Help with solid pinion spacer

#1

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Help with solid pinion spacer

I just gathered all my parts together and started my 9 bolt rear rebuild. My old one had a busted spider that destroyed the carrier. So I got a rebuilt 3 series and some good used 308 gears from Glen at 9bolt. Was originally 277 series 2. Got my pinion races in with original spacer behind the inner race. New bearing pressed on then put the pinion into the case. Put my Raetech solid pinion spacer in with no spacers. Outer bearing in and yoke on. Can't even get close to any preload. There is actually slop in the bearings yet. After a lot of messing around and measuring I found out that the spacer is a bit to big. I could probably crush a sleeve to work but I really would like to use the solid spacer. Anyone ever had this problem?? Is there any way to remedy it??

I installed the pinion with no spacer and roughly checked backlash and it is very close. So more shims behind inner race won't work. Any help would be greatly appreciated. Thanks

I installed the pinion with no spacer and roughly checked backlash and it is very close. So more shims behind inner race won't work. Any help would be greatly appreciated. Thanks

#2

Re: Help with solid pinion spacer

Have you already done your trial assemblies and checked the pattern?

There is nothing wrong with the crush spacers. Seems like you have the wrong solid spacer.

There is nothing wrong with the crush spacers. Seems like you have the wrong solid spacer.

#3

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

That's what I had figured. Thought the solid spacer might make set up a little easier. Supposed to add a little strength too. Was cheap enough I figured why not.

Haven't done a pattern check yet. Was just trying to set the preload. Figured I just drop the carrier in to see if the pinion depth was close. I'll set the preload with no spacer then do a pattern check and put the new crush sleeve in when all is good.

Thanks for the info. This is my first attempt at rebuilding a diff. So it's been a real learning experience. This forum has been a great help. Thanks again!!

Haven't done a pattern check yet. Was just trying to set the preload. Figured I just drop the carrier in to see if the pinion depth was close. I'll set the preload with no spacer then do a pattern check and put the new crush sleeve in when all is good.

Thanks for the info. This is my first attempt at rebuilding a diff. So it's been a real learning experience. This forum has been a great help. Thanks again!!

#4

Re: Help with solid pinion spacer

You can't set the pinion bearing preload with the spacer until you have the pinion depth set. If you set the bearing preload and then change the pinion depth your bearing preload will change and you will have to start over. Do the bearing preload with the spacer on the final assembly.

#5

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

That is why I thought the solid spacer and shims would make it easier. If the depth had to be changed I could just add or remove shims from the solid spacer as I added or removed them from beneath the rear pinion cone The plan now was to set the preload with no spacer or crush sleeve, drop the carrier in then do a pattern check. If all was good then add the crush sleeve and reset the preload.

But now I have run in to another problem. With no spacer at all I can't get any preload either. My yoke bottoms out on the spline!!!

Ever heard of anyone having to use spacers between the yoke and outer pinion bearing bearing??

Or have I got something else wrong. Wrong bearing set perhaps. It's a Yukon set from Hawks. Everything fit. But it did come with two rear pinion bearings. The one had a slightly smaller cone. Not sure what that one is for??Or could it be something different with this pinion shaft from 9bolt. I noticed that around here you can't get 308 gears on a 3 series carrier but he got me a used set from Australia.

I think I'm gonna try my old 277 pinion shaft just to see if it fits the same. If it fits good I will be stuck for a solution to get the 308 pinion to work?? Any ideas would be greatly appreciated. Gonna take a break from this for a bit and install the new gas tank. Frustrating !!

But now I have run in to another problem. With no spacer at all I can't get any preload either. My yoke bottoms out on the spline!!!

Ever heard of anyone having to use spacers between the yoke and outer pinion bearing bearing??

Or have I got something else wrong. Wrong bearing set perhaps. It's a Yukon set from Hawks. Everything fit. But it did come with two rear pinion bearings. The one had a slightly smaller cone. Not sure what that one is for??Or could it be something different with this pinion shaft from 9bolt. I noticed that around here you can't get 308 gears on a 3 series carrier but he got me a used set from Australia.

