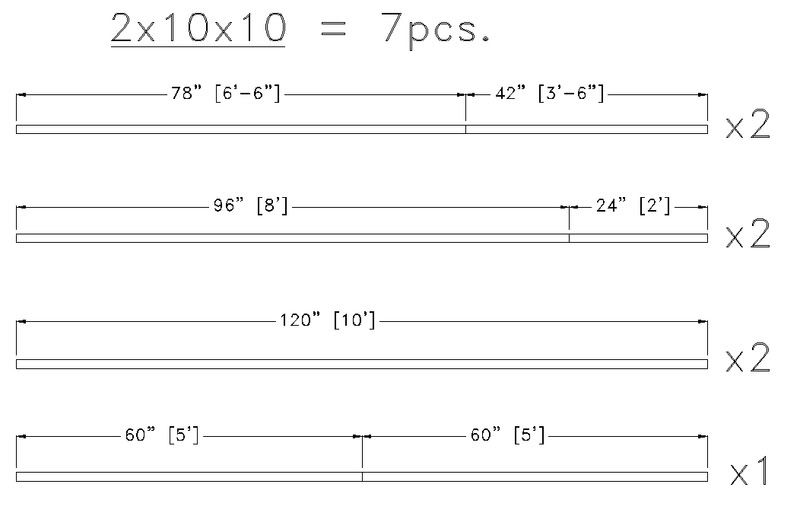

If you make them like I did...they are HEAVY. Thats their only drawback. Im going to install handles to make them easier to pull around. If you make them my way, you will be able to build them out of 7 pieces of 2x10 lumber, at 10 feet long. You wont have any scrap left over. I wanted my rear tires to come up on the ramps some for two reasons. One, when I feel the rear tires come up, I know Im on the top level and I need to feel for the wheel stop. Two, So that it gave me some more space in the back to get the jack under the car.

Anyway, on to the pictures. If anyone has any questions, feel free to ask. Im sure Im not the only one who has made these...but I just wanted to show that I had good results. Anyone wanting the measurments that I used, let me know, and Ill post up a diagram.

Justin

P.S. Im working on a system to space the ramps properly, instead of using my eye. I wasnt centered perfectly on the ramps at all... I also wanted to mention, they feel very stable and when the car is up there, it seems rock solid. While pulling up on the ramps, their weight helps keep them from sliding. They never budge.

Just a shot showing how the jack can easily be used on the rear to get it up in the air too.

http://www.mustangworld.com/ourpics/...amps/index.htm

That jump started me on my quest to build them. I really hated trying to use a jack to get my car in the air. And ryhino ramps just dont cut it anymore. My car is lowered, and with the lightened flywheel, spec cluch, and alittle bit of cam lope...they are really difficult to get up. These are just like going up a hill. I used autocad, and my wheelbase to figure out how to make them just right. I made them taller than the ones on the mustang website.

If you make them like I did...they are HEAVY. Thats their only drawback. Im going to install handles to make them easier to pull around. If you make them my way, you will be able to build them out of 7 pieces of 2x10 lumber, at 10 feet long. You wont have any scrap left over. I wanted my rear tires to come up on the ramps some for two reasons. One, when I feel the rear tires come up, I know Im on the top level and I need to feel for the wheel stop. Two, So that it gave me some more space in the back to get the jack under the car.

Anyway, on to the pictures. If anyone has any questions, feel free to ask. Im sure Im not the only one who has made these...but I just wanted to show that I had good results. Anyone wanting the measurments that I used, let me know, and Ill post up a diagram.

Justin

P.S. Im working on a system to space the ramps properly, instead of using my eye. I wasnt centered perfectly on the ramps at all... I also wanted to mention, they feel very stable and when the car is up there, it seems rock solid. While pulling up on the ramps, their weight helps keep them from sliding. They never budge.

Just a shot showing how the jack can easily be used on the rear to get it up in the air too.

#2

Supreme Member

iTrader: (1)

Join Date: Dec 2004

Location: Arcadia ,Ca

Posts: 2,492

Likes: 0

Received 0 Likes

on

0 Posts

Car: 82 firebird s/e 83 Trans Am

Engine: 5.0L 305ci 4b carb.....CFI

Transmission: TH200C....700R4

Re: Wooden ramps... Work great!!

Perfect,they match your screen name lol

j/k as long as the car doesnt fall on you,they are cool

j/k as long as the car doesnt fall on you,they are cool

#3

Re: Wooden ramps... Work great!!

Haha... Trust me. These are far from ghetto. There is no more a chance of the car falling using these than when using a jack or rhino ramps.

They use pieces of lumber like this to jack up houses when they move them. And the width gives plenty of stability.

I trust these WAY more than I trust any of the ramps that I gotten in the past...rhino ramps included.

When pulling up to them, and onto them, they dont budge. Their weight, and large contact area with the driveway keeps them in place when you start driving up on them. They wont push like the other ramps do. And, if I dont want to go all the way up...I dont have to. I can stop short of the top landing if I just wanna get under tochange oil or something.

I planned to put support feet on the bottoms if I felt they were unstable. But they are rock solid with the car on them.

Justin

P.S. I will mention that I dont think Ide do anything major with them on these ramps. Just like I wouldnt do anything major while on rhino ramps. I made these as an aid for getting the car up in the air. While on the ramps, I can easily use a jack, take the car up an inch on both sides and put jackstands under it. It just makes it easier. You dont have to go alittle at a time on both sides to get stands under it. Plus, for doing oil changes or greasing steering or things of that nature, its a snap to drive up these, do the work, then back down. No fuss...

They use pieces of lumber like this to jack up houses when they move them. And the width gives plenty of stability.

I trust these WAY more than I trust any of the ramps that I gotten in the past...rhino ramps included.

When pulling up to them, and onto them, they dont budge. Their weight, and large contact area with the driveway keeps them in place when you start driving up on them. They wont push like the other ramps do. And, if I dont want to go all the way up...I dont have to. I can stop short of the top landing if I just wanna get under tochange oil or something.

I planned to put support feet on the bottoms if I felt they were unstable. But they are rock solid with the car on them.

Justin

P.S. I will mention that I dont think Ide do anything major with them on these ramps. Just like I wouldnt do anything major while on rhino ramps. I made these as an aid for getting the car up in the air. While on the ramps, I can easily use a jack, take the car up an inch on both sides and put jackstands under it. It just makes it easier. You dont have to go alittle at a time on both sides to get stands under it. Plus, for doing oil changes or greasing steering or things of that nature, its a snap to drive up these, do the work, then back down. No fuss...

#4

Supreme Member

iTrader: (1)

Join Date: Dec 2004

Location: Arcadia ,Ca

Posts: 2,492

Likes: 0

Received 0 Likes

on

0 Posts

Car: 82 firebird s/e 83 Trans Am

Engine: 5.0L 305ci 4b carb.....CFI

Transmission: TH200C....700R4

Re: Wooden ramps... Work great!!

