EBL controlled E85 build

#1

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

EBL controlled E85 build

Little background for my vehicle which is -89 G20 van with stock L05 350 TBI. Long (rusty) headers, 70mm plumbing to "turbo" mufflers with H-pipe, and diesel rear parts. Stock injectors, heated O2 in driver side collector, K&N air filter. Comp 1:1.6 intake rockers.

This van stayed in garage for over 9 years, then was quickly built and got through inspection and smoke tests for daily driver. Culprit was new external vacuum referenced FPR which replaced faulty one in TB.

When van was running again, was time to install Comp Cams XE262H cam & lifters. After break-in noticed that stock '7747 ECM was having very hard times with idle which was asking laborious tuning.

So it was time to ease up job by installing EBL. Initially started engine well and had better idle. But had 4+ years old 95E5 fuel which has lost most of BTU's... so had to turn to E85 way early.

Now crappy headers are messing all tuning up. While still planning next headers putting exhaust putty to keep leakage minimum and able to do some tuning by learning and then correcting.

TB has stock 55# injectors and K&N air filter. Baseline FP is 30 psi which is vacuum corrected. In-tank pump is 190L per hour. Spark plugs are now Champion RV12YC (stock were Delco CR43TS).

Basis of my calibration is EBL _11 binary which was converted per XLS method for E85. Also used utility to correct injector base values per 30 psi vacuum referenced FPR.

Attached are some details from my 73th calibration: VE learn corrections from 72th, VE maps.

What bugs me is that there is some lack of throttle response until AE hits. Cruising 50-60 or 80-90 kph in D goes well to lean cruise and works well. But 80-90 kph on OD lacks power, decelerates and then goes rich. Also cold starts are way rich and when engine warms to 60 C has same banging and lack of power.

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

This van stayed in garage for over 9 years, then was quickly built and got through inspection and smoke tests for daily driver. Culprit was new external vacuum referenced FPR which replaced faulty one in TB.

When van was running again, was time to install Comp Cams XE262H cam & lifters. After break-in noticed that stock '7747 ECM was having very hard times with idle which was asking laborious tuning.

So it was time to ease up job by installing EBL. Initially started engine well and had better idle. But had 4+ years old 95E5 fuel which has lost most of BTU's... so had to turn to E85 way early.

Now crappy headers are messing all tuning up. While still planning next headers putting exhaust putty to keep leakage minimum and able to do some tuning by learning and then correcting.

TB has stock 55# injectors and K&N air filter. Baseline FP is 30 psi which is vacuum corrected. In-tank pump is 190L per hour. Spark plugs are now Champion RV12YC (stock were Delco CR43TS).

Basis of my calibration is EBL _11 binary which was converted per XLS method for E85. Also used utility to correct injector base values per 30 psi vacuum referenced FPR.

Attached are some details from my 73th calibration: VE learn corrections from 72th, VE maps.

What bugs me is that there is some lack of throttle response until AE hits. Cruising 50-60 or 80-90 kph in D goes well to lean cruise and works well. But 80-90 kph on OD lacks power, decelerates and then goes rich. Also cold starts are way rich and when engine warms to 60 C has same banging and lack of power.

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

#2

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Some more details: when fixing FPR problem replaced in-tank pump (twice!), fuel filter, external HEI coil, HEI spark driver (died over cam swap!?). Also installed new set of Autolite 26 spark plugs.

As cam is quite radical for stock heads & springs, did tune rev limiter for 4200-4500 rpm. That's just when real power starts to build up...

About headers, I've been tinkering for years to build custom tri-y (4-2-1) headers. As in muscle car era some V8 vehicles had under oil pan cross-over headers why not trying to do most even exhaust plumbing as seen per cylinder. Like this:

As engine fires 1-8-4-3-6-5-7-2 pairing tri-y properly for 180 degree separation is practically impossible. Commercial tri-y headers have primaries for 1-5 and 3-7 joined in left secondary, and 2-4 and 6-8 for right.

I'm thinking of building headers to pair primaries so that 1-7 secondary is paired by under oil pan secondary of 4-6. And same for 3-5 and 2-8. This generates exhaust pulses in exit collectors in 90 degrees.

Playing some with Mez Porting header calculator something like this is to built:

* 15" primaries of 1.824" diameter

* 20" secundaries, 2.399" diameter

* 7.2" collectors, 2.57" diameter.

As this is not easy build, I'm considering to chop current long 4-1 headers to build prototype for verification. Then build real ones from stainless.

As cam is quite radical for stock heads & springs, did tune rev limiter for 4200-4500 rpm. That's just when real power starts to build up...

About headers, I've been tinkering for years to build custom tri-y (4-2-1) headers. As in muscle car era some V8 vehicles had under oil pan cross-over headers why not trying to do most even exhaust plumbing as seen per cylinder. Like this:

As engine fires 1-8-4-3-6-5-7-2 pairing tri-y properly for 180 degree separation is practically impossible. Commercial tri-y headers have primaries for 1-5 and 3-7 joined in left secondary, and 2-4 and 6-8 for right.

I'm thinking of building headers to pair primaries so that 1-7 secondary is paired by under oil pan secondary of 4-6. And same for 3-5 and 2-8. This generates exhaust pulses in exit collectors in 90 degrees.

Playing some with Mez Porting header calculator something like this is to built:

* 15" primaries of 1.824" diameter

* 20" secundaries, 2.399" diameter

* 7.2" collectors, 2.57" diameter.

As this is not easy build, I'm considering to chop current long 4-1 headers to build prototype for verification. Then build real ones from stainless.

#3

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,399

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: EBL controlled E85 build

What bugs me is that there is some lack of throttle response until AE hits. Cruising 50-60 or 80-90 kph in D goes well to lean cruise and works well. But 80-90 kph on OD lacks power, decelerates and then goes rich. Also cold starts are way rich and when engine warms to 60 C has same banging and lack of power.

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

For the rich cold starts, if it is only rich for the first minute or so, work with this table:

Choke - AFR

The values in that table are subtracted from the AFR, so a larger value is richer.

If the engine runs rich through most of the cold operation work with this table:

Open Loop - AFR Multiplier vs CTS

Note the values in the stock table, a more negative number is richer. It is a multiplier to the AFR.

> when engine warms to 60 C has same banging and lack of power.

Is knock being reported by the ECM? If so may need to work on the SA:

SA - Coolant Comp Spark Advance

Note that that table has a bias value, usually 9.84*. So any entry at that value will have no affect on the SA. A value higher then the bias adds SA, a value lower then the bias subtracts SA.