I think I'm gonna try my old 277 pinion shaft just to see if it fits the same. If it fits good I will be stuck for a solution to get the 308 pinion to work?? Any ideas would be greatly appreciated. Gonna take a break from this for a bit and install the new gas tank. Frustrating !!

#6

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

Installing the gas tank will give you a lot less room to work on the rear diff.

big gear head gave the correct answer: You can't set the pinion bearing preload with the spacer until you have the pinion depth set.

big gear head gave the correct answer: You can't set the pinion bearing preload with the spacer until you have the pinion depth set.

#7

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

The diff is on the bench. When it blew up we decided it was a good time to update the suspension with new bars and arms. As well as replace the leaking gas tank and faulty fuel level sending unit. Decided on a new pump too. Pulled the diff out tore it down. Sandblasted and painted. Now finally got all the parts for the guts.

I kinda jumped the the gun on the yoke bottoming out. My little electric impact just didn't have the power to pull the spines further. Guess a little different wear between the yoke and the spline made a little more force necessary. It's all good now.

Is it not necessary to set the preload ( at least roughly) to get the bearings set before checking pinion depth?? That's what I have done. With no crush sleeve in though.

Maybe be get time this week to get the carrier in and check the backlash and pattern

Again I am totally new to this so any and all input is very much appreciated.

I kinda jumped the the gun on the yoke bottoming out. My little electric impact just didn't have the power to pull the spines further. Guess a little different wear between the yoke and the spline made a little more force necessary. It's all good now.

Is it not necessary to set the preload ( at least roughly) to get the bearings set before checking pinion depth?? That's what I have done. With no crush sleeve in though.

Maybe be get time this week to get the carrier in and check the backlash and pattern

Again I am totally new to this so any and all input is very much appreciated.

Trending Topics

#8

Re: Help with solid pinion spacer

Set the pinion bearing preload without the spacer for all trial assemblies. When you have the pinion depth set correctly then install the spacer and set the bearing preload for the last time.

#9

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Thanks big gear head. That'll be the plan now. Soon as I get a chance I'll get back at it. I'll post back on results. Hopefully not too much messing around to get good pattern

#10

Re: Help with solid pinion spacer

Just so you know, a used gear isn't going to give you the same pattern as a new gear. Usually you have to set up a used gear by the coast pattern and forget about the drive pattern. Don't get frustrated when trying to get a good pattern because it might not happen. Post pictures and we will try to help you through it.

#11

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

Now you got it. Just so you know, you do NOT use an impact gun to compress the crush sleeve and set the bearing preload. BIG breaker bar here. You need to come up on it slowly. When I did mine under the car, it took a 4' to 6' pipe on the breaker bar and pulling on it with everything I had.

You can still use the solid pinion spacer. Set it up proper with the crush sleeve, and then take it back apart, measure the sleeve, and use the solid spacer with shims to the same measurement.

You can still use the solid pinion spacer. Set it up proper with the crush sleeve, and then take it back apart, measure the sleeve, and use the solid spacer with shims to the same measurement.

#12

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,046

Received 1,668 Likes

on

1,266 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: Help with solid pinion spacer

Good advice on the breaker bar: a typical 1/2" impact usually doesn't have enough nads to tighten it enough. But then, with a crush sleeve, it's still nowhere near as tight as the nut could be if it was brought to its full torque; you have to stop tightening when the sleeve is crushed enough; which is one of the things that makes a solid spacer better. You can keep on tightening until it screams for mercy, and thus won't back off or randomly "loosen" (actually that's not what happens, but w/e), and it doesn't affect the preload.