Do you have any other plans for them ,like painting them.And then stick a craftsman sticker on it.Theyll look factory.

#5

Banned

iTrader: (12)

Join Date: Jul 1999

Location: Bertram (outside Austin), TX

Posts: 12,212

Likes: 0

Received 10 Likes

on

10 Posts

Car: 87 GTA

Engine: L98

Transmission: 700R4

Axle/Gears: Dana M78 3.27 posi

Re: Wooden ramps... Work great!!

I did the same thing years ago for my lowered 92 RS. The difference was, mine were only for the front tires, not full length. 1 2"x10",per side. And I screwed those yellow hooks you can buy frome Home Depot/Lowe's into the end, as handles, and to hang them up in my garage.

I did the same thing years ago for my lowered 92 RS. The difference was, mine were only for the front tires, not full length. 1 2"x10",per side. And I screwed those yellow hooks you can buy frome Home Depot/Lowe's into the end, as handles, and to hang them up in my garage.I gave them away a few months back though. I might build another set some day. Who knows. I just couldn't use them now anyways, so I gave them to a friend that has helped me a lot over the past year.

#6

Re: Wooden ramps... Work great!!

Some people might laugh at them, but I'm not laughing. I have wood ramps that are at least 15 years old. Mine are much shorter, and not nearly as heavy. I have three vehicles that are low enough that I cannot fit a jack under them without using something like this first.

As far as strength, those that you built should easily hold up a D8 Cat dozer.

As far as strength, those that you built should easily hold up a D8 Cat dozer.

#7

Re: Wooden ramps... Work great!!

Vader those look pretty cool! I thought about making a short set, just for doing oil changes. And leave the big set for doing other jobs. But I just got tired of smaller ramps pushing away when my tires hit them. So I just built the bit set for now. I need to start working out anyway haha... So hauling these around is a good start!

Plus, this wood was a fresh load from Lowes...its VERY wet. Im going to leave them out in the sun to dry out, and they should lighten up a bit. Still gnona be heavy...

As for finishing them off some way, they are pressure treated so they should be ok for awhile. If they start to take a hit from being outside all the time, I might use some left over deck/porch sealer on them. We use that stuff on our pool deck and at 15 years old, most of the boards are still flat and solid like the day we built it.

Justin

Plus, this wood was a fresh load from Lowes...its VERY wet. Im going to leave them out in the sun to dry out, and they should lighten up a bit. Still gnona be heavy...

As for finishing them off some way, they are pressure treated so they should be ok for awhile. If they start to take a hit from being outside all the time, I might use some left over deck/porch sealer on them. We use that stuff on our pool deck and at 15 years old, most of the boards are still flat and solid like the day we built it.

Justin

Trending Topics

#8

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,041

Received 1,668 Likes

on

1,266 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: Wooden ramps... Work great!!

So... have you compared the cost of all that wood, to a set of Rhino ramps?

Last edited by sofakingdom; 03-26-2007 at 08:35 AM.

#9

Re: Wooden ramps... Work great!!

Have you ever tried to drive a lowered 3rd gen, with a lightweight flywheel'd LS1, with cam lope and a spec clutch up a set of ramps??? Its not fun. My nose hits the rhino's and pushes them. If I use wood to get up to the ramps, my tires usually squeeze the ramps out of one side on the way up. To get the car to creep like that, it takes quite a bit of revs due to the flywheel. Plus, just to keep the "if you know how to drive its easy" comments to a minimum, I will say that Im still fairly new to driving this car. I have 2000 miles on my swap, and this is the first stick car Ive owned. Im good...but trying to go up rhino ramps makes me nervous, and its a pain like I said.

I only have $75 into these ramps by the way...

Whats a set of rhinos... $20 - $30?? Worth it in my opinion. Mine are easier to drive on, go alittle higher, will never crush or fail, and dont sink into my driveway when I let the car sit on them for awhile.

Whats a set of rhinos... $20 - $30?? Worth it in my opinion. Mine are easier to drive on, go alittle higher, will never crush or fail, and dont sink into my driveway when I let the car sit on them for awhile. Justin

#10

Junior Member

Join Date: Feb 2005

Location: Australia

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1990 IROC-Z Coupe

Engine: 383

Transmission: T56

Re: Wooden ramps... Work great!!

Awesome! I am going to make some of these. I have the same problems with my IROC. My only question is; do you think it would be a good idea to get another long plank (tad longer than the bottom one) and nail it to the top, so you have a smooth run up to the last level? Perhaps the added weight is not worth it, but if thats not really a problem I reckon it would be a good improvement. What you think?

#11

Banned

iTrader: (12)

Join Date: Jul 1999

Location: Bertram (outside Austin), TX

Posts: 12,212

Likes: 0

Received 10 Likes

on

10 Posts

Car: 87 GTA

Engine: L98

Transmission: 700R4

Axle/Gears: Dana M78 3.27 posi

Re: Wooden ramps... Work great!!

If you are referring to a smooth ramp, no. The stepped version is better. You only go up 2" at a time, then you are flat again. 2" step..flat...over & over.

I cut the drive on ends at 45 degree angles, rather than straight across for 90 degrees. It makes the transition from step to step, that much easier. With everything built correctly, I could incorporate a built-in stop, rather than a simple 2"x2" block on top.

I cut the drive on ends at 45 degree angles, rather than straight across for 90 degrees. It makes the transition from step to step, that much easier. With everything built correctly, I could incorporate a built-in stop, rather than a simple 2"x2" block on top.

#12

Member

iTrader: (1)

Join Date: Jan 2005

Location: willow grove, PA

Posts: 317

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1992 Camaro vert

Engine: 355

Transmission: 700r4

Axle/Gears: 10 bolt... not blow up yet

Re: Wooden ramps... Work great!!

well i have a garage that i park my car in and work on it and i think this would be great as a three piece unit... like the two sides and measure the width of ur car and put another piece connecting them and then put another 2x10 on the far left and far right as a channel to ensure that u wont fall off it... then when ur done you can just unhook the connecting piece and hang it on the wall with the ramps... idk just an idea

#13

Senior Member

Join Date: Jan 2006

Location: League City, TX

Posts: 720

Likes: 0

Received 1 Like

on

1 Post

Car: 90 Formula -- tot resto in progress

Engine: 350

Transmission: 700R4 w/ 2500 stall, by Owen @ ARD

Axle/Gears: 3.23 posi disc

Re: Wooden ramps... Work great!!

If you have a power saw, tilt the blade to make an angle cut

on each layer, which will make drive-on a bit easier.

I used treated 2x6's, with a chunk of 4x4 for the top-layer

stop. 4 layers, about 6' long are sufficient for me. Leave

em outside with no worry.

on each layer, which will make drive-on a bit easier.