> Also installed new set of Autolite 26 spark plugs.

That plug is on the hot side. Isn't stock a # 24 plug? Or is this done due to the cold climate this time of year? I'd be leery of running a #26 plug.

RBob.

#4

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

The VE appears to be dropping off too quickly as the RPM increases. The cam makes peak HP at about 5K RPM. I also wouldn't use the rev-limiter to prevent he engine from being used in it's power range. A fuel cut is rather harsh and is only intended as a last gasp to save an engine in the event of drive-line breakage or loss of traction.

We have winter and snow on ground here, my tuning is mostly to perfect VE low speed table, only couple of hits in higher table, nothing really meaningful to get those in good order.

As this is daily driver, I'm considering mandatory to get low speed table and other throttle response issues in order.

For the rich cold starts, if it is only rich for the first minute or so, work with this table:

Choke - AFR

The values in that table are subtracted from the AFR, so a larger value is richer.

If the engine runs rich through most of the cold operation work with this table:

Open Loop - AFR Multiplier vs CTS

Note the values in the stock table, a more negative number is richer. It is a multiplier to the AFR.

Choke - AFR

The values in that table are subtracted from the AFR, so a larger value is richer.

If the engine runs rich through most of the cold operation work with this table:

Open Loop - AFR Multiplier vs CTS

Note the values in the stock table, a more negative number is richer. It is a multiplier to the AFR.

> when engine warms to 60 C has same banging and lack of power.

Is knock being reported by the ECM? If so may need to work on the SA:

SA - Coolant Comp Spark Advance

Note that that table has a bias value, usually 9.84*. So any entry at that value will have no affect on the SA. A value higher then the bias adds SA, a value lower then the bias subtracts SA.

Is knock being reported by the ECM? If so may need to work on the SA:

SA - Coolant Comp Spark Advance

Note that that table has a bias value, usually 9.84*. So any entry at that value will have no affect on the SA. A value higher then the bias adds SA, a value lower then the bias subtracts SA.

As Autolite's are almost impossible to find here, and only Champion temp rating was clear enough what's needed I cross-researched stock plug temp and then subtracted three for #12.

I'm yet to check plug color... only hundred or two driving with those to date.

#5

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

About headers, I've been tinkering for years to build custom tri-y (4-2-1) headers...

As engine fires 1-8-4-3-6-5-7-2 pairing tri-y properly for 180 degree separation is practically impossible. Commercial tri-y headers have primaries for 1-5 and 3-7 joined in left secondary, and 2-4 and 6-8 for right.

I'm thinking of building headers to pair primaries so that 1-7 secondary is paired by under oil pan secondary of 4-6. And same for 3-5 and 2-8. This generates exhaust pulses in exit collectors in 90 degrees.

Playing some with Mez Porting header calculator something like this is to built:

* 15" primaries of 1.824" diameter

* 20" secundaries, 2.399" diameter

* 7.2" collectors, 2.57" diameter.

As this is not easy build, I'm considering to chop current long 4-1 headers to build prototype for verification. Then build real ones from stainless.

As engine fires 1-8-4-3-6-5-7-2 pairing tri-y properly for 180 degree separation is practically impossible. Commercial tri-y headers have primaries for 1-5 and 3-7 joined in left secondary, and 2-4 and 6-8 for right.

I'm thinking of building headers to pair primaries so that 1-7 secondary is paired by under oil pan secondary of 4-6. And same for 3-5 and 2-8. This generates exhaust pulses in exit collectors in 90 degrees.

Playing some with Mez Porting header calculator something like this is to built:

* 15" primaries of 1.824" diameter

* 20" secundaries, 2.399" diameter

* 7.2" collectors, 2.57" diameter.

As this is not easy build, I'm considering to chop current long 4-1 headers to build prototype for verification. Then build real ones from stainless.

Right side was pretty tricky to get done properly to avoid brake and fuel lines, (big) starter motor, to get crossover under oil pan just behind subframe.

Missing O2 bungs and plumbing to mufflers. And need to do set of exhaust port gaskets too.

This is prototype built from old rusty long 4-1 header as their collectors were all rotten and messed up my tuning effort hopelessly.

Let's see how well these work out, next version will be built from stainless tubing and J-bends...

#6

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

Little background for my vehicle which is -89 G20 van with stock L05 350 TBI. Long (rusty) headers, 70mm plumbing to "turbo" mufflers with H-pipe, and diesel rear parts. Stock injectors, heated O2 in driver side collector, K&N air filter. Comp 1:1.6 intake rockers.

This van stayed in garage for over 9 years, then was quickly built and got through inspection and smoke tests for daily driver. Culprit was new external vacuum referenced FPR which replaced faulty one in TB.

When van was running again, was time to install Comp Cams XE262H cam & lifters. After break-in noticed that stock '7747 ECM was having very hard times with idle which was asking laborious tuning.

So it was time to ease up job by installing EBL. Initially started engine well and had better idle. But had 4+ years old 95E5 fuel which has lost most of BTU's... so had to turn to E85 way early.

Now crappy headers are messing all tuning up. While still planning next headers putting exhaust putty to keep leakage minimum and able to do some tuning by learning and then correcting.

TB has stock 55# injectors and K&N air filter. Baseline FP is 30 psi which is vacuum corrected. In-tank pump is 190L per hour. Spark plugs are now Champion RV12YC (stock were Delco CR43TS).

Basis of my calibration is EBL _11 binary which was converted per XLS method for E85. Also used utility to correct injector base values per 30 psi vacuum referenced FPR.

Attached are some details from my 73th calibration: VE learn corrections from 72th, VE maps.

What bugs me is that there is some lack of throttle response until AE hits. Cruising 50-60 or 80-90 kph in D goes well to lean cruise and works well. But 80-90 kph on OD lacks power, decelerates and then goes rich. Also cold starts are way rich and when engine warms to 60 C has same banging and lack of power.

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

This van stayed in garage for over 9 years, then was quickly built and got through inspection and smoke tests for daily driver. Culprit was new external vacuum referenced FPR which replaced faulty one in TB.

When van was running again, was time to install Comp Cams XE262H cam & lifters. After break-in noticed that stock '7747 ECM was having very hard times with idle which was asking laborious tuning.

So it was time to ease up job by installing EBL. Initially started engine well and had better idle. But had 4+ years old 95E5 fuel which has lost most of BTU's... so had to turn to E85 way early.

Now crappy headers are messing all tuning up. While still planning next headers putting exhaust putty to keep leakage minimum and able to do some tuning by learning and then correcting.

