DIS options for HEI

#1

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

DIS options for HEI

I am looking at differnt options to convert from HEI to DIS ( multiple coils and no distributor ).

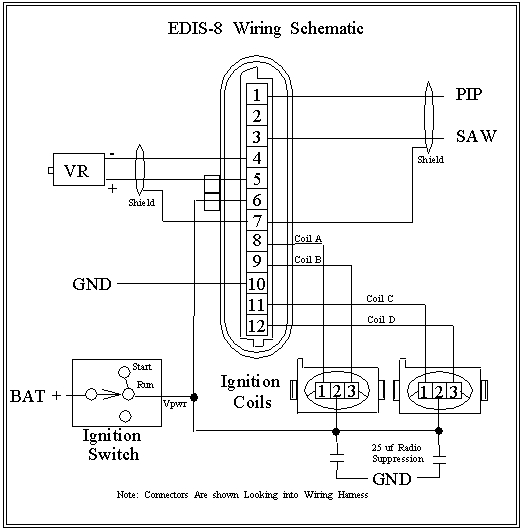

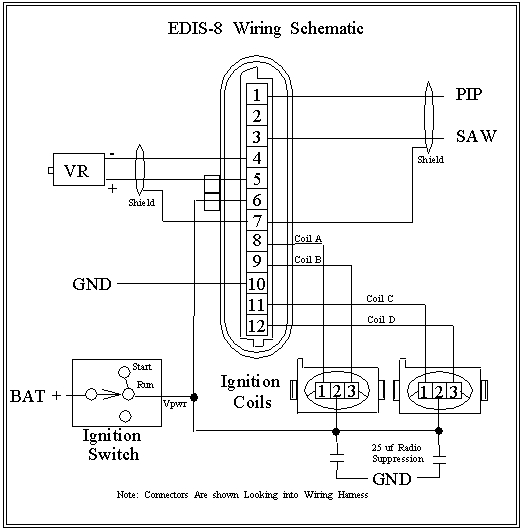

The Ford EDIS8 is an interesting option.

http://www.bgsoflex.com/mjl/mjl_edis_summary.html

It connects to a crank trigger wheel and has 4 coil drivers for waste spark on an 8 cylinder engine. Like the HEI it will use a fixed timing if disconnected from the ECM. It has a tach output (PIP) to the ECM and a spark timing input (SAW). The differance compared to the HEI is that the spark timing signal is a PWM signal where a shorter pulse is more advance. All the actual spark timing is internal in the EDIS. The ECM does not even have to send a PWM pulse for every spark.

Degrees Width(us)

10 1280

20 1024

25 896

30 768

40 512

50 256

55 128

The problem would be to convert the ECM 'timed' signal to a PWM signal. This 'converter' would need two digital inputs, tach reference from EDIS and EST signal from the ECM. From the time differance between these signals the desired timing could be calculated and a PWM pulse sent to the EDIS.

Has anyone done something similar?

With a 'black box' like that with a HEI connector on one side and an EDIS connector on the other side, DIS would be 'plug and play' using OEM stuff for all the rest. Disconnecting the EST cable would result in a fixed timing just like when using the HEI.

I am interested in other options too, but for some reson I like this idea.

The Ford EDIS8 is an interesting option.

http://www.bgsoflex.com/mjl/mjl_edis_summary.html

It connects to a crank trigger wheel and has 4 coil drivers for waste spark on an 8 cylinder engine. Like the HEI it will use a fixed timing if disconnected from the ECM. It has a tach output (PIP) to the ECM and a spark timing input (SAW). The differance compared to the HEI is that the spark timing signal is a PWM signal where a shorter pulse is more advance. All the actual spark timing is internal in the EDIS. The ECM does not even have to send a PWM pulse for every spark.

Degrees Width(us)

10 1280

20 1024

25 896

30 768

40 512

50 256

55 128

The problem would be to convert the ECM 'timed' signal to a PWM signal. This 'converter' would need two digital inputs, tach reference from EDIS and EST signal from the ECM. From the time differance between these signals the desired timing could be calculated and a PWM pulse sent to the EDIS.

Has anyone done something similar?

With a 'black box' like that with a HEI connector on one side and an EDIS connector on the other side, DIS would be 'plug and play' using OEM stuff for all the rest. Disconnecting the EST cable would result in a fixed timing just like when using the HEI.

I am interested in other options too, but for some reson I like this idea.

Last edited by JoBy; 10-22-2004 at 06:43 AM.

#2

Member

Join Date: Jan 2003

Location: Lee County, AL

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 Z28

Engine: 383 Single Plane EFI-NOW RUNNING!

Transmission: T56

Axle/Gears: Not there yet...

Might look at the eDist. It'll take the EST out from your ECM directly. It's what I'm gonna use once I get my crank trigger setup going and get an MSD cam sensor here. I have the crank trigger, eDist box and all the wiring for the coil near plug setup plus the 8 coils & brackets from a vortec truck V8; just need some time to spend on it.

http://www.fuelairspark.com/Informat.../FS2001/12.pdf

http://www.fuelairspark.com/Informat.../FS2001/12.pdf

#3

Senior Member

Join Date: Oct 1999

Posts: 6,621

Likes: 0

Received 1 Like

on

1 Post

Car: 91 Red Sled

Axle/Gears: 10bolt Richmond 3.73 Torsen

I wish somebody would come up with the edis stuff because it's a hell of a lot more affordable than getting 8 GM coils (build in igniters), the $300 eDist, crank position signal, cam position signal, and whatever else it takes to get the cam sensor installed in the old dizzy housing.