I used treated 2x6's, with a chunk of 4x4 for the top-layer

stop. 4 layers, about 6' long are sufficient for me. Leave

em outside with no worry.

#14

Supreme Member

Join Date: Sep 2005

Location: Ottawa, ONT

Posts: 1,951

Likes: 0

Received 7 Likes

on

7 Posts

Car: 1987 Firebird

Engine: 355

Transmission: T56

Re: Wooden ramps... Work great!!

Youre probably using these inside, my only worry is, what if the wood gets wet? It'll be pretty slippery. Also, sometimes the rear will be in a lil bump in the road of something, so the jack will stay still, meaning the car will wanna roll forward when jacked up. Any issues with that?

Obvioulsy im thinking of building something like this for "off road" use. But i LOVE the idea.

Obvioulsy im thinking of building something like this for "off road" use. But i LOVE the idea.

#15

Banned

iTrader: (12)

Join Date: Jul 1999

Location: Bertram (outside Austin), TX

Posts: 12,212

Likes: 0

Received 10 Likes

on

10 Posts

Car: 87 GTA

Engine: L98

Transmission: 700R4

Axle/Gears: Dana M78 3.27 posi

Re: Wooden ramps... Work great!!

Youre probably using these inside, my only worry is, what if the wood gets wet? It'll be pretty slippery. Also, sometimes the rear will be in a lil bump in the road of something, so the jack will stay still, meaning the car will wanna roll forward when jacked up. Any issues with that?

Obvioulsy im thinking of building something like this for "off road" use. But i LOVE the idea.

Obvioulsy im thinking of building something like this for "off road" use. But i LOVE the idea.

As far as bumps in the road. What are you going to do? Tote these around? No. They will be used in a driveway or garage...flat concrete.

#16

Supreme Member

Join Date: Sep 2005

Location: Ottawa, ONT

Posts: 1,951

Likes: 0

Received 7 Likes

on

7 Posts

Car: 1987 Firebird

Engine: 355

Transmission: T56

Re: Wooden ramps... Work great!!

Well obvioulsy they wont fall over, but if the wood is slippery, its hard to drive onto. Notice how U-haul trailiers have little dimples for that reason?

Also, the use i have planned is, flat yes, concrete no... Hence the "offroad". As well, not everyone's driveway is flat, even though it may be paved, wear and tear causes little bumps and valleys over time.

I realize this isnt patented technology and its something a guy at home can do, but still, id like to find out what he has in mind if those situations are encountered.

Also, the use i have planned is, flat yes, concrete no... Hence the "offroad". As well, not everyone's driveway is flat, even though it may be paved, wear and tear causes little bumps and valleys over time.

I realize this isnt patented technology and its something a guy at home can do, but still, id like to find out what he has in mind if those situations are encountered.

#17

Banned

iTrader: (12)

Join Date: Jul 1999

Location: Bertram (outside Austin), TX

Posts: 12,212

Likes: 0

Received 10 Likes

on

10 Posts

Car: 87 GTA

Engine: L98

Transmission: 700R4

Axle/Gears: Dana M78 3.27 posi

Re: Wooden ramps... Work great!!

No, not all driveways are perfectly flat. But, the dimples and such should,'t create any problems. If you have holes that woul, you've got bigger fish to fry.

I never had any problems with my wooden ones. For dimples, I guess you could use a sawzall, to cut 1/8" grooves sideways across the ramps. Or, just use a BFH to create dimples in the wood, but even then, the dimples might be kinda smooth textures. Maybe a 1/2" drill bit to create "dimple" holes, partialy through?

I just know I never had a problem with mine, over YEARS of use.

I never had any problems with my wooden ones. For dimples, I guess you could use a sawzall, to cut 1/8" grooves sideways across the ramps. Or, just use a BFH to create dimples in the wood, but even then, the dimples might be kinda smooth textures. Maybe a 1/2" drill bit to create "dimple" holes, partialy through?

I just know I never had a problem with mine, over YEARS of use.

Last edited by Stephen; 03-27-2007 at 05:56 PM.

#18

Re: Wooden ramps... Work great!!

Sorry guys...didnt realize there were new posts.

To answer a couple questions/comments. I thought about cutting angles on the front of the boards. But I wanted it to be alittle difficult to bump over to the next level. One it keeps me in control alittle easier, and two I can definetly feel each level. The boards are only 1.5" tall, and my car rolls up onto each level very easy. I had a 97 LT1 car up on them today and it was cake. Even easier with his because he is stock. Like I said, my lightweight flywheel produces a challenge.

Definetly dont make them smooth with a nother board. Your car will constantly want to roll down the ramp. The steps are there to keep the car on that particular level of the ramp, and reduce the risk of it rolling backwards on you.

If its raining, it might be a little slippery...but not enough to keep you from going up them. Its only a little step, not a steep smooth incline. Your back tires dont touch the ramp til the last step, and just alittle bump gets you over them. These will only be used outside...atleast for me. i dont have enough room in my garage to work on my TA. That car is longer than it looks! I have to back it up to the work bench and even then the door only has about a foot of clearance.

online170: I know what you are saying about the "bump in the road" and using the jack. The car will not want to go forward, it will want to go backwards. As the jack rises, the lift pad pulls backwards. I usually deal with this by pumping, then give the handle a wiggle, pump, wiggle, pump, etc. Its usually enough to get the jack out of the divets that it just created in the driveway. Also, the wheel chocks that I have for the rear of the tires are heavy dense rubber. The car resists being pulled backwards really well. Also, I have a piece of sheet steel...I think its 1/8" thick. I welded steel handles to it, so its easier to pick up when its laying flat against the driveway/garage floor. I use that under the jack, giving it a smoother surface, so the wheels can easily roll and allow the body of the jack to stay under the lift pad.

Stephen: What did you have in mind for a built in step? Today while I was installing handles on the ramps to make moving them easier, I put another piece of 2x3 on top. So now I have a 3" x 2.5" stop instead of a 1.5" x 2.5" stop. The car wont roll over that easy, and you can really tell when you are against it. But Im curious about your idea of a built in stop...Im always looking for ways to improve what Ive done...

Im glad this turned into a good discussion and not a making fun of wooden ramps thread! I really think these things can be useful to the weekend mechanic. Or atleast a variation of these. My buddy and I had his LT1 up on the ramps in a matter of minutes, and were able to roll all the way under the car. Much better than rhino's or jacks....

Justin

To answer a couple questions/comments. I thought about cutting angles on the front of the boards. But I wanted it to be alittle difficult to bump over to the next level. One it keeps me in control alittle easier, and two I can definetly feel each level. The boards are only 1.5" tall, and my car rolls up onto each level very easy. I had a 97 LT1 car up on them today and it was cake. Even easier with his because he is stock. Like I said, my lightweight flywheel produces a challenge.