TB has stock 55# injectors and K&N air filter. Baseline FP is 30 psi which is vacuum corrected. In-tank pump is 190L per hour. Spark plugs are now Champion RV12YC (stock were Delco CR43TS).

Basis of my calibration is EBL _11 binary which was converted per XLS method for E85. Also used utility to correct injector base values per 30 psi vacuum referenced FPR.

Attached are some details from my 73th calibration: VE learn corrections from 72th, VE maps.

What bugs me is that there is some lack of throttle response until AE hits. Cruising 50-60 or 80-90 kph in D goes well to lean cruise and works well. But 80-90 kph on OD lacks power, decelerates and then goes rich. Also cold starts are way rich and when engine warms to 60 C has same banging and lack of power.

I've done some stock ECM tuning but this time likely had little too much changes done prior of doing tuning. EBL has eased up things plenty as did BobR.

Any obvious problems in my VE maps ?

I never have had any luck running champion plugs of any kind in a Chevrolet engine. For me its Delco only. About 10 years ago I swapped my 83 G20 to Champion "Truck" plugs that promised the world about being detonation resistant and running cool. They ran ok for a few weeks, but I ended up chasing poor running for a couple of months before tracing it back to the plugs.

Sounds like your main fuel tables still need work. I also found that sluggish running in OD was somewhat alleviated by entering PE mode around 50-60% TPS.

Stock 350s have 61# injectors, its the 305s that have 55#.

#7

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Three things I see actually....

I never have had any luck running champion plugs of any kind in a Chevrolet engine. For me its Delco only. About 10 years ago I swapped my 83 G20 to Champion "Truck" plugs that promised the world about being detonation resistant and running cool. They ran ok for a few weeks, but I ended up chasing poor running for a couple of months before tracing it back to the plugs.

Sounds like your main fuel tables still need work. I also found that sluggish running in OD was somewhat alleviated by entering PE mode around 50-60% TPS.

Stock 350s have 61# injectors, its the 305s that have 55#.

I never have had any luck running champion plugs of any kind in a Chevrolet engine. For me its Delco only. About 10 years ago I swapped my 83 G20 to Champion "Truck" plugs that promised the world about being detonation resistant and running cool. They ran ok for a few weeks, but I ended up chasing poor running for a couple of months before tracing it back to the plugs.

Sounds like your main fuel tables still need work. I also found that sluggish running in OD was somewhat alleviated by entering PE mode around 50-60% TPS.

Stock 350s have 61# injectors, its the 305s that have 55#.

Yes, my fuel maps are off. Spoiled by leaking exhaust and maybe other problems. Today these new diy headers are put to test as got them installed early this morning...

My 55# injectors are verified from P.N. This L05 was rated (per VIN) 180hp stock. Heads and TBI manifold have been so restrictive that after some 25% throttle nothing happens with heavier use of throttle. I know, ridiculously small but with hopped up FP and helped with vacuum compensation those should be quite OK for about 300 hp.

Anyone machined SBC TB to 2" ? How about bigger butterflies, or where to get them ?

Trending Topics

#8

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

I fully agree about Champion plugs. I've had very bad experiences using those in my young hood in snowmobiles and other 2-stroke engines. I'm considering to test temp rage with these, and then (mail order) proper Delco or Autolite plugs with correct rating.

Yes, my fuel maps are off. Spoiled by leaking exhaust and maybe other problems. Today these new diy headers are put to test as got them installed early this morning...

My 55# injectors are verified from P.N. This L05 was rated (per VIN) 180hp stock. Heads and TBI manifold have been so restrictive that after some 25% throttle nothing happens with heavier use of throttle. I know, ridiculously small but with hopped up FP and helped with vacuum compensation those should be quite OK for about 300 hp.

Anyone machined SBC TB to 2" ? How about bigger butterflies, or where to get them ?

Yes, my fuel maps are off. Spoiled by leaking exhaust and maybe other problems. Today these new diy headers are put to test as got them installed early this morning...

My 55# injectors are verified from P.N. This L05 was rated (per VIN) 180hp stock. Heads and TBI manifold have been so restrictive that after some 25% throttle nothing happens with heavier use of throttle. I know, ridiculously small but with hopped up FP and helped with vacuum compensation those should be quite OK for about 300 hp.

Anyone machined SBC TB to 2" ? How about bigger butterflies, or where to get them ?

Someone must have swapped the 55# injectors into that van or the page you referenced had bad information on it.

I setup my old EBL classice circa 2005ish to run the 305 in the Formula. Stock fuel system was at 11 psi and the stock injectors ran out of fuel at 3,100 rpm.

#9

Re: EBL controlled E85 build

I fully agree about Champion plugs. I've had very bad experiences using those in my young hood in snowmobiles and other 2-stroke engines. I'm considering to test temp rage with these, and then (mail order) proper Delco or Autolite plugs with correct rating.

Yes, my fuel maps are off. Spoiled by leaking exhaust and maybe other problems. Today these new diy headers are put to test as got them installed early this morning...

My 55# injectors are verified from P.N. This L05 was rated (per VIN) 180hp stock. Heads and TBI manifold have been so restrictive that after some 25% throttle nothing happens with heavier use of throttle. I know, ridiculously small but with hopped up FP and helped with vacuum compensation those should be quite OK for about 300 hp.

Anyone machined SBC TB to 2" ? How about bigger butterflies, or where to get them ?

Yes, my fuel maps are off. Spoiled by leaking exhaust and maybe other problems. Today these new diy headers are put to test as got them installed early this morning...

My 55# injectors are verified from P.N. This L05 was rated (per VIN) 180hp stock. Heads and TBI manifold have been so restrictive that after some 25% throttle nothing happens with heavier use of throttle. I know, ridiculously small but with hopped up FP and helped with vacuum compensation those should be quite OK for about 300 hp.

Anyone machined SBC TB to 2" ? How about bigger butterflies, or where to get them ?

#10

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

At 180 hp you are barely touching 2/3 of the stock throttle bodies ~275-300 hp potential.

Someone must have swapped the 55# injectors into that van or the page you referenced had bad information on it.

I setup my old EBL classice circa 2005ish to run the 305 in the Formula. Stock fuel system was at 11 psi and the stock injectors ran out of fuel at 3,100 rpm.

Someone must have swapped the 55# injectors into that van or the page you referenced had bad information on it.

I setup my old EBL classice circa 2005ish to run the 305 in the Formula. Stock fuel system was at 11 psi and the stock injectors ran out of fuel at 3,100 rpm.