Usually for depth setting I put em together with no spacer at all; tighten CAREFULLY with a regular ratchet or whatever to near the correct preload, and STOP before reaching it; do the setting & checking & selecting; then at the very end, install the spacer w/shims. Keep in mind that without anything between the bearings, it's SOOOOOOOOPER EEEEEEEEEEEEEEEEZY to overtighten: it only takes a few ft-lbs on the nut to get full preload on the bearings. Think, how you install front wheel bearings; it's EXACTLY the same situation. In fact, back in the day, pinions used no spacer at all and a cotter pin on the nut, EXACTLY like front wheel brgs. Up until "classic" trucks or thereabouts. It wasn't until drive shaft speeds began to regularly exceed the RPMs at which a cotter pin was no longer strong enough to avoid getting sheared, that they changed to lock nuts and crush sleeves.

For holding the pinion still while tightening the nut, make a tool out of about a 4' piece of like 1/4" x 1-1/2" strip stock. Use a similarly long breaker bar, or a piece of steel water pipe as a "cheater" on the handle. Be careful though, it's REEEEEEL EEEEEEZY to lunch out a cheeeeeeeep breaker bar or socket like HF or the like, by getting carried away with this.

Usually for depth setting I put em together with no spacer at all; tighten CAREFULLY with a regular ratchet or whatever to near the correct preload, and STOP before reaching it; do the setting & checking & selecting; then at the very end, install the spacer w/shims. Keep in mind that without anything between the bearings, it's SOOOOOOOOPER EEEEEEEEEEEEEEEEZY to overtighten: it only takes a few ft-lbs on the nut to get full preload on the bearings. Think, how you install front wheel bearings; it's EXACTLY the same situation. In fact, back in the day, pinions used no spacer at all and a cotter pin on the nut, EXACTLY like front wheel brgs. Up until "classic" trucks or thereabouts. It wasn't until drive shaft speeds began to regularly exceed the RPMs at which a cotter pin was no longer strong enough to avoid getting sheared, that they changed to lock nuts and crush sleeves.

For holding the pinion still while tightening the nut, make a tool out of about a 4' piece of like 1/4" x 1-1/2" strip stock. Use a similarly long breaker bar, or a piece of steel water pipe as a "cheater" on the handle. Be careful though, it's REEEEEEL EEEEEEZY to lunch out a cheeeeeeeep breaker bar or socket like HF or the like, by getting carried away with this.

Last edited by sofakingdom; 03-07-2017 at 11:45 AM.

#13

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

#14

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Just uploaded a couple of pics of pattern check. I have the backlash set at .008. I'm just wondering what amount of shims to start with under the pinion to get closer. Thanks for the offer of help Big gear head. Gonna have to take you up on that one. Knocking out that race could get old real fast. Never mind removing and installing the carrier. Any info would be a lot better than a guess.

#15

Re: Help with solid pinion spacer

Looks like it's way off right now. I'd add .010 to start with and try again. This is a lot of work, so be patient.

Be sure that the race seats completely each time you install it. Your shims may get damaged from driving the race out, so be careful with them. Some people find shims that fit behind the bearing instead of putting them behind the race. If you have a press and a bearing separator this would probably be easier.

Be sure that the race seats completely each time you install it. Your shims may get damaged from driving the race out, so be careful with them. Some people find shims that fit behind the bearing instead of putting them behind the race. If you have a press and a bearing separator this would probably be easier.

#16

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Thanks for the info. I'll start with 010 and see where that gets it to. Don't think I could remove the bearing from the pinion shaft without damaging it. So I'll stick to the race spacers.

Thanks again

Thanks again

#17

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Just wondering Can I expect raising the pinion to change my backlash. Will it tighten it up??

#19

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Kinda thought so. Starting to understand why T&D shops charge so much. But at least this way I know it's set up right!!

#20

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Well your right. This take ALOT of patience. I'll post some pics of pattern. I've gone up to .050 behind the pinion. Kinda looking to push the pattern more into the Center toward the valley. But it ain't happening

#22

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Last edited by 89rubberburner; 03-12-2017 at 07:23 PM. Reason: Pictures didn't insert

#23

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

This may be a stupid question, but why are you putting shims behind the race?