Definetly dont make them smooth with a nother board. Your car will constantly want to roll down the ramp. The steps are there to keep the car on that particular level of the ramp, and reduce the risk of it rolling backwards on you.

If its raining, it might be a little slippery...but not enough to keep you from going up them. Its only a little step, not a steep smooth incline. Your back tires dont touch the ramp til the last step, and just alittle bump gets you over them. These will only be used outside...atleast for me. i dont have enough room in my garage to work on my TA. That car is longer than it looks! I have to back it up to the work bench and even then the door only has about a foot of clearance.

online170: I know what you are saying about the "bump in the road" and using the jack. The car will not want to go forward, it will want to go backwards. As the jack rises, the lift pad pulls backwards. I usually deal with this by pumping, then give the handle a wiggle, pump, wiggle, pump, etc. Its usually enough to get the jack out of the divets that it just created in the driveway. Also, the wheel chocks that I have for the rear of the tires are heavy dense rubber. The car resists being pulled backwards really well. Also, I have a piece of sheet steel...I think its 1/8" thick. I welded steel handles to it, so its easier to pick up when its laying flat against the driveway/garage floor. I use that under the jack, giving it a smoother surface, so the wheels can easily roll and allow the body of the jack to stay under the lift pad.

Stephen: What did you have in mind for a built in step? Today while I was installing handles on the ramps to make moving them easier, I put another piece of 2x3 on top. So now I have a 3" x 2.5" stop instead of a 1.5" x 2.5" stop. The car wont roll over that easy, and you can really tell when you are against it. But Im curious about your idea of a built in stop...Im always looking for ways to improve what Ive done...

Im glad this turned into a good discussion and not a making fun of wooden ramps thread! I really think these things can be useful to the weekend mechanic. Or atleast a variation of these. My buddy and I had his LT1 up on the ramps in a matter of minutes, and were able to roll all the way under the car. Much better than rhino's or jacks....

Justin

#20

Member

Join Date: Jul 2005

Location: The Gem State

Posts: 270

Likes: 0

Received 0 Likes

on

0 Posts

Car: 82 Firebird, 71 LeMans

Engine: GMPP 350, 400 PMD

Transmission: TH-350

Re: Wooden ramps... Work great!!

I vote sticky for this great innovative idea! Good job ghettocruiser!

#23

Re: Wooden ramps... Work great!!

Haha I dont know if its sticky worthy. But thanks for the props guys! Like I said, I got the idea from the other site and ran with it. I just never saw anyone elses home made before....

Stephen: Hmmm...I like it. Gives you alittle more room on the upper landing as well. Although its too late to do that to mine without surgery. I had the LT1 guy bump my stops pretty good, and they didnt even budge. So they will work for now. I had to nail mine in...due to the screws always splitting the 2x3, and I wasnt about to waste time finding a drill bit and making pilot holes. haha. So I did it with good old hammer and nails. They seem to be nice and solid. Good idea!!! (edit: actually I just thought about that. I could still screw a vertical piece to the end of my ramps. Its pretty level in back so it should work... )

I really want to come up with a system for getting these lined up and spaced correctly for the vehicle going up them. Im still thinking some temporary cross braces to get the spacing correct, and keep them parallel and in line with each other. something that can be takin out from under the car to roll under or get the jack under... Might be as simple as just cutting some wood to length and laying it between the ramps to get it started... My car will be going up on these tonight, and staying on them for awhile, so Ill figure it out. Ill also post on how well the rasing the rear end part goes....

J.

Stephen: Hmmm...I like it. Gives you alittle more room on the upper landing as well. Although its too late to do that to mine without surgery. I had the LT1 guy bump my stops pretty good, and they didnt even budge. So they will work for now. I had to nail mine in...due to the screws always splitting the 2x3, and I wasnt about to waste time finding a drill bit and making pilot holes. haha. So I did it with good old hammer and nails. They seem to be nice and solid. Good idea!!! (edit: actually I just thought about that. I could still screw a vertical piece to the end of my ramps. Its pretty level in back so it should work... )

I really want to come up with a system for getting these lined up and spaced correctly for the vehicle going up them. Im still thinking some temporary cross braces to get the spacing correct, and keep them parallel and in line with each other. something that can be takin out from under the car to roll under or get the jack under... Might be as simple as just cutting some wood to length and laying it between the ramps to get it started... My car will be going up on these tonight, and staying on them for awhile, so Ill figure it out. Ill also post on how well the rasing the rear end part goes....

J.

#24

Re: Wooden ramps... Work great!!

Hey guys. I said I post some pics after I used a jack to bring the rear of the car up... SO here they are. Also, I came up with an idea for helping to keep the car from rolling. I used ratchet straps as you can see. Those handles are screwed into the wood with 2.5" screws...so they arent going anywhere. I know it looks kinda ghetto, but I just wanted to try it out. Actually...with only the straps, no wheel chocks, I had my dad sit in the car with it in neutral and the ebrake off. I couldnt roll the car backwards on my own. The straps seem to work. I still used wheel chocks of course when lifting the rear... but the front never moved.

The strap...same on both sides. The piece of wood is to keep the ratchet mechanism off my wheels.

Here it is with the back up. No drama, just went right up. Plenty of room for the jackstands to be put on the axle.

Just a shot showing how the wheels never rolled back.

Just a shot or two of the room under the car now...

I was happy. Still wish the car was alittle higher. Its not as bad without the creeper, but its harder to slide under. But...they will work great for what I want to do. Plenty of space for exhaust and what not.

Justin

The strap...same on both sides. The piece of wood is to keep the ratchet mechanism off my wheels.

Here it is with the back up. No drama, just went right up. Plenty of room for the jackstands to be put on the axle.

Just a shot showing how the wheels never rolled back.

Just a shot or two of the room under the car now...

I was happy. Still wish the car was alittle higher. Its not as bad without the creeper, but its harder to slide under. But...they will work great for what I want to do. Plenty of space for exhaust and what not.

Justin

#25

Supreme Member

Join Date: Sep 2005

Location: Ottawa, ONT

Posts: 1,951

Likes: 0

Received 7 Likes

on

7 Posts

Car: 1987 Firebird

Engine: 355

Transmission: T56

Re: Wooden ramps... Work great!!

Cool, thanks for the answers ghetto, ur right it does roll BACK, im a bit paranoid cuz i had a car fall down on me (not literally, i wasnt beneath the car), but it wasnt a nice experience. Luckily it was a parts car, and no one was hurt. Also, i didnt notice the rubber chocks you had under there, and those straps will definately keep the wheels from rolling.

My buddy and i are working on building a pair. The last question i have for you is, you said you used autocad to aid you in calculating the distance of the steps? How did you do that? I have access to autocad, but id like to know what exactly you measured. We are thiking of building it for a lowere 73 mustang with subframe connectors.