I took photos of my injectors which have pn# GM 5235206 * RPD, according to Diy-EFI injector info those are #55 ones.

Good to know TB is good for about 300 hp air flow. My injectors are good for almost same in 30 psi vacuum referenced fpr.

Only heads and stock TBI intake are then limiting its potential. And Champion plugs.

#11

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Without H-tube idle sounds like with 4-1 headers but when revving engine higher it sounds like euro V8. Revs with ease and very even sound. There is acoustic resonance in one narrow rev range, maybe I'll try 20 cent openings to H-tube to lessen it.

What comes to EBL calibration big changes in maps and for better. Still have weak spot in 70-90 map and 1300-1700 rpms and especially if/when/because enters to AE. So I re-started calibration by creating new baseline from _2011 bin, correcting injector data and converting tables for E85.

Run out of inert gas and seems to have couple of minor leaks in older plumbing, and some in under oil pan couplers. Also 3-5 header gasket's leaking. Fix for those and maybe eBay purchase of Innovate WB sensor...

#12

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

As hinted now Innovate LC-1 is installed. It replaced Bosh 3-wire heated NB sensor and simulated NB is wired to ECM and WB to EBL analog channel.

Calibrating is more accurate and less odd variations. Most of dead zone issues are resolved with driving half tank of E85.

Little bit more fine-tuning when engine warm, then more work to get cold start problems and stalling when idling (both neutral and in gear) to better order.

Calibrating is more accurate and less odd variations. Most of dead zone issues are resolved with driving half tank of E85.

Little bit more fine-tuning when engine warm, then more work to get cold start problems and stalling when idling (both neutral and in gear) to better order.

#13

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

As hinted now Innovate LC-1 is installed. It replaced Bosh 3-wire heated NB sensor and simulated NB is wired to ECM and WB to EBL analog channel.

Calibrating is more accurate and less odd variations. Most of dead zone issues are resolved with driving half tank of E85.

Little bit more fine-tuning when engine warm, then more work to get cold start problems and stalling when idling (both neutral and in gear) to better order.

Calibrating is more accurate and less odd variations. Most of dead zone issues are resolved with driving half tank of E85.

Little bit more fine-tuning when engine warm, then more work to get cold start problems and stalling when idling (both neutral and in gear) to better order.

So I restored Bosh 3-wire NB to driver side header and moved LC-1 WB to right side. Added status led and calibration button for LC-1 and toggle switch for EBL NB signal so I can run it both NB and LC-1 simulated NB. And separated heater ground from LC-1 signal ground which is now grounded to where engine's signal ground lead is mounted.

Also created user sensor and used WB ratios and voltages per LC-1 documentation. Now WhatsApp is running engine fairly ok with both NB signals but WB is reporting rich all times.

As I'm puzzled with this, and did free-air WB calibration too, I'm to hook laptop to see how LC-1 thinks about AFR...

#15

Re: EBL controlled E85 build

Yes, that's ridiculous. Maybe it explains why it also had ANLX "stock" calibration for California emissions, in a van imported from Canada...

I took photos of my injectors which have pn# GM 5235206 * RPD, according to Diy-EFI injector info those are #55 ones.

Good to know TB is good for about 300 hp air flow. My injectors are good for almost same in 30 psi vacuum referenced fpr.

Only heads and stock TBI intake are then limiting its potential. And Champion plugs.

I took photos of my injectors which have pn# GM 5235206 * RPD, according to Diy-EFI injector info those are #55 ones.

Good to know TB is good for about 300 hp air flow. My injectors are good for almost same in 30 psi vacuum referenced fpr.

Only heads and stock TBI intake are then limiting its potential. And Champion plugs.

BTW, just because the van came from Canada doesn't mean it spent it whole live there. A lot of cars were made in Canada and sold to the US and vise-versa. A dead give away of where a car was sold to was if the speedometer is in KPH or MPH...

#16

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

diy-efi.org really needs to go away. I am sure it was a great source of information 10+ years ago, but most of it is out of date. Please refer to the document in this post. 5235206's are 61#/hr. Better yet, read the rest of the thread and see how my 68#/hr pound injectors actually flowed @ 74#/hr.

BTW, just because the van came from Canada doesn't mean it spent it whole live there. A lot of cars were made in Canada and sold to the US and vise-versa. A dead give away of where a car was sold to was if the speedometer is in KPH or MPH...

BTW, just because the van came from Canada doesn't mean it spent it whole live there. A lot of cars were made in Canada and sold to the US and vise-versa. A dead give away of where a car was sold to was if the speedometer is in KPH or MPH...

Checked yesterday FPR and it's 30 psi non-running and following manifold vacuum. Also no exhaust (header) leaks anymore.

What comes to origin of this van, it's imported by Finnish person whom ordered it with custom options from factory (likely worked @ Canada, importing then was tax-free).

It's been built from -88 & -89 components and imported to Finland @ -89. Single owner who exchanged it in car retailer to something else. Owned by retailers since for some years until I bought it. Was very cheap

barely was running in cold winter weather.

barely was running in cold winter weather.Wheels & rims were swapped for sure. Windshield wiper pump was stolen. Exhaust was almost rusted away. All chassis joints were dry, rusty and soon done one by one. Had only 46,000 miles in odo.

#17

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Any ideas where that grounding location is in -89 van ? Haven't followed ECU harness to hunt that location yet, between chassis and engine there's quality grounding on top of trans, LC-1 is now grounded there (chassis side of harness).

Haven't measured yet but there is not such big electricity potential difference, from ECU and LC-1 point of view. As lamda sensor grounding is separated.

Had little fun trying to get Innovate apps to work in Ubuntu running Wine and having USB-serial ports yesterday... today continues with Windows-7 laptop...

Haven't measured yet but there is not such big electricity potential difference, from ECU and LC-1 point of view. As lamda sensor grounding is separated.

Had little fun trying to get Innovate apps to work in Ubuntu running Wine and having USB-serial ports yesterday... today continues with Windows-7 laptop...

#18

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Little update as I got Windows laptop to play fair with USB-serial adapter and LC-1... AFR was to 0.1 accuracy same as reported by EBL WhatsUp.

Also converted injectors for 61# and re-started from _2011 baseline. Much better cold AFR and behavior, also learning way much faster, both from BLM and WB.

Also converted injectors for 61# and re-started from _2011 baseline. Much better cold AFR and behavior, also learning way much faster, both from BLM and WB.

#20

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Today was quite progressive for tuning. Not a day to start hunting LC-1 grounding issues, but to study how it really works and get correct signal to EBL.

