Engine torque vs air Impact wrench torque???

#1

Junior Member

Thread Starter

Engine torque vs air Impact wrench torque???

I was thumbing thru a Harbor freight tool catalog and came across an air impact wrench boasting a torque rating of 800Ft.lbs. which isn't uncommon. How is it that air wrenches can produce more torque than most high performance motors??? In the past I used a 1 inch air impact wrench to loosen the lug nuts on the bud and dayton wheels for tractor-trailers. It had a torque rating of 2500ft-lbs. Although it never seemed hard to handle for me. That is, it never twisted the hell out of my wrists or arms.

Last edited by scorpiusx; 12-28-2018 at 03:46 PM. Reason: Clarity

#2

COTM Editor

iTrader: (22)

Join Date: Mar 2001

Posts: 9,901

Likes: 0

Received 1,855 Likes

on

1,270 Posts

Car: '89 Firebird

Engine: 7.0L

Transmission: T56

Re: Engine torque vs air wrench torque???

I don't know how impact drivers are rated but it probably has to do with impulse and not constant torque. The constant torque would be much lower.

Nevertheless there is a lot of energy pent up in a compressed air line.

Nevertheless there is a lot of energy pent up in a compressed air line.

Last edited by QwkTrip; 12-28-2018 at 11:21 AM.

#3

Re: Engine torque vs air wrench torque???

Well that could be a long answer but I'll take a crack at it. To explain you need to know that they produce torque in different manners. The impact uses Newtons 2nd law of F=MA (hammer impact) along with one of the simple machines, the lever, (crank/output shaft) whereas an engine uses the lever (crank throw) with the air fuel mixture ignition being a force applied to a lever via piston/rod to the crank throw. This is a very basic explanation.

Maybe you can think of it this way, the engine is a wrench you pull by hand with a relatively continuous pressure and the impact is the same wrench you are hitting with a hammer. You can get more instant power from the hammer method but only for a moment. Basically its the impact part of the gun that enables it to produce a lot of power. Side note, assuming 800ft/lb at 20rpm would only result in 3HP, my lawn mower makes more. Hope that makes some sense.

Maybe you can think of it this way, the engine is a wrench you pull by hand with a relatively continuous pressure and the impact is the same wrench you are hitting with a hammer. You can get more instant power from the hammer method but only for a moment. Basically its the impact part of the gun that enables it to produce a lot of power. Side note, assuming 800ft/lb at 20rpm would only result in 3HP, my lawn mower makes more. Hope that makes some sense.

#4

Supreme Member

iTrader: (1)

Re: Engine torque vs air wrench torque???

It's the difference between brake power ratings, and steady state power ratings.

To pull on something with constant force is one thing.

To free spin something up to a wild RPM and then bring it to a sudden stop is another thing.

When you spin up the object, you are imparting energy over time, which is then released suddenly - like stretching out a rubber band and letting it go. So you build up 800 Ft/lbs worth of potential energy over a (relatively) longer time period then release it all at once in a giant impact that lasts a fraction of a second.

In an engine you are producing and consuming energy at the same rate. There is no "wind up" to a giant impact. It's just a constant torque.

Walk up to a locked door and place your hands flat against it. Push on it. Can you break it down? Now back up 25 feet, run at the door as fast as you can (building up momentum, and potential energy) and heave your body against the door - breaking it down. Which one imparted more energy to the door? Did your body become stronger in the second case? No - you used built up energy in the form of momentum to greatly magnify your "strength"

GD

To pull on something with constant force is one thing.

To free spin something up to a wild RPM and then bring it to a sudden stop is another thing.

When you spin up the object, you are imparting energy over time, which is then released suddenly - like stretching out a rubber band and letting it go. So you build up 800 Ft/lbs worth of potential energy over a (relatively) longer time period then release it all at once in a giant impact that lasts a fraction of a second.

In an engine you are producing and consuming energy at the same rate. There is no "wind up" to a giant impact. It's just a constant torque.

Walk up to a locked door and place your hands flat against it. Push on it. Can you break it down? Now back up 25 feet, run at the door as fast as you can (building up momentum, and potential energy) and heave your body against the door - breaking it down. Which one imparted more energy to the door? Did your body become stronger in the second case? No - you used built up energy in the form of momentum to greatly magnify your "strength"

GD

#5

Junior Member

Thread Starter

Re: Engine torque vs air Impact wrench torque???

In a side note, when you look at the dyno curves for a motor, the horsepower usually falls off before the torque peaks. This seem odd to me. (5,252 x Horsepower) ÷ rpm = Torque

#6

Supreme Member

iTrader: (1)

Re: Engine torque vs air Impact wrench torque???