My buddy and i are working on building a pair. The last question i have for you is, you said you used autocad to aid you in calculating the distance of the steps? How did you do that? I have access to autocad, but id like to know what exactly you measured. We are thiking of building it for a lowere 73 mustang with subframe connectors.

#26

Re: Wooden ramps... Work great!!

I think it would be cool to somehow make the highest "level" removable.

I say this because I think it would be cool to be able to drive the car up on ramps that long, then remove the actual ramped part and leave it up on what are essentially jackstands under hte tires. I dont think it would be dangerous at all if you've got the wheels chocked and those straps... The hard part would be figuring out a way to lock the two pieces together when driving onto them.

In the end, I suppose it's just slightly unnecessary and too much work, but all I can think of is how LONG LONG ramps would be awesomely convenient... UNTIL you need to get under the car...

I say this because I think it would be cool to be able to drive the car up on ramps that long, then remove the actual ramped part and leave it up on what are essentially jackstands under hte tires. I dont think it would be dangerous at all if you've got the wheels chocked and those straps... The hard part would be figuring out a way to lock the two pieces together when driving onto them.

In the end, I suppose it's just slightly unnecessary and too much work, but all I can think of is how LONG LONG ramps would be awesomely convenient... UNTIL you need to get under the car...

#27

Re: Wooden ramps... Work great!!

online: Ive had a car fall too. One side anyway... And it was due to a rhino ramp failing... Long story. Anyway...when I said I used autocad to design them...it was just simply a way to do it and get the measurements easily. I knew my wheelbase was ~101" . I wanted my ramps higher than the guy on the mustang website, so I knew I needed two more levels. I wanted to keep the 18" landings, and the 24" top level...so that meant I needed to use a 10' bottom piece. The rest I just kind of used cad to lay it out.

If you want my measurements, I can just list them out for ya...or I can probably post my drawing/diagram for the pieces. Mustang wheel base is probably pretty close to the f-body...so they will probably work.

The straps worked great!!! I was thinking it was a dumb idea, til I put tension on the straps and noticed it pulled the tire up against the wheel stop alittle tighter. Then I knew it was gonna work atleast half decent as a back up safety.

InfernalVortex: The beauty of having the long ramps, is if for some reason the wheel chock fails or slips, and the strap breaks, the car will roll backwards, drop off the 1.5" ledge, and probably stop. Instead of like a rhino ramp, where if it drifts back, its going to start down the ramp fast.

I know what you mean about getting under the car, but honestly its not that bad. The car is high enough so that I can roll front to back without getting snagged on anything. Im sure there will be times i wish I could slide in from the side, but Ill deal.

ALSO...I made these ramps mainly to AID in getting the car up... So now that the rear is on jack stands, and the front end is at a good height, you can easily jack up the front corners an inch or so, and use jack stands. Easier than jacking the car up to jackstand height from the ground...atleast in my opinion. Then slide the ramps out...slide em back under when your done. Havent tried this yet...but I might to do some work on my steering stops.

Justin

If you want my measurements, I can just list them out for ya...or I can probably post my drawing/diagram for the pieces. Mustang wheel base is probably pretty close to the f-body...so they will probably work.

The straps worked great!!! I was thinking it was a dumb idea, til I put tension on the straps and noticed it pulled the tire up against the wheel stop alittle tighter. Then I knew it was gonna work atleast half decent as a back up safety.

InfernalVortex: The beauty of having the long ramps, is if for some reason the wheel chock fails or slips, and the strap breaks, the car will roll backwards, drop off the 1.5" ledge, and probably stop. Instead of like a rhino ramp, where if it drifts back, its going to start down the ramp fast.

I know what you mean about getting under the car, but honestly its not that bad. The car is high enough so that I can roll front to back without getting snagged on anything. Im sure there will be times i wish I could slide in from the side, but Ill deal.

ALSO...I made these ramps mainly to AID in getting the car up... So now that the rear is on jack stands, and the front end is at a good height, you can easily jack up the front corners an inch or so, and use jack stands. Easier than jacking the car up to jackstand height from the ground...atleast in my opinion. Then slide the ramps out...slide em back under when your done. Havent tried this yet...but I might to do some work on my steering stops.

Justin

#28

Member

Join Date: Feb 2007

Location: port jefferson station, new york

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 2.8 RS

Engine: the 2.8

Transmission: 700r4 auto

Axle/Gears: stock one wheel squealer

Re: Wooden ramps... Work great!!

online if your worried about the wood getting very slick you can go to any local skate shop and pick up some grip tape for skate boards. its the same as if you were to super glue some coarse sand paper down. its fine in the rain and wont come off easily. also the stuff is rather inexpensive and can be bought by the roll or you can ask them for a certain length. some shops might not sell too many lengths off it but you can get it at an online skate store.

#30

Supreme Member

Join Date: Sep 2005

Location: Ottawa, ONT

Posts: 1,951

Likes: 0

Received 7 Likes

on

7 Posts

Car: 1987 Firebird

Engine: 355

Transmission: T56

Re: Wooden ramps... Work great!!

Striped1, thats an amazing idea, i never would have thought to use that stuff! I guess similarly, if you have any old "roof shingles" lying around, (like i do), it would serve the same purpose.

#31

Member

iTrader: (3)

Join Date: Sep 2006

Location: Forest Grove Oregon

Posts: 130

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1989 Camaro RS, 355, holley 650dp

Engine: flow master headers, 3" exhaust

Transmission: 700r4

Axle/Gears: stock

Re: Wooden ramps... Work great!!

I must admit this is a great idea for changing oil and such...as far as placementwhy not take a small dab of paint and put a dot on 5 sides, front, R front, L front R rear and L rear on the ground then all you'd need to do is line up the ramps same place every time...gonna have to bulid a set.

#32

Re: Wooden ramps... Work great!!

kenf729: Thats a great idea for lining them up! Just mark out the corners... Only problem is, I dont always work on my car in the same spot. But...I like that idea. Lining up to the front tires is easy. Just push the ramp ends up to the tires. If you measure across the boards at the tires, and make the upper end match, they should be close to parallel. That part is pretty easy.

Its just making sure that when you drive straight ahead, you car is going straight in relation to the ramps. Nice thing is, you can do a certain amount of steering on the way up. I usually have someone give me a spot. And they will say alittle left or a little right. And I end up being dead on at the end.

This darn cold weather and not being able to locate the materials I want is slowing me up... SO I havent messed with jacking up the front end with the ramps under yet. Still want to try that.

Some good ideas guys! I like the skateboard no-slip tape idea. If I had inclines on the ramps, Ide be doing just that.

Justin

Its just making sure that when you drive straight ahead, you car is going straight in relation to the ramps. Nice thing is, you can do a certain amount of steering on the way up. I usually have someone give me a spot. And they will say alittle left or a little right. And I end up being dead on at the end.

