Mid mount motor plate project

#1

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Mid mount motor plate project

It must be the silly season. The racing forum has been dead for a few days now

I'm on to my next project. Yesterday I yanked out the powerglide to replace some clutches and to install a deep pan. The 5 normal thickness clutch disks in the forward hub were upgraded to 7 thin clutch disks. I could have put in 8 if I had purchased the thinner steels. I yanked the extra steels out of a PG I have for spare parts. I need to find another one for more parts soon.

While the transmission was out, I took a good look under the car to see what would be involved to install a mid plate before I reinstall the tranny. Although it may not be a typical install, I got a pretty good idea what's going to be involved and this morning I picked up a mid plate. I didn't feel like trying to make one. It's a .090" steel mid plate.

I should have it completed with pictures before the end of the weekend. The one thing I would like to do but I'm not ready to tackle it yet is to fabricate a removable, aluminum tranny tunnel. It would make removing the bellhousing bolts so much easier. With tranny and flexplate shields,accessing the bellhousing bolts is difficult from the bottom and totally impossible from the top.

Pictures later.

I'm on to my next project. Yesterday I yanked out the powerglide to replace some clutches and to install a deep pan. The 5 normal thickness clutch disks in the forward hub were upgraded to 7 thin clutch disks. I could have put in 8 if I had purchased the thinner steels. I yanked the extra steels out of a PG I have for spare parts. I need to find another one for more parts soon.

While the transmission was out, I took a good look under the car to see what would be involved to install a mid plate before I reinstall the tranny. Although it may not be a typical install, I got a pretty good idea what's going to be involved and this morning I picked up a mid plate. I didn't feel like trying to make one. It's a .090" steel mid plate.

I should have it completed with pictures before the end of the weekend. The one thing I would like to do but I'm not ready to tackle it yet is to fabricate a removable, aluminum tranny tunnel. It would make removing the bellhousing bolts so much easier. With tranny and flexplate shields,accessing the bellhousing bolts is difficult from the bottom and totally impossible from the top.

Pictures later.

#2

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

Here's what I have to start with. The back of the engine. The exhaust collectors were removed to aid in the tranny removal. There's a spacer the same thickness of the midplate behind the flexplate. This positions the flexplate closer to the converter so the converter stays properly positioned on the splines. The .090" increased thickness doesn't affect the starter engagement. It never grabbed all the teeth before. Now it only grabs about half the teeth.

Using the cardboard that the plate was packaged in, a template was made to see where it needed to be trimmed. Some posterboard could also be used if you have some. The frame rail is higher on the passenger side so having it below the frame rail just adds more clearance issues.

The cardboard template is then transferred onto the steel midplate and cut out with a jigsaw.

The trial fit looks good. The hole on the driver's side I believe is for an exhaust pipe. Removing the #8 header tube is going to be very difficult with the midplate in the way. I won't know how difficult it will be until I need to remove it.

I've now painted the midplate. After it dries, I'll reposition to figure out where the mounts will go on the frame. The kit includes a couple of 1-1/2" plates predrilled with mounting holes and gussets for the mount brackets. I'm going to use some same thickness angle iron to make the mounts. The mid plate is supposed to be bolted to the mount brackets with two 3/8" bolts on either side. Drilling holes will be almost impossible. The angle iron mounts will be welded to the frame rails and I may just weld the mid plate right to the mounts. The mid plate doesn't come out when you remove the transmission and doesn't need to come out when you pull the engine. Just drive the bellhousing guide pins out and lift straight up.

Using the cardboard that the plate was packaged in, a template was made to see where it needed to be trimmed. Some posterboard could also be used if you have some. The frame rail is higher on the passenger side so having it below the frame rail just adds more clearance issues.

The cardboard template is then transferred onto the steel midplate and cut out with a jigsaw.

The trial fit looks good. The hole on the driver's side I believe is for an exhaust pipe. Removing the #8 header tube is going to be very difficult with the midplate in the way. I won't know how difficult it will be until I need to remove it.