Haven't found clear procedure how to do it except some hints in LC-1 documentation, so this is how I proceeded:

Using Windows laptop and LC-1 programming utility, changed it to output 1.0 Volts for 7.35 AFR and 4.0 Volts for 22.39 AFR. Then calculated voltage for 14.7 AFR and set that to both voltage fields.

Then to EBL and tuned my "Innovate LC-1" User Device so that started from 1V/7.35 and 4V/22.39 and adding same value to both voltages until EBL was getting solid and constant 14.7 AFR. Was little amazed that it's 1.412 V and 4.412 V.

Then back to LC-1 programmer and set 1 V / 4 V ranges. Now I'm getting reliable WB AFR values to play with, but in much narrower voltage range, not biggie.

Next set my calibration for 128 BLM limits and disables highway mode. Time to hit the road for getting calibration to true ballpark. For everything else than WOT @ 1500-1900 RPM calibration was quickly put to order.

Restored BLM learning and fine-tuned it using normal NB learning. Success !

Haven't found clear procedure how to do it except some hints in LC-1 documentation, so this is how I proceeded:

Using Windows laptop and LC-1 programming utility, changed it to output 1.0 Volts for 7.35 AFR and 4.0 Volts for 22.39 AFR. Then calculated voltage for 14.7 AFR and set that to both voltage fields.

Then to EBL and tuned my "Innovate LC-1" User Device so that started from 1V/7.35 and 4V/22.39 and adding same value to both voltages until EBL was getting solid and constant 14.7 AFR. Was little amazed that it's 1.412 V and 4.412 V.

Then back to LC-1 programmer and set 1 V / 4 V ranges. Now I'm getting reliable WB AFR values to play with, but in much narrower voltage range, not biggie.

Next set my calibration for 128 BLM limits and disables highway mode. Time to hit the road for getting calibration to true ballpark. For everything else than WOT @ 1500-1900 RPM calibration was quickly put to order.

Restored BLM learning and fine-tuned it using normal NB learning. Success !

#21

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Will go through all engine harness and grounding issues. As I recall I've got odd behaviour with stock ECM and calibration, and currently best tune is behaving about same, including all oddities.

#22

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Dug open LC-1 split wire cable and found shielding wire between rubber and shielding wrapping. Soldered wire to it as mine is 6-lead model without green "analog ground" wire, then soldered it and white ground wire to this ground lead going to engine head.

Did plenty of NB calibrating and got it to run pretty decently and responding to throttle better than before.

Why NB ? Of course WB "User Device" needs to be re-checked for voltage shifting. Plan is to widen range by configuring LC-1 to output 0.5 V to 4.5 V and play with EBL to get 14.7:1 ratio right. And M$ laptop is @ work... and if there's ground level difference from WB WhatsUp VE learning gets pretty much "12" values when decelerating or WOT.

I'm also expecting that my injectors are flowing more than 61# as when cold starting, open loop is way rich. Stalls easily when in gear and not moving.

Cold starting has been much of windmilling and 3-4th key-in leads to running engine. I've added 20 counts to minimum IAC counts table to compensate this.

Next step to make EBL to understand LC-1 WB. Then follow carefully cold AFR and maybe use little bigger injector size in EBL_Utility calculation.

#23

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Thanks to discussion in other thread about initial distributor advance I got that thing to start and run way much better than actually ever before. Even cruising 90 kph in overdrive works like a dream and fuel consumption pretty decent.

But, as our spring progresses, I have hard times getting air conditioning to work. I recall testing its basic functionality with stock '7747 while breaking in new cam but now EBL doesn't even see commanded air-cond and compressor is not activated.

I've checked heater switches which seems to work as expected.

Could there be some difference in EBL calibration to listen different input or need to wire command wire to different connector pin ?

But, as our spring progresses, I have hard times getting air conditioning to work. I recall testing its basic functionality with stock '7747 while breaking in new cam but now EBL doesn't even see commanded air-cond and compressor is not activated.

I've checked heater switches which seems to work as expected.

Could there be some difference in EBL calibration to listen different input or need to wire command wire to different connector pin ?

#24

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

Thanks to discussion in other thread about initial distributor advance I got that thing to start and run way much better than actually ever before. Even cruising 90 kph in overdrive works like a dream and fuel consumption pretty decent.

But, as our spring progresses, I have hard times getting air conditioning to work. I recall testing its basic functionality with stock '7747 while breaking in new cam but now EBL doesn't even see commanded air-cond and compressor is not activated.

I've checked heater switches which seems to work as expected.

Could there be some difference in EBL calibration to listen different input or need to wire command wire to different connector pin ?

But, as our spring progresses, I have hard times getting air conditioning to work. I recall testing its basic functionality with stock '7747 while breaking in new cam but now EBL doesn't even see commanded air-cond and compressor is not activated.

I've checked heater switches which seems to work as expected.

Could there be some difference in EBL calibration to listen different input or need to wire command wire to different connector pin ?

#25

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Most likely this bugger has dried up seals in a/c system and not much if any refrigerant is present. Here it's illegal to fill using Freon so I need to work to get all seals and non-compliant rubber parts replaced for modern replacement refrigerant.

#26

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,399

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: EBL controlled E85 build

RBob.

#27

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

Thanks for verifying this. I was little confused as EBL WhatsUp has a/c request and drive indicators... but it might be handy to convert 7747 to control a/c, mostly to disengage compressor on WOT and when cranking.

Most likely this bugger has dried up seals in a/c system and not much if any refrigerant is present. Here it's illegal to fill using Freon so I need to work to get all seals and non-compliant rubber parts replaced for modern replacement refrigerant.

Most likely this bugger has dried up seals in a/c system and not much if any refrigerant is present. Here it's illegal to fill using Freon so I need to work to get all seals and non-compliant rubber parts replaced for modern replacement refrigerant.

#28

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Found this. Awesome method, and not breaking my currently almost non-existent budget.

Thanks Fast355 ! I'll start flushing my current setup and checking compressor asap...

Thanks Fast355 ! I'll start flushing my current setup and checking compressor asap...

#29

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

Found this. Awesome method, and not breaking my currently almost non-existent budget.

Thanks Fast355 ! I'll start flushing my current setup and checking compressor asap...

Thanks Fast355 ! I'll start flushing my current setup and checking compressor asap...

#30

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Getting parts is no problems but where to get a kit like "ATD AC Bag Kit" with reasonable shipping cost is more problematic. As is to find r152a "canned air" spray bottles...