This darn cold weather and not being able to locate the materials I want is slowing me up... SO I havent messed with jacking up the front end with the ramps under yet. Still want to try that.

Some good ideas guys! I like the skateboard no-slip tape idea. If I had inclines on the ramps, Ide be doing just that.

Justin

#34

Re: Wooden ramps... Work great!!

I think it would be cool to somehow make the highest "level" removable.

I say this because I think it would be cool to be able to drive the car up on ramps that long, then remove the actual ramped part and leave it up on what are essentially jackstands under hte tires. I dont think it would be dangerous at all if you've got the wheels chocked and those straps... The hard part would be figuring out a way to lock the two pieces together when driving onto them.

In the end, I suppose it's just slightly unnecessary and too much work, but all I can think of is how LONG LONG ramps would be awesomely convenient... UNTIL you need to get under the car...

I say this because I think it would be cool to be able to drive the car up on ramps that long, then remove the actual ramped part and leave it up on what are essentially jackstands under hte tires. I dont think it would be dangerous at all if you've got the wheels chocked and those straps... The hard part would be figuring out a way to lock the two pieces together when driving onto them.

In the end, I suppose it's just slightly unnecessary and too much work, but all I can think of is how LONG LONG ramps would be awesomely convenient... UNTIL you need to get under the car...

#35

Re: Wooden ramps... Work great!!

To get the two parts to stay together could be done with door hinges (for a door in your house). Put the two pieces together and screw the hinges in with one side of the hinge in each part. When you want to remove the section, just pull the hinge pins out untill you are finished. Then put the pins back in to lower the car.

that really is a decent solution. I might actually try to figure out how to cut mine and try this... Atleast to one side. Because rolling under from the front or back is getting alittle old. It would be nice to slide in from the side. That would make things like removing the trans easy...so you can just roll out through the side. i just have to figure out how to cut through all those boards. I guess i could unscrew them, take them apart, cut them, then just screw them back together. Already have screw holes so they will be easy to reassemble in the same position.

If my idea for putting the front on jack stands doesnt work out, Ill probably give this a go... If my idea does work out, it will be easy to get the front end up alittle bit for a jack stand, then just slide the whole ramp out of the way. We'll see as soon as the weather here in PA gets more tolerable!!

Justin

#36

Supreme Member

iTrader: (17)

Join Date: Feb 2003

Location: Buckley AFB, CO / Crestview, FL

Posts: 2,182

Likes: 0

Received 0 Likes

on

0 Posts

Car: 83 Z-28

Engine: LG4

Transmission: 700R4

Axle/Gears: 02 WS6 Rear w/3:42

Re: Wooden ramps... Work great!!

Very creative, love the idea. I would build some if I had the space to store them.

#37

Re: Wooden ramps... Work great!!

...P.S. Im working on a system to space the ramps properly, instead of using my eye. I wasnt centered perfectly on the ramps at all... I also wanted to mention, they feel very stable and when the car is up there, it seems rock solid. While pulling up on the ramps, their weight helps keep them from sliding. They never budge.

#38

Re: Wooden ramps... Work great!!

I like that better than my origional thought of having a "scissor" with mrks for diferent widths on it. This could be done buy putting a bolt in the center of two boards and it would always open square. Soryy I don't have a cool drawing to show you :P

#39

Re: Wooden ramps... Work great!!

Vader: Good idea! That would take a bit more fab than what I had in mind, but is definetly a slick idea. At first I wasnt sure what you had goin on....but then I realized they were hinged and could tuck away.

My idea was to have 2x4 cut to the length you need for each car. So I might have a pair cut for my trans am. A pair cut for my jeep. A pair cut for the girls car...etc etc. Then have them fit onto the ramps with big dowels or slots or something. I havent given it a whole lot of thought yet....because my car is at home on top of them for awhile while I re-work somethings.

I will say this. These things are really fun to try to move around. They are so darn heavy. Its a win/lose situation. On one hand, it is pretty hard to move them around with just one person. The handles I installed work great...but still. However, the weight is really nice when you are bumping up onto them because they dont want to slide or move around too much. Whatever I/we come up with for spacing these suckers, has to be something easy to manage and line up while trying to muscle the ramps into place.

Maybe Im just a wuss

Justin

My idea was to have 2x4 cut to the length you need for each car. So I might have a pair cut for my trans am. A pair cut for my jeep. A pair cut for the girls car...etc etc. Then have them fit onto the ramps with big dowels or slots or something. I havent given it a whole lot of thought yet....because my car is at home on top of them for awhile while I re-work somethings.

I will say this. These things are really fun to try to move around. They are so darn heavy. Its a win/lose situation. On one hand, it is pretty hard to move them around with just one person. The handles I installed work great...but still. However, the weight is really nice when you are bumping up onto them because they dont want to slide or move around too much. Whatever I/we come up with for spacing these suckers, has to be something easy to manage and line up while trying to muscle the ramps into place.

Maybe Im just a wuss

Justin

#40

Banned

iTrader: (12)

Join Date: Jul 1999

Location: Bertram (outside Austin), TX

Posts: 12,212

Likes: 0

Received 10 Likes

on

10 Posts

Car: 87 GTA

Engine: L98

Transmission: 700R4

Axle/Gears: Dana M78 3.27 posi

Re: Wooden ramps... Work great!!

You talked about the uber-long ramps being heavy. Tat's what I liked about mine. 1 handed, easily lifted. Maybe 4 ft long at the bottom level. Easy to slide in from any direction, even the sides of course.

Next time I go by the guys house I gave them to, I'll try to get a pic of them.

Next time I go by the guys house I gave them to, I'll try to get a pic of them.

#41

Re: Wooden ramps... Work great!!

Yeah I know I complain about them being heavy. But I made them as long as I did for a reason. And I dont have to move them every single day. So its not THAT bad. Once I get my car finished up, I might not use them again until oil change time. 3000 miles from now...probably not until next spring. haha. I made these basically just for building my crossmember and new exhaust piping. That job is what prompted me to do something...and I needed it done quick.

Ide still like to see pictures of your ramps tho if you snap a couple!

Justin

Ide still like to see pictures of your ramps tho if you snap a couple!

Justin

#42

Senior Member

Join Date: Oct 2005

Location: Brooklyn, NY 11208

Posts: 593

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1983 Recaro T/A

Engine: L69

Transmission: MM5

Axle/Gears: 3:73

Re: Wooden ramps... Work great!!

Ghettocruiser, you mind posting your measurements up? I really like your idea. My Car is lowered in the front and it is a bitch to jack this car up.

Oh and nice T/A. It's one of those 3rd gens that flows well with the 4th gen wheels.

Oh and nice T/A. It's one of those 3rd gens that flows well with the 4th gen wheels.

#43

Re: Wooden ramps... Work great!!