Is this something unique to 9 bolts? And other rear I've worked on, the shims go

behind the pinion bearing. You can hone out your old bearing to make a checking

bearing so you don't have to press it off the pinion if corrections are needed.

Do you have a target pinion depth measurement you are going for?

Is this something unique to 9 bolts? And other rear I've worked on, the shims go

behind the pinion bearing. You can hone out your old bearing to make a checking

bearing so you don't have to press it off the pinion if corrections are needed.

Do you have a target pinion depth measurement you are going for?

#24

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

That is where the spacers were when i tore it down. It actually makes more sense to me to have them there. the closer the pinion gear is to the bearing the stronger it should be. Less leverage on the bearing that way. Not that the difference could be measured. But in theory. I actually did hone my old race down a bit to make it easier to remove.

I am just trying to get a decent gear pattern. No Idea what the proper pinion depth should be or how to measure it.

I am just trying to get a decent gear pattern. No Idea what the proper pinion depth should be or how to measure it.

#25

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

Without that number, you will have to use a best guess if you are to ever arrive at an acceptable contact pattern. Call the place you got the gears from, they might provide a good number as a starting point.

#26

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

The gears are used. Got them from 9Bolt. The way i understand it i would need a pinion depth gauge. I dont have one of those. Would be nice if there was some numbers that correspond to a measurment with a caliper from the center of the carrier to the face.

#27

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

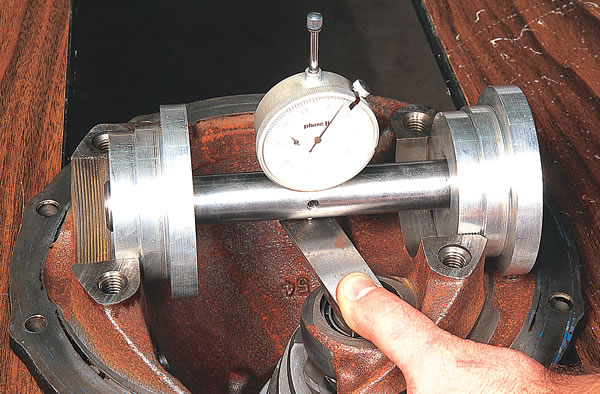

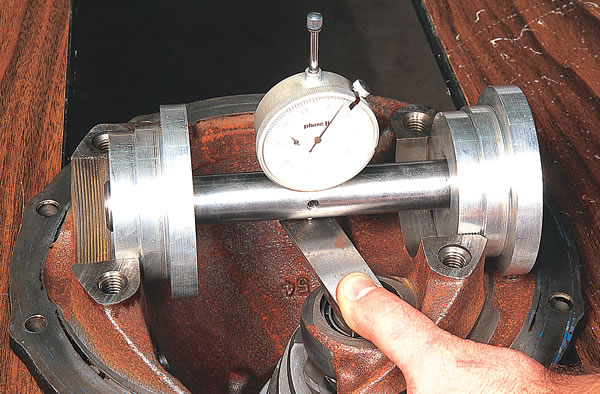

Got a machine shop nearby, or a technical school with a machine shop?

If so, I can tell you of a way that you can measure the P.D. at home

with a digital or dial caliper. But you still need a good target P.D. number

for those gears. Maybe another member can provide one.

If so, I can tell you of a way that you can measure the P.D. at home

with a digital or dial caliper. But you still need a good target P.D. number

for those gears. Maybe another member can provide one.

Last edited by NoEmissions84TA; 03-12-2017 at 10:10 PM.

#28

Re: Help with solid pinion spacer

This isn't going well. That much shim should have got it close. It still needs to go deeper. Keep adding shim and see how it goes, but I'm not getting a good feeling about this.