I've now painted the midplate. After it dries, I'll reposition to figure out where the mounts will go on the frame. The kit includes a couple of 1-1/2" plates predrilled with mounting holes and gussets for the mount brackets. I'm going to use some same thickness angle iron to make the mounts. The mid plate is supposed to be bolted to the mount brackets with two 3/8" bolts on either side. Drilling holes will be almost impossible. The angle iron mounts will be welded to the frame rails and I may just weld the mid plate right to the mounts. The mid plate doesn't come out when you remove the transmission and doesn't need to come out when you pull the engine. Just drive the bellhousing guide pins out and lift straight up.

#3

Senior Member

iTrader: (1)

Join Date: Dec 2000

Location: chicago

Posts: 689

Likes: 0

Received 0 Likes

on

0 Posts

Re: Mid mount motor plate project

nice work. I think its the way to go as it relieves stress on the engine block.Also allows more freedom with accessoiries and exhaust.

My car has front and mid motor plates heres some pics .

My car has front and mid motor plates heres some pics .

#4

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

And it's done. For whatever reasons, I decided to do it as a bolt in. Some angle iron was bolted onto the plate then positioned on the frame rail for welding. The passenger side was tricky. There just wasn't enough frame rail where the bracket was going to go so I extended the bracket with a piece of scrap and gave it a good area to weld. I was also able to get the lower backside slightly for a bit more weld.

Everything was painted black so it's hard to see much. Now I can put the transmission back in. There's still a jack stand and chunk of wood under the engine oil pan. I can't pull it out without lifting the car up higher.

That hole through the floor is an access hole to adjust the band on the powerglide. There's no room from under the car.

Everything was painted black so it's hard to see much. Now I can put the transmission back in. There's still a jack stand and chunk of wood under the engine oil pan. I can't pull it out without lifting the car up higher.

That hole through the floor is an access hole to adjust the band on the powerglide. There's no room from under the car.

Last edited by AlkyIROC; 12-26-2009 at 07:14 PM.

#6

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

I screwed up but it may not be too bad. The back of the engine is sitting lower than before. This means the transmission is also sitting lower. I was going to make a new tranny crossmember anyway so that's not a problem. The header collectors are not jammed up against the floor now and I have a lot more room to access the bellhousing bolts. I can now access the band adjustment bolt from below. I had to readjust the exhaust slightly and hope it's not hanging too low. I'll probably scrape the pipes getting on and off the trailer since I know it was really close before.

The only concern I have now is the driveline angle. The u-joint at the transmission is about 1-1/2" lower than the u-joint at the diff. It's difficult to get a 100% measurement because the car is sitting on 4 jackstands but the driveshaft angle is noticeably different from the transmission output shaft. I'll just have to recheck the driveline angles and make sure the diff pinion is at the same angle as the tranny output shaft. I guess when the car launches and the body separates, the driveshaft may be close to straight with the yokes.

The transmission is completely installed except for adding oil and fabricating a new crossmember. It's hanging off the back of the engine. If I had much better engine travel limiters, I could run it just like that but I like the idea of having some support at the back of the tranny. If the engine is firmly supported at the front and rear, the back of the transmission doesn't need to be supported.

The only concern I have now is the driveline angle. The u-joint at the transmission is about 1-1/2" lower than the u-joint at the diff. It's difficult to get a 100% measurement because the car is sitting on 4 jackstands but the driveshaft angle is noticeably different from the transmission output shaft. I'll just have to recheck the driveline angles and make sure the diff pinion is at the same angle as the tranny output shaft. I guess when the car launches and the body separates, the driveshaft may be close to straight with the yokes.

The transmission is completely installed except for adding oil and fabricating a new crossmember. It's hanging off the back of the engine. If I had much better engine travel limiters, I could run it just like that but I like the idea of having some support at the back of the tranny. If the engine is firmly supported at the front and rear, the back of the transmission doesn't need to be supported.