#31

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

A/C stuff is just not available for non-professionals in Europe, and US sellers aren't typically shipping here. Ebay was also pretty much dead end.

I'm only short of Air Duster (r152a) cans, PAG oil and R12 -> R134a adapter.

This weekend will disconnect, check, clean and lubricate compressor. And mail-order orifice and dryer, those are tad too expensive here.

#32

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Some update for topic too. Finally had enough time to remove TBI for hunting down 0 IAC count while idling warm and pretty severe vacuum leak. TBI manifold gasket had totally collapsed in between bores and IAC passages.

Now with new gasget and PCV there is decent idle, way more constant NB (in left header) and WB (in right) readings and good idle. Runs and goes better, consumes less E85.

Pulling mobile camper is now lighter than was normal highway driving without trailers prior to cam swap and E85 conversion. It's XE262H cam and custom headers, and of course EBL and its lean mode.

Now with new gasget and PCV there is decent idle, way more constant NB (in left header) and WB (in right) readings and good idle. Runs and goes better, consumes less E85.

Pulling mobile camper is now lighter than was normal highway driving without trailers prior to cam swap and E85 conversion. It's XE262H cam and custom headers, and of course EBL and its lean mode.

#33

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

After getting tuning to about working shape this is how those plugs looked like:

Last time when checked coloring was about same. I've had hard times searching proper info about what plug temp is correct for E85 and how to interpret that from plugs I would appreciate experienced opinion.

As my next step will be mail-ordering better quality plugs preferably in correct heat range.

My custom headers have been working great. Unfortunately E85 and its exhaust moisture rusted away internals of the mufflers and now I need to seek stainless mufflers. I'm planning to replace those to old plumbing to see how well it works and do I need H-tubing to damp resonation.

Last time when mufflers were about OK ignition base timing was so much off that whole beast was rattling and producing odd noises. After fixing timing it went way quieter... until mufflers gave up.

Last edited by mhelander; 11-05-2013 at 02:13 AM.

#34

Junior Member

Join Date: Aug 2012

Location: Iowa City, IA

Posts: 40

Likes: 0

Received 1 Like

on

1 Post

Car: 94 C1500

Engine: SBC 355

Transmission: 4L60E 2800 Vigilante Convertor

Axle/Gears: 14 Bolt SF 3:73 Posi

Re: EBL controlled E85 build

I just tried to switch my truck over to E85, but I couldn't keep enough fuel at WOT. I still have some E85 in the tank as this is not my daily driver; I was also having idle stalling and on my last drive in 45 F ambient temps. To solve this for the most part I changed all the values in Open Loop AFR vs RPM & VAC (Vac) 80-40 (RPM) 0-3200 to 9.2. This really helped to fix lean stumbles that I was getting. This could be refined, I am just working the gas out that is still in there. I will say if I ever switch to MPI I will defiantly switch back to E85 with a blower the truck seamed to run better and had more power.

#35

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

So after little over week of chopping, TIG-welding and fitting this is how headers turned out:

<snip>

This is prototype built from old rusty long 4-1 header as their collectors were all rotten and messed up my tuning effort hopelessly.

Let's see how well these work out, next version will be built from stainless tubing and J-bends...

<snip>

This is prototype built from old rusty long 4-1 header as their collectors were all rotten and messed up my tuning effort hopelessly.

Let's see how well these work out, next version will be built from stainless tubing and J-bends...

Next steps are to figure out where to order stainless arcs, tubing and flanges for final version of these headers. And 2.5" plumbing from headers through mufflers. Hard to get proper stuff from European continent...

.

.

#36

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

H-pipe removed all resonances sans Super 44 groan when throttling harder.

Run some more learning using NB and highway mode disabled. Big improvements, especially with light throttle, cold starting and typical riding in city streets. Need to do plenty of higher load learning or dyno time to get all maps better.

Anyways this is now behaving better than ever before, including stock HW & tune. Should have easy yearly inspections and passing emissions tests.

Run some more learning using NB and highway mode disabled. Big improvements, especially with light throttle, cold starting and typical riding in city streets. Need to do plenty of higher load learning or dyno time to get all maps better.

Anyways this is now behaving better than ever before, including stock HW & tune. Should have easy yearly inspections and passing emissions tests.

#37

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

This van has been running quite nicely over the summer. Now weathers are about freezing and there is occasional idle stalling. I'm suspecting that Champion RV12YC plugs are causing mis-firing.

After getting tuning to about working shape this is how those plugs looked like:

Last time when checked coloring was about same. I've had hard times searching proper info about what plug temp is correct for E85 and how to interpret that from plugs I would appreciate experienced opinion.

After getting tuning to about working shape this is how those plugs looked like:

Last time when checked coloring was about same. I've had hard times searching proper info about what plug temp is correct for E85 and how to interpret that from plugs I would appreciate experienced opinion.

Cleaned and briefly lubricated K&N air filter and then took torch and checked injectors. Left side injector was dripping when fuel lines were pressurized, even without wires connected. This will definitely cause issues to EBL...

Then started pulling out plugs and that's how those looked:

From left 7-5-3-1 and 2-4-6-8

Seems that dripping left injector caused carbon build-up to half of plugs because of stock dual plane TBI manifold. Other half are in even condition, not sure but maybe my guesswork for heat range was good enough.

These plugs are out and replaced by too warm Autolite 25 plugs. Dropped FP from 30 to 15 PSI and fixed injector constants table and did some VE learning which was changed dramatically.

Seems that it needs now new injectors and definitely not 61# as now but BBC injectors for sure. Hopefully passes smoke tests with these fix-ups.

#38

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,399

Likes: 0

Received 215 Likes

on

201 Posts

Car: check

Engine: check

Transmission: check

Re: EBL controlled E85 build

Good to hear from you again. Some times a dripping injector is caused by a bad lower o-ring. Let us know how it works out.

RBob.

RBob.

#39

Supreme Member

iTrader: (2)

Join Date: Jan 2005

Location: Hurst, Texas

Posts: 9,969

Received 379 Likes

on

323 Posts

Car: 1983 G20 Chevy

Engine: 305 TPI

Transmission: 4L60

Axle/Gears: 14 bolt with 3.07 gears

Re: EBL controlled E85 build

Saga continues, this time to see what can be done to pass failed inspection smoke test. Failed in excess remaining carbon, otherwise good lambda and inspector was happy.

Cleaned and briefly lubricated K&N air filter and then took torch and checked injectors. Left side injector was dripping when fuel lines were pressurized, even without wires connected. This will definitely cause issues to EBL...