Yes, the 9 bolt, many of the Dana rear ends and probably some others have the shims behind the race and not the bearing.

Yes, the 9 bolt, many of the Dana rear ends and probably some others have the shims behind the race and not the bearing.

#29

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

#30

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

#31

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

http://www.hotrod.com/articles/t-and...on-depth-tool/

This pics shows how to measure PD on a Ford 9", but you get the idea.

T & D Machine

A $29 Pinion-Depth Tool That Really Works

Somebody copied my idea:

from: http://www.jeepforum.com/forum/f8/fu...setup-1176780/

This pics shows how to measure PD on a Ford 9", but you get the idea.

T & D Machine

A $29 Pinion-Depth Tool That Really Works

Somebody copied my idea:

from: http://www.jeepforum.com/forum/f8/fu...setup-1176780/

Last edited by NoEmissions84TA; 03-13-2017 at 07:03 PM.

#32

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

From what I have read, your shim should be about .020" - .035".

#33

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

.020 is what was in the factory gears. With these gears it barely gave any contact at all. I'm at .060. I'll send an email off to Glen at 9bolt but I doubt he'll be able to give me a pinion depth number for these 308's. Doesn't hurt to try.

In the meantime I'll try adding a little more shim and see what it does.

In the meantime I'll try adding a little more shim and see what it does.

#34

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

More info I found: see attached.

Also, when you get to this point, here's a cool tip:

Grind the locking portion off a spare pinion nut to make bearing preload setup easier.

Also, when you get to this point, here's a cool tip:

Grind the locking portion off a spare pinion nut to make bearing preload setup easier.

#35

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

Used Gears

Checking the pattern on used gear sets requires a different procedure. Ignore the drive side of the pattern; instead, concentrate on the coast pattern only.

This is because the drive side already has wear from use, and the markings look like new patterns.

http://www.chevydiy.com/how-to-insta...axle-assembly-

Checking the pattern on used gear sets requires a different procedure. Ignore the drive side of the pattern; instead, concentrate on the coast pattern only.

This is because the drive side already has wear from use, and the markings look like new patterns.

http://www.chevydiy.com/how-to-insta...axle-assembly-

Last edited by NoEmissions84TA; 03-13-2017 at 07:59 PM.

#36

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

This the closest pattern I can match to what you have. (attached)

#37

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Thanks for the tips. No need to grind anything off the old pinion nut. It's been on and off so many times that there is no "locking" left. If I get a chance to mess with it this week I'll add some more shims and post some more pics.

#38

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Had a couple spare hours tonite This is what we did with it.

These three are with .070 Better I think??

These three are with .080

Do i dare go any higher? I know you are supposed to ignore the drive side but it is starting to get deep into the valley. The coast side is moved up and deeper. But still no where near the nice round patterns that come in the book with the bearing set. Don't know if it helps any but I took a couple pictures of the pinion with .070 under it.

These three are with .070 Better I think??

These three are with .080

Do i dare go any higher? I know you are supposed to ignore the drive side but it is starting to get deep into the valley. The coast side is moved up and deeper. But still no where near the nice round patterns that come in the book with the bearing set. Don't know if it helps any but I took a couple pictures of the pinion with .070 under it.

Last edited by 89rubberburner; 03-15-2017 at 09:56 PM. Reason: Pictures didn't post

#39

Re: Help with solid pinion spacer

Pics don't work. No one can see images that are stored in a private place. Look's like they're saved in your email or something similar. You can attach them to your forum message and upload them to the forum, or use an image host like photobucket, and link them here.

#40

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Tried something different this time. Guess that don't work. I'll repost them

#43

Re: Help with solid pinion spacer

Are you sure that you have the right bearing and race in this? If the race is off by 1 number it can cause big problems like this. I'm wondering if your race is too thin.

#44

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: Help with solid pinion spacer

And all these patterns are with about .008" backlash?

Also, are you holding the ring gear back (resistance)

while you are checking the patterns? You should be.