#7

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

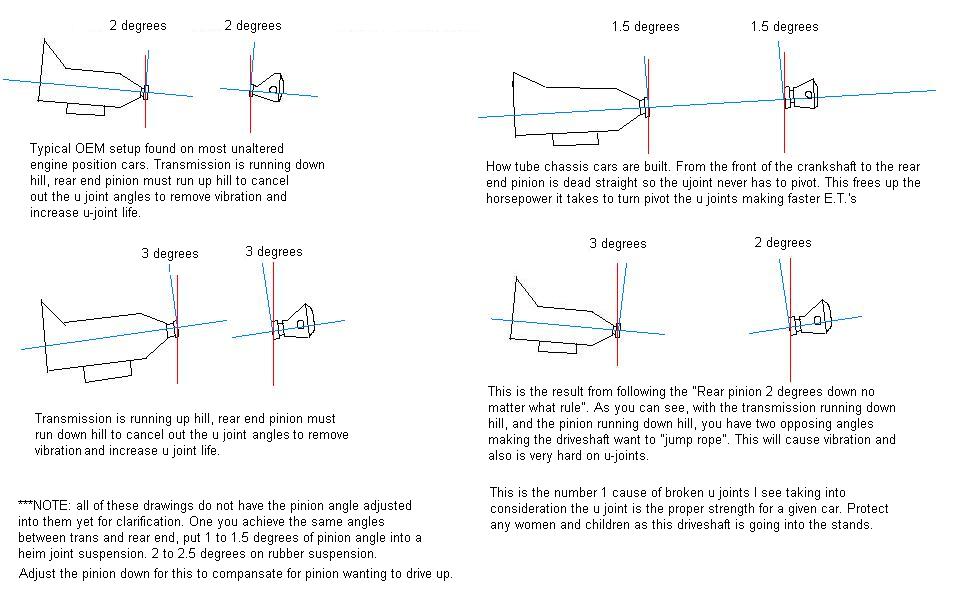

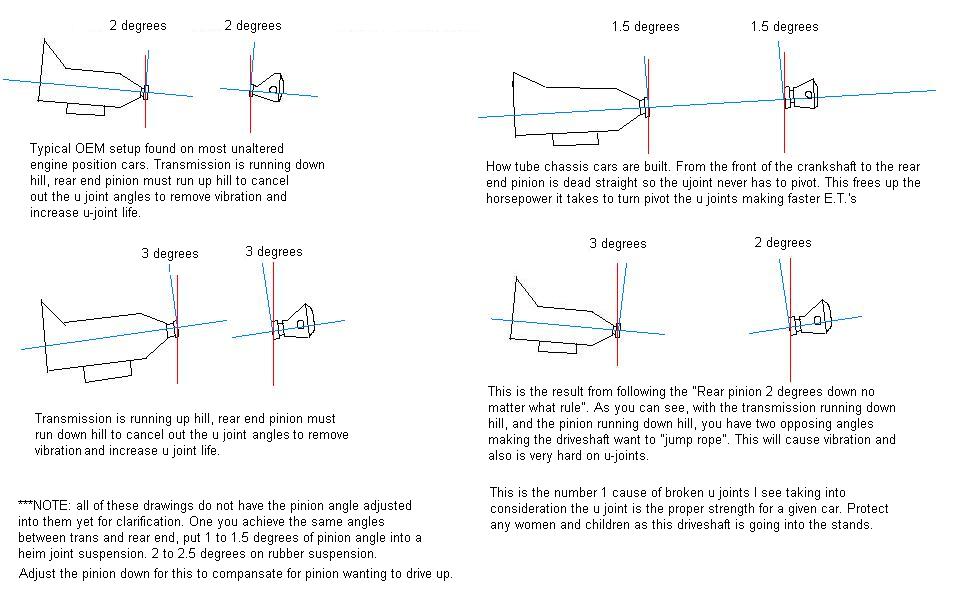

Here's what I need to accomplish. Adjust the diff pinion so it's at the same angle as the transmission output shaft. Top left picture. Angle the diff pinion down 1-2* at the most.