Then started pulling out plugs and that's how those looked:

From left 7-5-3-1 and 2-4-6-8

Seems that dripping left injector caused carbon build-up to half of plugs because of stock dual plane TBI manifold. Other half are in even condition, not sure but maybe my guesswork for heat range was good enough.

These plugs are out and replaced by too warm Autolite 25 plugs. Dropped FP from 30 to 15 PSI and fixed injector constants table and did some VE learning which was changed dramatically.

Seems that it needs now new injectors and definitely not 61# as now but BBC injectors for sure. Hopefully passes smoke tests with these fix-ups.

Cleaned and briefly lubricated K&N air filter and then took torch and checked injectors. Left side injector was dripping when fuel lines were pressurized, even without wires connected. This will definitely cause issues to EBL...

Then started pulling out plugs and that's how those looked:

From left 7-5-3-1 and 2-4-6-8

Seems that dripping left injector caused carbon build-up to half of plugs because of stock dual plane TBI manifold. Other half are in even condition, not sure but maybe my guesswork for heat range was good enough.

These plugs are out and replaced by too warm Autolite 25 plugs. Dropped FP from 30 to 15 PSI and fixed injector constants table and did some VE learning which was changed dramatically.

Seems that it needs now new injectors and definitely not 61# as now but BBC injectors for sure. Hopefully passes smoke tests with these fix-ups.

There is a very good chance your leaking injector is a leaking lower o-ring.

Since the alcohol burns so much cooler I would look at trying to find a 205*F thermostat for the beast.

Also if you can blow the thing out really well with some good throttle use and keep the engine running before the test. For cleaner emissions the chevy engines like to be HOT. For emissions tests I had a chip that had the timing about 8* retarded from normal, ran a leaner air/fuel ratio, and had the electric cooling fan set to turn on at 228*F. My TBI and TPI setup both easily passed with this setup after baking the cat with some wide open throttle runs up the on-ramp.

#40

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

.

.Thanks for excellent tip, RBob ! It's been long time since put TBI to pieces last time so forgot those o-rings. No time to order TBI rebuild kit as those aren't likely available locally. I might be lucky that one of these will fit:

. I'm preferring US-English but my head works better with (IT-) technical vocabulary than more common language.

. I'm preferring US-English but my head works better with (IT-) technical vocabulary than more common language.Current thermostat is 90C, 205F is about 96C which might be good for ethanol burning. Currently WhatsUp reports 89..93C coolant temps in all operating conditions. Ethanol use puts definitely way less thermal stress to cooling system, compared to past. Had cardboards between evaporator and radiator to warm up faster, newer run hot even above freezing which was common before ethanol.

My engine and heads have very sharp edge when going too hot, never experienced so oddly behaving engine after that. I had to drive it once back home some 2 miles away without serpentine belt in -10C, alternator seized. It took three short laps, few hours to engine cool properly to get it back to warm garage...

For emissions tests I had a chip that had the timing about 8* retarded from normal, ran a leaner air/fuel ratio, and had the electric cooling fan set to turn on at 228*F. My TBI and TPI setup both easily passed with this setup after baking the cat with some wide open throttle runs up the on-ramp.

#41

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Good news, smoke test passed with ease. Before it drive van to get high operating temps, then removed air filter cap and checked that faulty left side doesn't drip.

Next weekend to really fix using fresh o-rings. Or order new BBC matched injectors and gasket kit.

Thanks for tip, life is good and all time learning...

Next weekend to really fix using fresh o-rings. Or order new BBC matched injectors and gasket kit.

Thanks for tip, life is good and all time learning...

#42

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Pulled off air filter cover and yes, left injector isn't spraying. Pulled it out and it was squashed lower o-ring that caused dripping. Upper o-ring was kind of expanded, too big and hardly got it back where it belongs. Very likely either 25 years old factory seals, or ethanol issue.

But after re-assembling with pristine o-ring and no leaks, injector isn't firing. Swapped its connector to right injector which works. Then measured coils and right is just some ohms, left is about 1000 or more ohms. That injector is gone.

Now I'm going to order BBC matching injectors, targeted for 400-450 hp. Any suggestions for brand, seller and rating ?

And if any Finnish TBI people, especially from Oulu are following this, would have use for one or pair of 61# leftover injectors while new ones are on their way.

#43

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Both are available in ebay but either rebuilt or reburbished. Some vendors advertise matching pairs and none lists what has been pressure where ratings are done. Seems all ebay sellers are shipping to Europe which is typically hassle and very expensive from Jegs and Summit etc.

One is http://www.ebay.com/itm/201094901870?item=201094901870 from "silvershot_platinum" but no part#. Another is http://www.ebay.com/itm/200783991097?item=200783991097 from "e.performance.parts" and part# is 17084304.

Hopping up that high from 61# @ 30psi is big and I'm little worried what happens to fuel atomization in idle because of way shorter pulses and thus passing of emissions inspection. Also it seems that some TBI injectors are good for 70psi but that's rare and likely requires bunch of injectors and testing for matching pair.

I've sent questions about max pressure of those two injector sellers, let's see...

#44

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Those injector and pressure calculations were little high. Correct formula is, I think:

450 hp * 0.45 = 202.5

202.5 / 0.85 = 238.24

gas to E85 multiplication 238.24 * 1.3 = 309.71

309.71 / 2 = 154.85 pounds per hour per injector

(154.85 / 81)^2 * 13 = 47.51 psi

(154.85 / 90)^2 * 13 = 38.49 psi

Seems 90# is the right one. Pressure is likely tolerable, huh.

450 hp * 0.45 = 202.5

202.5 / 0.85 = 238.24

gas to E85 multiplication 238.24 * 1.3 = 309.71

309.71 / 2 = 154.85 pounds per hour per injector

(154.85 / 81)^2 * 13 = 47.51 psi

(154.85 / 90)^2 * 13 = 38.49 psi

Seems 90# is the right one. Pressure is likely tolerable, huh.

#45

Senior Member

Join Date: Oct 2006

Location: California

Posts: 827

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Chevy Camaro RS

Engine: L30 TBI 5.0L Vortec

Transmission: 700R4

Axle/Gears: Stock

Those injector and pressure calculations were little high. Correct formula is, I think:

450 hp * 0.45 = 202.5

202.5 / 0.85 = 238.24

gas to E85 multiplication 238.24 * 1.3 = 309.71

309.71 / 2 = 154.85 pounds per hour per injector

(154.85 / 81)^2 * 13 = 47.51 psi

(154.85 / 90)^2 * 13 = 38.49 psi

Seems 90# is the right one. Pressure is likely tolerable, huh.