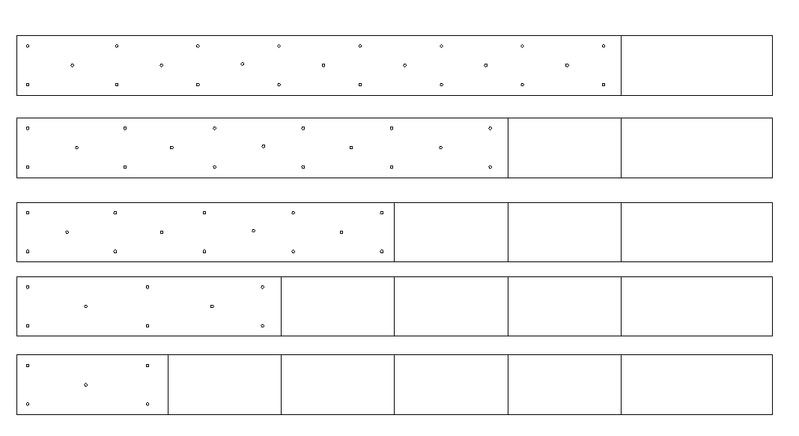

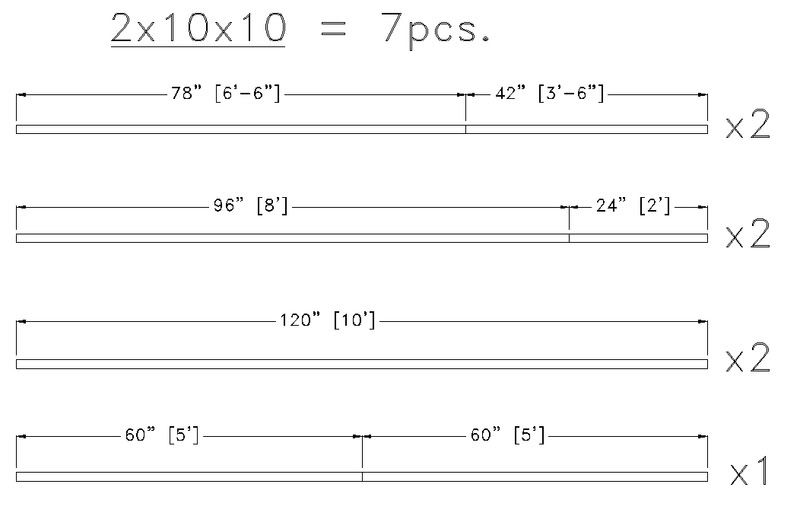

I had a couple requests for dimensions...so instead of just replying to each one I figured Ide just post the info up to make it easy.

Keep in mind you dont have to build them to the exact specs. But the way I have outlined makes no scrap wood and works out perfectly at 7 pcs of lumber. You could leave the last level off and you would only need 5 pcs then.

Here is a profile view of the ramps showing the boards, as well as the wheels relative to the boards. Only thing not shown is the taller wheel stop. Im leaving the wheel stop you to you, but two 2x3's nailed down work good for me.

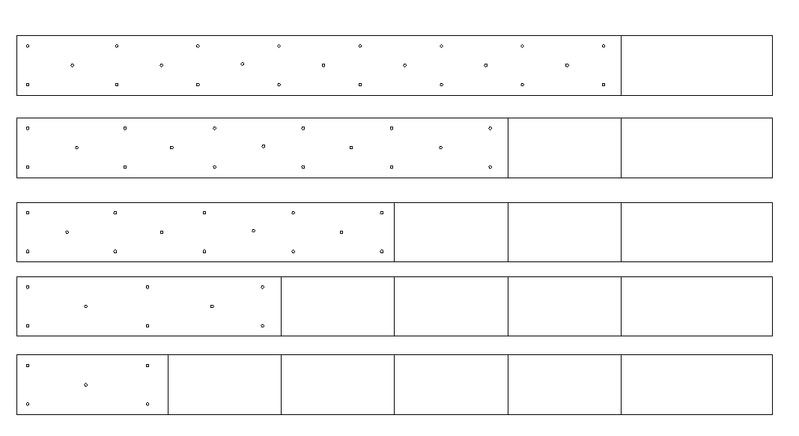

Here is a plan view of them, just to show basically how I screwed them together. I knew I didnt have to go overboard with screws, but I did the ones in the middle to help flatten the slightly curved pieces out. I used 2.5" screws for treated lumber. They have the green coating. Pleny of screw to hold them together.

Finally, here is a basic materials list. If you have any trouble understanding it, let me know. But its pretty self explanitory. It shows the size of lumber I used, how many pieces, and where to cut each piece to make it come out even.

If you have any questions feel free to ask, as well as if you have any suggestions for better ramps, or different ramps, feel free to upgrade the design.

Justin

Keep in mind you dont have to build them to the exact specs. But the way I have outlined makes no scrap wood and works out perfectly at 7 pcs of lumber. You could leave the last level off and you would only need 5 pcs then.

Here is a profile view of the ramps showing the boards, as well as the wheels relative to the boards. Only thing not shown is the taller wheel stop. Im leaving the wheel stop you to you, but two 2x3's nailed down work good for me.

Here is a plan view of them, just to show basically how I screwed them together. I knew I didnt have to go overboard with screws, but I did the ones in the middle to help flatten the slightly curved pieces out. I used 2.5" screws for treated lumber. They have the green coating. Pleny of screw to hold them together.

Finally, here is a basic materials list. If you have any trouble understanding it, let me know. But its pretty self explanitory. It shows the size of lumber I used, how many pieces, and where to cut each piece to make it come out even.

If you have any questions feel free to ask, as well as if you have any suggestions for better ramps, or different ramps, feel free to upgrade the design.

Justin

#44

Supreme Member

Join Date: Jun 2003

Location: Toronto CANADA - GM Parts Rep.

Posts: 1,386

Likes: 0

Received 2 Likes

on

2 Posts

Car: 1987 Iroc Z28

Engine: The KING of the 3rd gen TPI's.

Transmission: Beefed up T5

Axle/Gears: Aussie 3.45's

Re: Wooden ramps... Work great!!

Hey I was thinking about building a similair setup.

I currently have sloped (angled) wooden ramps I use at home mainly for doing my own oil changes. It's tough driving up the ramps because there isn't enough clearance for the front skirts (as the car is pretty low to the ground) and I end up mashing the bottom part of my front skirt.

I don't wanna jack the car up on one side as this will put stress on it. The only way to get under there (short of an inground pit) would be a set of these ramps that "step" up in increments as opposed to the short angled ones.

Looks like they take up space, but hey I guess you can't have everyhting.

Thumbs up.

I currently have sloped (angled) wooden ramps I use at home mainly for doing my own oil changes. It's tough driving up the ramps because there isn't enough clearance for the front skirts (as the car is pretty low to the ground) and I end up mashing the bottom part of my front skirt.