Trending Topics

#8

Junior Member

Join Date: Oct 2009

Location: Waxhaw NC. southeast of Charlotte

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1991 RS Camaro 1979 El Camino

Re: Mid mount motor plate project

I've been here everyday reading, so it's not been that dead here. You seem to have organized your winter projects and knocked them out. The mid plate was a random decision? I can see why you're the moderator here.

#9

Junior Member

Join Date: Dec 2007

Location: fredvegas, va

Posts: 97

Received 0 Likes

on

0 Posts

Car: 91 Z28

Engine: 6.0 LSX 88 Turbo, EFI E85

Transmission: Glide

Axle/Gears: Strange 3:73 9"

Re: Mid mount motor plate project

why don't you put the trans back in, crossmember inc. leave the bolts out of the outboard mounts when all back correct redrill the bolt holes, then you would be back correct..Rob

#10

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

I could try that but it's not that simple. I would need to pull the mid plate out and cut a bit off the top of the driver's side. It's touching the tranny tunnel already. There's also the problem of just getting the mid plate out. The mid plate is supposed to be installed on the front of the mounts. Taking the ring gear off, it "might" drop down enough before hitting the header to be slid out but I doubt it. Raising it up will probably mean both sides will only have enough room on the mount for one bolt so it would probably would be better to weld it in after that. Once everything is in, there's no room to get a drill in to drill new holes. The current holes were drilled with the mid plate and mounts out of the car.

The mid plate was a decision I finally made. I knew I should have had one a long time ago but it was a project that I knew was going to be difficult because of how little room is under the tranny tunnel with the engine and tranny pushed back. This time when I had the tranny out, I lust looked at it differently and figured out it was feasible to do at this time. The only reason you should have a mid plate is if you run a front motor plate and don't use any side engine mounts. I've run without a mid plate for a number of years now and have had my fingers crossed that I wouldn't break the tailshaft housing on the tranny. At least the Powerglide is considerably lighter. I grabbed it and lifted it off the jack yesterday to reposition it. Two of us at work tried to lift a 4L80E last week to put on the back of a pickup and we decided to use a forklift

I'll live with how it's set up for now. The increased access outweighs the increased angle.

The mid plate was a decision I finally made. I knew I should have had one a long time ago but it was a project that I knew was going to be difficult because of how little room is under the tranny tunnel with the engine and tranny pushed back. This time when I had the tranny out, I lust looked at it differently and figured out it was feasible to do at this time. The only reason you should have a mid plate is if you run a front motor plate and don't use any side engine mounts. I've run without a mid plate for a number of years now and have had my fingers crossed that I wouldn't break the tailshaft housing on the tranny. At least the Powerglide is considerably lighter. I grabbed it and lifted it off the jack yesterday to reposition it. Two of us at work tried to lift a 4L80E last week to put on the back of a pickup and we decided to use a forklift

I'll live with how it's set up for now. The increased access outweighs the increased angle.

#11

Supreme Member

Join Date: Apr 2002

Location: Southwest Florida

Posts: 4,627

Likes: 0

Received 1 Like

on

1 Post

Car: projects.......

Re: Mid mount motor plate project

I set pinion angle in relation to the driveshaft angle. I don't even check the trans output angle 'cept at a glance to make sure it's not overly funky.

I've seen what you posted about pinion angle(it's on Rossler's site for that matter) but have always set it off ds angle, and most suspension "gurus" on YB seem to agree.

Misc pics of my mid plate:

I've seen what you posted about pinion angle(it's on Rossler's site for that matter) but have always set it off ds angle, and most suspension "gurus" on YB seem to agree.

Misc pics of my mid plate:

#12

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

Mine might be "overly funky" I won't know until I go down the track. With the driveline angle set up, at least the u-joint will be happy. I'll just lose a small bit of power through the angles of the u-joints. The tranny yoke to driveshaft is 7*. I'd like that to be anywhere from zero to 3.

I finished fabricating a new tranny crossmember and installed it last night. Because it's not really supporting any weight, I made it out of a single piece of 1x1x1/8" square steel tube. If it supports weight, 2 pieces are required. I also incorporated the driveshaft loop into the crossmember. The loop sits a foot behind the crossmember. What were the GM engineers thinking when they designed the floor for the tranny crossmember. The crossmember looks like a pretzel to fit the stupid angles.