450 hp * 0.45 = 202.5

202.5 / 0.85 = 238.24

gas to E85 multiplication 238.24 * 1.3 = 309.71

309.71 / 2 = 154.85 pounds per hour per injector

(154.85 / 81)^2 * 13 = 47.51 psi

(154.85 / 90)^2 * 13 = 38.49 psi

Seems 90# is the right one. Pressure is likely tolerable, huh.

#46

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

That's likely true. 80# should be fair as rated for 13 psi and Rochester pn 17084304 for 90-93 BBC TBI. It'll be likely enough big for my intended use.

#47

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

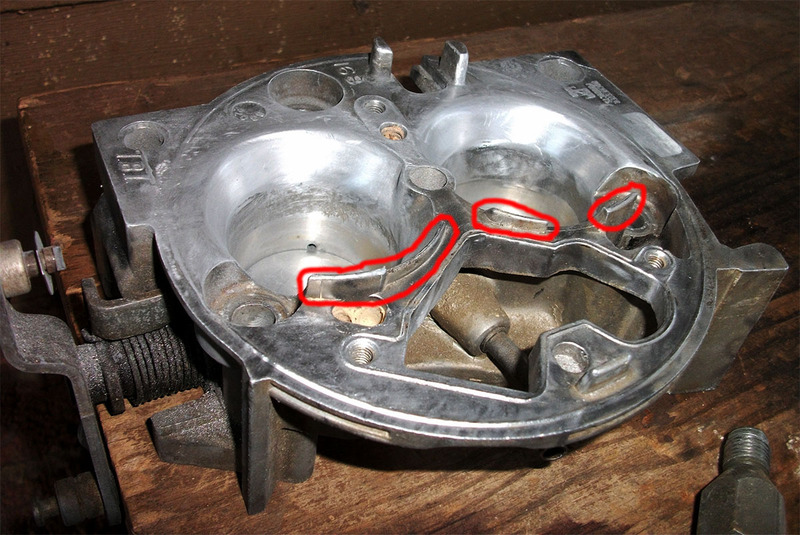

Went over to check his inventory and indeed, there was both old style (TP sensor and idle air passage) and new style TBI's. Immediate realized that this is my opportunity to do planned porting to body and injector pod so pushed my luck with injectors went home with old style TBI.

Good news that both injectors squirt properly. Bad news that those are from Astro Van and 45#, and capable to work max 20 psi pressures. That gives me 210 hp with gas and maybe stock hp with E85.

Next step to purchase 80# or 90# injectors. Both ebay sellers responded so I'll continue dialog until 80# @ 40 psi or 90# @ 35..40 psi matching and pressure verified pair is found. Meanwhile start cleaning and porting of spare TBI, it'll also get FPR blocked.

#48

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Using carbide drill file and air grinder milled off also lower part of left rigde and all the way up to left bolt hole but left about 5mm of the ridge there, same for right side CCW from bolt hole.

While at it maybe shave throttle shaft for both bores, I got little carried away and grinded little too much out, partially blame for poor lightning. Other bore has less than 1mm left and thus shaft rolls because of uneven left/right spring tension and blades seat to idle little uneven and some more for WOT.

As there is some play in shaft, and throttle body is not as good in general as my factory installed one, I'm considering this prototype try-out. It gives me more time to get factory one bored to 50mm and do porting more carefully.

Tried to move FPR blocking plate and gasket (cut out from factory diaphragm) to new assembly which was ported for better flow, but it was leaking. So time to do new better and thicker plate from 3mm 6xxx aluminium and cut new gasket from spare diaphragm. No leaks.

I've completed deal for 17084304 injectors which are refurbished and matched flow for 90 ppm, together with injector gasket kit and pod spacer. When installed started to drip when pressure past 50 psi but when lower, no issues. Good to go.

FPR is set for 15 psi sans vacuum. Couple of re-calibration drives done and power is back. Might have some more than when having non-ported throttle body and working 61# injectors. Idle is good and stable but IAC count is mostly zero, throttle shaft & blades are leaking I assume.

Next steps are to do "salad bowl" mod for air cleaner & spacer. Then put factory throttle body ready for installing with spacer on top of Edelbrock Performer RPM intake & SD8060A heads I've dreamed over decade for this.

Also on their way are NGK BPR6FS spark plugs to replace currently installed Autolite 25 set. I'll drive little more when tuning is now better to check Autolites for even fuel distribution (than before with leaking injector and Champion RV12YC plugs). Heat range is guesswork for me especially with E85 but let's see how it works out.

#49

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Cast quality was much better in this factory TBI than one from V6 Astro... also this time spent my time better with throttle axle's material removal.

Seems my guesswork played nice, fit was just right:

And now there's way more path for air to travel past injector pod:

Installed. While swapping out Autolite plugs #3 was oily and has excess carbon buildup. Soon to check how NGK plugs look after some driving.

#50

Junior Member

Thread Starter

Join Date: Mar 2010

Location: Oulu, Finland

Posts: 54

Likes: 0

Received 0 Likes

on

0 Posts

Car: Chevy G20 van

Engine: L05 350 TBI

Transmission: TH700

Re: EBL controlled E85 build

Whatta week. Plenty of searching to find all required stuff. Now I have professional A/C meter & hose set. Can adapter, O-rings and air vacuum pump are on their way.

A/C stuff is just not available for non-professionals in Europe, and US sellers aren't typically shipping here. Ebay was also pretty much dead end.

I'm only short of Air Duster (r152a) cans, PAG oil and R12 -> R134a adapter.

This weekend will disconnect, check, clean and lubricate compressor. And mail-order orifice and dryer, those are tad too expensive here.

A/C stuff is just not available for non-professionals in Europe, and US sellers aren't typically shipping here. Ebay was also pretty much dead end.

I'm only short of Air Duster (r152a) cans, PAG oil and R12 -> R134a adapter.

This weekend will disconnect, check, clean and lubricate compressor. And mail-order orifice and dryer, those are tad too expensive here.

After consulting local truck cooling shop (tried to borrow R12 pressure side fitting) they confirmed that it's possible to fill coolant from dryer side too, it just takes little longer.

Did plenty of calculations about how many Air Duster cans are needed, started from two but eventually it needed four to run compressor constantly or over 30 seconds in +25..30 C temperatures.

That was done early summer and timing was right, we've had exceptionally warm summer, over 60 days were over +25C and while driving mostly temps were +29 or more. Cooling is fine, compressor runs little rough and I need to put EBL control in place.