Just like it would be in the car. Turn the pinion, keep some

resistance on the ring gear.

BTW, EASY on the marking compound. Using WAY too much.

Also, are you holding the ring gear back (resistance)

while you are checking the patterns? You should be.

Just like it would be in the car. Turn the pinion, keep some

resistance on the ring gear.

BTW, EASY on the marking compound. Using WAY too much.

Last edited by NoEmissions84TA; 03-16-2017 at 02:03 AM.

#45

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

The new race is the same number as the one I removed. I haven't removed the bearing from my old pinion so I'm not sure about that.

All the pictures are with .007 - .008 backlash. The backlash hasn't changed a lot by increasing pinion height. I think I've only had to move about .002 to keep it in spec.

I have been holding the yoke with a rag while turning the ring gear

All the pictures are with .007 - .008 backlash. The backlash hasn't changed a lot by increasing pinion height. I think I've only had to move about .002 to keep it in spec.

I have been holding the yoke with a rag while turning the ring gear

#47

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

Me either. I'll see if I can find any difference between the original pinion shaft and this .308 pinion shaft.

If I can get a decent pattern at least that solid pinion spacer will work now. Kinda forgot how this whole thread got started

If I can get a decent pattern at least that solid pinion spacer will work now. Kinda forgot how this whole thread got started

#48

Re: Help with solid pinion spacer

I think you need to get the pinion bearing sorted out before going any farther. Remove the pinion bearing from your old pinion gear and check the number on it and check the bearing that is on the new pinion gear. This is the bearing that Ratech has listed. http://www.ratechmfg.com/pop_up_order%208004.htm Randy's has a KOYO HM88610 and HM88649 listed.

Last edited by big gear head; 03-16-2017 at 11:59 AM.

#49

Re: Help with solid pinion spacer

I think you might be better off contacting 9bolt and asking them about the bearing and race. There might be different bearings that work with different gears or housings and you might not have the correct one for what you are working on.

#50

Junior Member

Thread Starter

Join Date: Mar 2017

Location: Saskatchewan Canada

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Formula

Engine: 350

Transmission: 700R4

Axle/Gears: 9Bolt 308 gears

Re: Help with solid pinion spacer

I have compared the bearings that came outa the diff with the old gears. The ones that came in the Yukon set are the same. Both the bearings and races are Timken and the same number.

After a few phone calls I have found out what the fifth bearing in the Yukon set is for. Apparently some of the early 9bolts came with a smaller inner pinion bearing and race. It must be common enough that Yukon sends both bearings but yet I couldn't find anyone who has come across the smaller one.

The gears from the earlier ones are interchangeable with the later ones. Supposed to be little difference.

The 308 gears I got still had the old bearing on the pinion and of course with my luck it was the older style. I had removed it and put the new larger one on.

So so all shoulda worked out good. Yet I find myself having to pile a lot of shims under the pinion. Everyone said to go by the pinion depth number....when I said that I didn't have that number they said to go by gear pattern then.

I asked about running 080 under the pinion and apparently it does happen. One guy told me that he has added more than .1 to bring a pinion up to the stamped pinion depth.

After a few phone calls I have found out what the fifth bearing in the Yukon set is for. Apparently some of the early 9bolts came with a smaller inner pinion bearing and race. It must be common enough that Yukon sends both bearings but yet I couldn't find anyone who has come across the smaller one.

The gears from the earlier ones are interchangeable with the later ones. Supposed to be little difference.

The 308 gears I got still had the old bearing on the pinion and of course with my luck it was the older style. I had removed it and put the new larger one on.

So so all shoulda worked out good. Yet I find myself having to pile a lot of shims under the pinion. Everyone said to go by the pinion depth number....when I said that I didn't have that number they said to go by gear pattern then.

I asked about running 080 under the pinion and apparently it does happen. One guy told me that he has added more than .1 to bring a pinion up to the stamped pinion depth.