I managed to fire the car up today to check the tranny fluid. Engine hasn't run since the end of September. Even with the gas primer, it took a few minutes before it would catch. It's below freezing outside and I needed to open the garage door after the engine started. It didn't take long for my eyes to start burning from the alcohol fumes. The cold engine idles a little rich.

I finished fabricating a new tranny crossmember and installed it last night. Because it's not really supporting any weight, I made it out of a single piece of 1x1x1/8" square steel tube. If it supports weight, 2 pieces are required. I also incorporated the driveshaft loop into the crossmember. The loop sits a foot behind the crossmember. What were the GM engineers thinking when they designed the floor for the tranny crossmember. The crossmember looks like a pretzel to fit the stupid angles.

I managed to fire the car up today to check the tranny fluid. Engine hasn't run since the end of September. Even with the gas primer, it took a few minutes before it would catch. It's below freezing outside and I needed to open the garage door after the engine started. It didn't take long for my eyes to start burning from the alcohol fumes. The cold engine idles a little rich.

#13

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

OK, I've done a bunch of research about driveshaft and pinion angles. First of all, to avoid positive and negative confusion, all angles are in relation to the front. With the back of the transmission lower that the crankshaft balancer, that's a positive angle. With the driveshaft lower in the front than in the rear, that's a negative angle.

When we think of pinion angle, it's the angle between the driveshaft and the diff pinion. The maximum angle allowed is rpm related. The faster the driveshaft spins, the less the angle should be. Lots of charts available so I won't get into that. Different types of suspension require different amounts of pinion angles. Leaf springs because of how much wrap they have are the worst. My 4-link should have little to no wrap.

I did however find some interesting information about driveline angles. That's the angle of the transmission yoke in relation to the diff yoke. I don't know what either of mine are in relation to the ground but using my digital protractor, I set it for zero off the driveshaft yoke. The angle is actually positive as the car currently sits but I could lift the front of the car 5 feet off the ground and still set the tranny pinion angle as zero.

With the tranny yoke at zero, I set the diff yoke at -1 so in relation to the tranny, the diff is pointing down 1 degree although it's actually pointing upward the same as the tranny and engine while the driveshaft points down from the diff. This is a driveline angle with -1 degree of pinion angle added in. If I set the diff pinion to zero then it would be a perfect driveline angle of zero degrees.

The maximum driveline angle allowed depends on the length of the driveshaft. Take the length of the driveshaft and divide by 5. I don't know where they came up with this number but that's what's used.

I measured my driveshaft. Measurement is from the center of the driveshaft u-joint to center of driveshaft u-joint. Think of the driveshaft with just u-joints and no front yoke. If the other half of the u-joint was clamped in a vise, the driveshaft would pivot on the center of the half that's in the full round ends.

My driveshaft is 44.5". Divided by 5 gives a maximum allowable angle for a u-joint of 8.9*. The angle of my driveshaft in relation to the tranny yoke is 7* and with the diff pinion down 1 degree, the angle in relation to the driveshaft is 6*. Both are within the 8.9*. Having that 1 degree may lower that maximum slightly since the diff and tranny are not parallel angles.

Changing the ride height will change the angles. If I raise the ride height, it will move the transmission slightly higher. The diff pinion height is set by the tire height and with a 32" tall tire, it's quite high. Changing the ride height won't change the driveline angle or if it does, it won't be enough to notice but it will change the pinion angle because the angle in relation between the driveshaft and both yokes will change. The higher the ride height is, the higher the tranny yoke moves up.

If you see pictures of my car going down the track, my front suspension stays extended. This means the tranny will be sitting a lot higher. Although the rear tires will get some tire growth, the increased height of the diff pinion won't be as great.

I think using that logic, I should be OK. Even though I don't like the look of those angles, my driveshaft and u-joints should survive racing. If I spit the driveshaft out from under the car next year, I'll know I screwed up.