Horsepower falls off because of losses in pumping efficiency from engine speeds beyond the capability of the valves and ports to flow air. Turbocharged engines often do not fall off till well after peak torque. They breathe easier because air is going in under pressure.

GD

GD

#7

COTM Editor

iTrader: (22)

Join Date: Mar 2001

Posts: 9,901

Likes: 0

Received 1,855 Likes

on

1,270 Posts

Car: '89 Firebird

Engine: 7.0L

Transmission: T56

Re: Engine torque vs air Impact wrench torque???

Horsepower peaking so low is a choice, not a law. GM used to make sorry, wheezy, pathetic V8 engines in the '80s when our cars were new. It doesn't have to be that way.

Trending Topics

#8

Junior Member

Thread Starter

Re: Engine torque vs air Impact wrench torque???

Those are great explanations, for the HP falling off at higher RPM's. Thank you all... -)

-)

-)

-)

#9

Supreme Member

Re: Engine torque vs air Impact wrench torque???

I was thumbing thru a Harbor freight tool catalog and came across an air impact wrench boasting a torque rating of 800Ft.lbs. which isn't uncommon. How is it that air wrenches can produce more torque than most high performance motors??? In the past I used a 1 inch air impact wrench to loosen the lug nuts on the bud and dayton wheels for tractor-trailers. It had a torque rating of 2500ft-lbs. Although it never seemed hard to handle for me. That is, it never twisted the hell out of my wrists or arms.

Gear reduction is often the key when multiplying torque. You can turn a very small gear very quickly and use it to turn a very large gear, very slowly. to loosen a nut or bolt it only needs to turn slightly. So 5 or 20ft*lbs of torque can be applied to a "large gear" and suddenly 20ft*lb of torque is 400 (20:1 is typical for electric motors fwiw) or 800ft*lbs (40:1)

The starter is a good example. Electric motors either use voltage or current as into torque. The traditional auto starter is a 'current' style I believe. The torque applied is based on current because the higher the current the more of a field is applied, which means more torque. Then there is gear reduction again (as much as it needs can be added) to get the torque high enough to spin an (desired) engine.

more info

http://ctms.engin.umich.edu/CTMS/index.php?example=MotorSpeed§ion=SimulinkModeling

Last edited by Kingtal0n; 01-02-2019 at 03:29 AM.

#11

Supreme Member

Re: Engine torque vs air Impact wrench torque???

Thanks for that.