I don't wanna jack the car up on one side as this will put stress on it. The only way to get under there (short of an inground pit) would be a set of these ramps that "step" up in increments as opposed to the short angled ones.

Looks like they take up space, but hey I guess you can't have everyhting.

Thumbs up.

#45

Re: Wooden ramps... Work great!!

Yeah they do take up space. And actually, I havent tried to store them yet because Ive been using them since the day I built them. However, that was the reason I got treated lumber. Im probably going to put alittle sealer on them, and just lay them outside next to the garage. Should be fine... Our pool deck has been exposed to 10 years of rough weather and it looks great still...same wood. So these should be ok for sure. Besides, in ten years I hope to have a nice garage and a lift...so I can keep these only for emergency back ups. haha.

Justin

Justin

#46

Junior Member

iTrader: (2)

Join Date: Dec 2006

Location: Carrollton IL

Posts: 59

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Camaro RS

Engine: LO3

Transmission: 700r4

Axle/Gears: 273 pegleg

Re: Wooden ramps... Work great!!

Just got done making a set of these, but only three steps though. Just wanted to be able to get my floor jack under the car. They work great, pulled the car right up on them without any help, and that's with single track in the gravel. I imagine, considering what mine weigh, it must take two guys to move yours. Thanks for the diagrams.

Dave B

Dave B

#47

TGO Supporter

Join Date: Oct 2002

Location: Saskatoon, SK, Canada

Posts: 9,067

Likes: 0

Received 1 Like

on

1 Post

Car: '83 Z28, '07 Charger SRT8

Engine: 454ci, 6.1 Hemi

Transmission: TH350, A5

Axle/Gears: 2.73 posi, 3.06 posi

Re: Wooden ramps... Work great!!

Seems like a pretty good idea actually - I've used wood like that before and I'll trust a solid peice of wood over thin stamped steel ramps anyday.

Only change I'd suggest is at the top of the ramp, put a little 'valley' for the car to roll into once its at the top. That way, it cannot roll back untill you drive it off, and it also lets you actually know for certain when the car is in the right position without getting out to look. Something like this is what I mean:

--_TIRE_--____

---------------------------

-------------------------------------------

--------------------------------------------------------------

Those little straps you have on there, while its not a bad idea, are not what you'd need to keep it from rolling back. Those straps are nowhere near strong enough - they will stretch and break if the car ever really moves enough to want to roll off. Great idea, you just need beefier straps for it to work like you want.

A strap going front-to-back OVER the front tires, like many organized burnout contests use, would be even better!

Only change I'd suggest is at the top of the ramp, put a little 'valley' for the car to roll into once its at the top. That way, it cannot roll back untill you drive it off, and it also lets you actually know for certain when the car is in the right position without getting out to look. Something like this is what I mean:

--_TIRE_--____

---------------------------

-------------------------------------------

--------------------------------------------------------------

Those little straps you have on there, while its not a bad idea, are not what you'd need to keep it from rolling back. Those straps are nowhere near strong enough - they will stretch and break if the car ever really moves enough to want to roll off. Great idea, you just need beefier straps for it to work like you want.

A strap going front-to-back OVER the front tires, like many organized burnout contests use, would be even better!

#48

Re: Wooden ramps... Work great!!

Good idea on the recess for the tire to sit in. The pieces of wood I have at the end of mine are strong enough so that just by letting the car drift forward they will stop the car. I can tell when Im at the top without getting out to check. I usually have someone watching anyway just in case. But good idea with the dips. I might have to look into that if I ever re-vamp the ramps in the future to include some of the other good ideas I got on here.

Since the car is basically sitting on level landings, it really doesnt want to roll backwards as much as if it was on an incline. Even in neutral with no parking brake engaged it takes a good shove for it to move back. However, keeping safety in mind, I use wheel chocks. The straps are there for jacking the rear up, since the jack will want to pull the car back.

As for the straps holding... Those straps are stronger than you think. There isnt THAT much force involved if the car were to want to roll down off that top level. Assuming the ramps themselves are on fairly level ground.

But...since I like testing things out, I actually watned to see if the straps would work. I actually put the car in reverse, and tried to back off the ramps while the straps were on. Had my dad watching in the front, and he said the tires never even moved away from the bump stops. If I cant drive off the ramps while its strapped in, its never going to roll of on its own.

Dont recall 100%, but Im pretty sure those straps I used were rated at 1200lbs. In any case, like I said, they arent going to break just from the car trying to roll off on its own.

J.

Since the car is basically sitting on level landings, it really doesnt want to roll backwards as much as if it was on an incline. Even in neutral with no parking brake engaged it takes a good shove for it to move back. However, keeping safety in mind, I use wheel chocks. The straps are there for jacking the rear up, since the jack will want to pull the car back.

As for the straps holding... Those straps are stronger than you think. There isnt THAT much force involved if the car were to want to roll down off that top level. Assuming the ramps themselves are on fairly level ground.

But...since I like testing things out, I actually watned to see if the straps would work. I actually put the car in reverse, and tried to back off the ramps while the straps were on. Had my dad watching in the front, and he said the tires never even moved away from the bump stops. If I cant drive off the ramps while its strapped in, its never going to roll of on its own.

Dont recall 100%, but Im pretty sure those straps I used were rated at 1200lbs. In any case, like I said, they arent going to break just from the car trying to roll off on its own.

J.

Last edited by ghettocruiser; 06-04-2007 at 09:52 AM.

#49

TGO Supporter

Join Date: Aug 2001

Location: NJ/PA

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

Car: Yes

Engine: Many

Transmission: Quite a few

Re: Wooden ramps... Work great!!

you could always find some wheels to bolt to the end of the ramps, right at ground level, and then put the handles on the lower end. When you pick up the lower end (lighter), it would end up being like a wheel barrow or hand-cart, wheel them where you want, and set it back down. Might make it easier to move.

#50

Re: Wooden ramps... Work great!!

The wheel idea would work great! Ive been trying to come up with a way to do it. The wheels have to retract when weight is put on them. OR they have to be positioned just right so they only contact the ground when the boards are tilted up from the opposite end. I just havent come up with a good way to do it yet.

I was thinking about making a simple suspension so that the wheels push the ramp up while weightless, but all the ramp to "bottom out" when there is weight on it. Valve springs might do the trick for that.... For now thought Im just using the lift and drag method. I havent really had to move them since I posted pictures of my car on them the last time. Still havent finished all the work.

Justin

I was thinking about making a simple suspension so that the wheels push the ramp up while weightless, but all the ramp to "bottom out" when there is weight on it. Valve springs might do the trick for that.... For now thought Im just using the lift and drag method. I havent really had to move them since I posted pictures of my car on them the last time. Still havent finished all the work.

Justin