When we think of pinion angle, it's the angle between the driveshaft and the diff pinion. The maximum angle allowed is rpm related. The faster the driveshaft spins, the less the angle should be. Lots of charts available so I won't get into that. Different types of suspension require different amounts of pinion angles. Leaf springs because of how much wrap they have are the worst. My 4-link should have little to no wrap.

I did however find some interesting information about driveline angles. That's the angle of the transmission yoke in relation to the diff yoke. I don't know what either of mine are in relation to the ground but using my digital protractor, I set it for zero off the driveshaft yoke. The angle is actually positive as the car currently sits but I could lift the front of the car 5 feet off the ground and still set the tranny pinion angle as zero.

With the tranny yoke at zero, I set the diff yoke at -1 so in relation to the tranny, the diff is pointing down 1 degree although it's actually pointing upward the same as the tranny and engine while the driveshaft points down from the diff. This is a driveline angle with -1 degree of pinion angle added in. If I set the diff pinion to zero then it would be a perfect driveline angle of zero degrees.

The maximum driveline angle allowed depends on the length of the driveshaft. Take the length of the driveshaft and divide by 5. I don't know where they came up with this number but that's what's used.

I measured my driveshaft. Measurement is from the center of the driveshaft u-joint to center of driveshaft u-joint. Think of the driveshaft with just u-joints and no front yoke. If the other half of the u-joint was clamped in a vise, the driveshaft would pivot on the center of the half that's in the full round ends.

My driveshaft is 44.5". Divided by 5 gives a maximum allowable angle for a u-joint of 8.9*. The angle of my driveshaft in relation to the tranny yoke is 7* and with the diff pinion down 1 degree, the angle in relation to the driveshaft is 6*. Both are within the 8.9*. Having that 1 degree may lower that maximum slightly since the diff and tranny are not parallel angles.

Changing the ride height will change the angles. If I raise the ride height, it will move the transmission slightly higher. The diff pinion height is set by the tire height and with a 32" tall tire, it's quite high. Changing the ride height won't change the driveline angle or if it does, it won't be enough to notice but it will change the pinion angle because the angle in relation between the driveshaft and both yokes will change. The higher the ride height is, the higher the tranny yoke moves up.

If you see pictures of my car going down the track, my front suspension stays extended. This means the tranny will be sitting a lot higher. Although the rear tires will get some tire growth, the increased height of the diff pinion won't be as great.

I think using that logic, I should be OK. Even though I don't like the look of those angles, my driveshaft and u-joints should survive racing. If I spit the driveshaft out from under the car next year, I'll know I screwed up.

Last edited by AlkyIROC; 12-28-2009 at 08:44 PM.

#14

Junior Member

Join Date: Feb 2004

Location: Omaha, NE

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Trans AM & 69 RS/SS Camaro

Engine: 400 "little M"

Transmission: Tremec TKO II

Axle/Gears: Moser 9" with 3.50's

Re: Mid mount motor plate project

AlkyIroc. did the new driveline angle make a difference?

#15

Moderator

Thread Starter

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,108

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Mid mount motor plate project

I still haven't been on track yet this year. Opening day is this weekend and it looks like we'll be rained out.

I don't expect there to be any issues but next winter I'm going to change it. I want the tranny pointed at the diff yoke to reduce the driveline angle as much as possible. That means I'll need to cut out the tranny tunnel to move the tranny up a lot higher. I don't know how much clearance problems I'll have with the header collectors hitting the underside of the floor. I can't drop the engine down any more than it currently sits to gain more collector clearance.

I don't expect there to be any issues but next winter I'm going to change it. I want the tranny pointed at the diff yoke to reduce the driveline angle as much as possible. That means I'll need to cut out the tranny tunnel to move the tranny up a lot higher. I don't know how much clearance problems I'll have with the header collectors hitting the underside of the floor. I can't drop the engine down any more than it currently sits to gain more collector clearance.

Thread

Thread Starter

Forum

Replies

Last Post

mhatfield 14

Tech / General Engine

5

10-24-2015 07:48 AM

mdtoren

Tech / General Engine

0

08-16-2015 05:45 PM