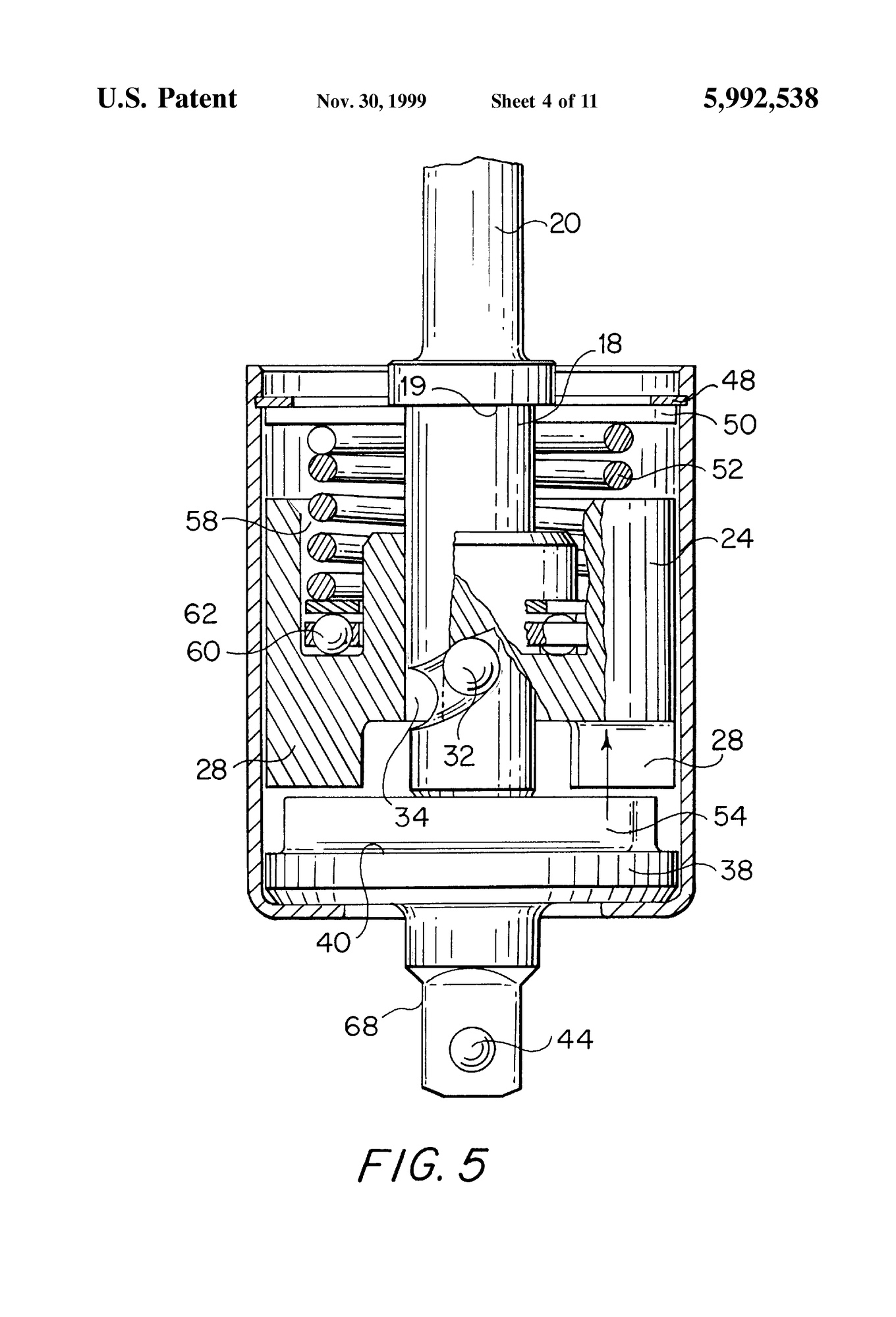

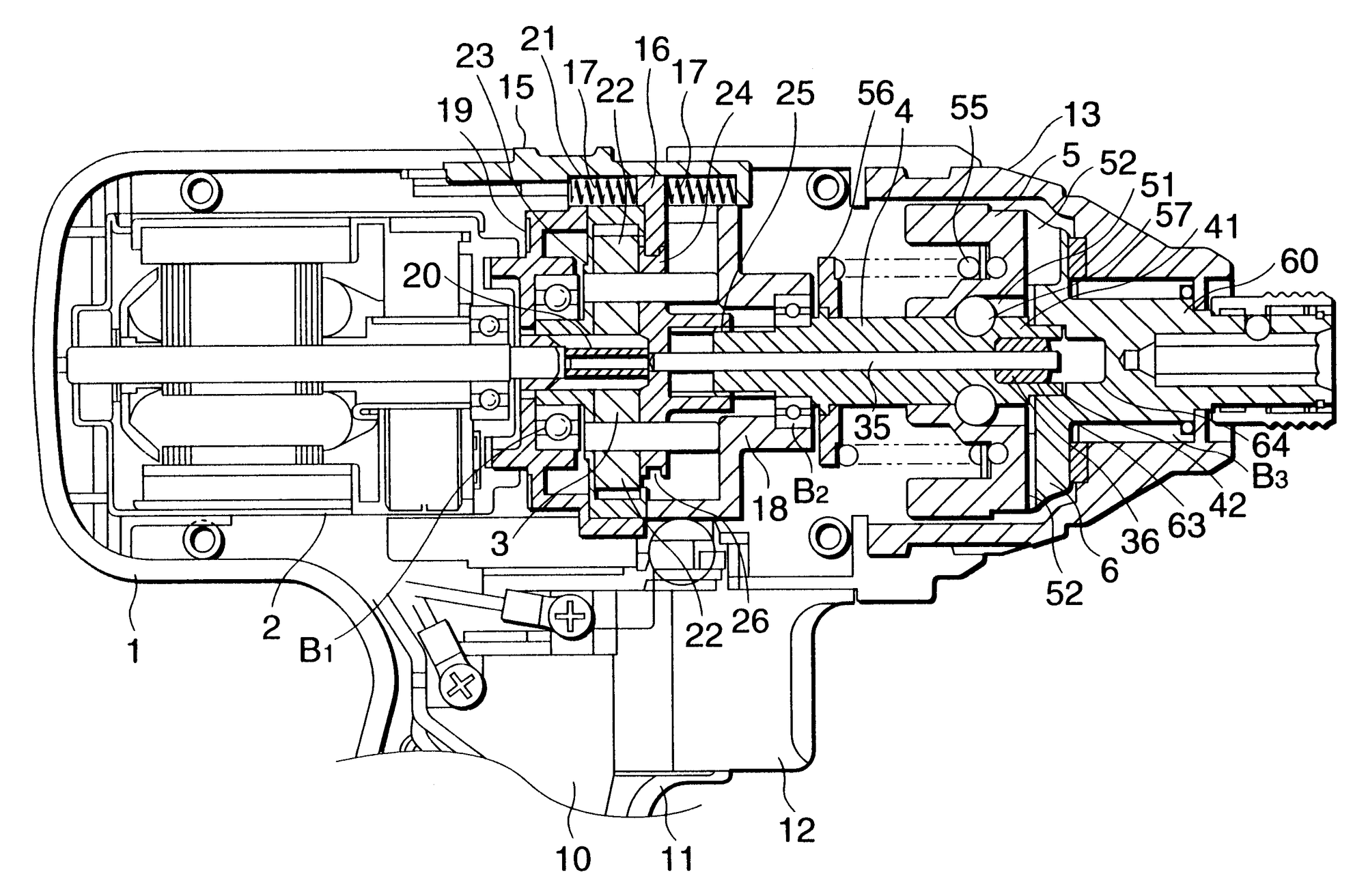

Did some looking into it, some terms seem important "anvil" and "cam", and some drivers have both gear reduction for (non impact use) as well as the rotating impact mechanics.

https://patents.google.com/patent/US7131503B2/en

" An impact driver includes a rotation impact mechanism provided between a motor housed in a housing and an output shaft protruding from the housing so as to transfer a motor torque to the output shaft as well as apply the impact operation to the same in the rotative direction in accordance with increase of a load on the output shaft. "

interesting hammer drill gear reduction

https://patents.google.com/patent/US6550546B2/en

mode selection for impact driver

https://patents.google.com/patent/US20060237205A1/en\

I think this one is an impact driver you can add to a traditional gear reduction drill

https://patents.google.com/patent/US5992538A/en

and finally this one looks like a typical impact (from what I can tell in the pics, although I've never owned one and barely ever used one)

https://patents.google.com/patent/US6457535B1/en

It has a nice description I think

"An impact rotary tool such as an impact wrench and an impact driver is a tool structured such that a hammer, which is connected through a cam to a drive shaft disposed so as to be rotationally driven, is energized by a spring to the side of an anvil disposed on an output shaft, and the anvil is engaged with the hammer in an impact manner by the cam and spring to thereby produce a rotational force; and, when it is used in an operation for tightening a bolt, a nut, and a screw, the impact rotary tool produces only a small reactive force which is given to the hand of an operator, and thus the impact rotary tool provides a high efficiency in the tightening operation."

and decent picture

Never really gave it much thought until now. They don't cover this (at least that I've seen) in any of the traditional mechanics(materials) books, fluids discusses all manner of power and pumps, control covers electric motors, gearing, torque. Advanced mechanics was all about 3-dimensional and higher maths, very little practical application there. Never saw an impact driver in any of them so I wasn't sure. So I am very happy this came up here and I was able to learn something new today.

Last edited by Kingtal0n; 01-02-2019 at 03:49 AM.

#12

Supreme Member

iTrader: (1)

Re: Engine torque vs air Impact wrench torque???

Exactly. Nice pictures. Hard to visualize from the drawings though. Essentially they spin up a weight and the centrifugal force pulls it outward (against a spring) where it slams into the anvil that attaches to the socket. This slows it down and the process starts again. Classically this is of course run by an air motor with centrifugal sliding vanes. Typically there are no gears or gear reductions involved unless it is also a "driver" type tool that has multiple speeds (usually these are planetary, and often multi-stage and multi-speed).

There are, of course, many variations of the design of the impact mechanism. But without fail they do use some type of hammer and nail effect, not a constant torque through a gear train. The idea is to store energy over time, and release it all at once. Thereby imparting the "impact" to the subject.

GD

There are, of course, many variations of the design of the impact mechanism. But without fail they do use some type of hammer and nail effect, not a constant torque through a gear train. The idea is to store energy over time, and release it all at once. Thereby imparting the "impact" to the subject.

GD

Last edited by GeneralDisorder; 01-03-2019 at 01:02 AM.

#13

Supreme Member

Re: Engine torque vs air Impact wrench torque???

Exactly. Nice pictures. Hard to visualize from the drawings though. Essentially they spin up a weight and the centrifugal force pulls it outward (against a spring) where it slams into the anvil that attaches to the socket. This slows it down and the process starts again. Classically this is of course run by an air motor with centrifugal sliding vanes. Typically there are no gears or gear reductions involved unless it is also a "driver" type tool that has multiple speeds (usually these are planetary, and often multi-stage and multi-speed).

There are, of course, many variations of the design of the impact mechanism. But without fail they do use some type of hammer and nail effect, not a constant torque through a gear train. The idea is to store energy over time, and release it all at once. Thereby imparting the "impact" to the subject.

GD

There are, of course, many variations of the design of the impact mechanism. But without fail they do use some type of hammer and nail effect, not a constant torque through a gear train. The idea is to store energy over time, and release it all at once. Thereby imparting the "impact" to the subject.

GD

thanks again

Thread

Thread Starter

Forum

Replies

Last Post