You're talking around $500 for an ignition system where as the EDIS is in every Ford car in every junkyard right now. I even have a v8 sitting in my driveway that I can grab parts from... just would make it a whole lot nicer than the already really nice (but costly) eDist.

You're talking around $500 for an ignition system where as the EDIS is in every Ford car in every junkyard right now. I even have a v8 sitting in my driveway that I can grab parts from... just would make it a whole lot nicer than the already really nice (but costly) eDist.

#4

Member

Join Date: Jan 2003

Location: Lee County, AL

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 Z28

Engine: 383 Single Plane EFI-NOW RUNNING!

Transmission: T56

Axle/Gears: Not there yet...

I agree that the Edist setup is a little pricey, and had I not been able to get killer deals on the stuff it would still be just a dream. I got a new Edist box, wiring and a new crank trigger from one ebay auction for $250.00. Then later I found the Vortec coils, harnesses and brackets on ebay for $100.00. So, that ain't too bad. MSD makes a dissy plug with a cam sensor built in for about $116.00, a little steep but it will look real nice and with the deals I've gotten on the other stuff it doesn't seem too bad. With the deals I've gotten I'm in for about the same as a complete top of the line conventional ignition. I can't wait to get it working!!

That F*rd thing would be a great alternative if it could easily be made to work.................

That F*rd thing would be a great alternative if it could easily be made to work.................

#5

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

This is the best HEI module description that I have found.

The signal from the Pick-Up Coil goes directly to the ignition coil when the by-pass signal is active. The same signal is the RPM signal to the ECM. By comparing that pulse to the EST signal the desired spark advance from the ECM could be measured.

The signal from the Pick-Up Coil goes directly to the ignition coil when the by-pass signal is active. The same signal is the RPM signal to the ECM. By comparing that pulse to the EST signal the desired spark advance from the ECM could be measured.

#6

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Running a EDIS system with a GM ECM looks rather straight forward. The PIP signal is the Ref+ input to the ECM (DRPs). The ECM will use this to calculate RPM and to control the EST out.

The EST out is the SAW signal to the EDIS. Re-code the dwell and SA routine to output a width instead of actual dwell/fire times and its a done deal. Will also need to disable the code 42 BYPASS/EST lockout.

It is actually easier to do the PW code then the current dwell/fire code. The ECM already syncs the EST to the DRP (Ref+).

RBob.

The EST out is the SAW signal to the EDIS. Re-code the dwell and SA routine to output a width instead of actual dwell/fire times and its a done deal. Will also need to disable the code 42 BYPASS/EST lockout.

It is actually easier to do the PW code then the current dwell/fire code. The ECM already syncs the EST to the DRP (Ref+).

RBob.

#7

Supreme Member

Join Date: Aug 2001

Location: Costal Alabama

Posts: 2,136

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Iroc-Z

Engine: 350, ZZ4 equivalent

Transmission: Pro-Built Road Race 700R4

Axle/Gears: 3.23 Dana 44

JoBy,

Make sure you also take a look at these threads:

https://www.thirdgen.org/techbb2/sho...hreadid=193531

http://www.jpteck.com/

https://www.thirdgen.org/techbb2/sho...hreadid=239672

https://www.thirdgen.org/techbb2/sho...hreadid=219089

I really wish someone would figure out a cheap way to make this work. I am dieing to ditch the dizzy.

Make sure you also take a look at these threads:

https://www.thirdgen.org/techbb2/sho...hreadid=193531

http://www.jpteck.com/

https://www.thirdgen.org/techbb2/sho...hreadid=239672

https://www.thirdgen.org/techbb2/sho...hreadid=219089

I really wish someone would figure out a cheap way to make this work. I am dieing to ditch the dizzy.

Trending Topics

#8

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

What are the facts about the HEI ignition module?

Does it use a fixed dwell time? I think it does. How long?

Does the reference signal from the HEI to ECM occur at the same crank degree ( 6 before tdc ) regardless of RPM?

I assume that the ECM has to compensate for the increasing effect of the dwell time at higher RPM.

Assume that the dwell time in the HEI ingition module is fixed at 2mS.

At 1000 RPM one crank revolution takes 60mS. One spark will fire every 15mS. 2mS dwell is 12 crank degrees.

At 6000 RPM one crank revolution takes 10mS. One spark will fire every 2.5mS. 2mS dwell is 72 degrees.

At 1000 RPM the ECM must fire 12 degrees before the desired timing to compensate for 2mS dwell time.

At 6000 RPM the ECM must fire 72 degrees before the desired timing to compensate for 2mS dwell time.

Using an ignition module with a different dwell time would have a major effect on the timing.

Could the 'signal converter' in the HEI ignition module have some type of dwell / RPM compensation?

Does it use a fixed dwell time? I think it does. How long?

Does the reference signal from the HEI to ECM occur at the same crank degree ( 6 before tdc ) regardless of RPM?

I assume that the ECM has to compensate for the increasing effect of the dwell time at higher RPM.

Assume that the dwell time in the HEI ingition module is fixed at 2mS.

At 1000 RPM one crank revolution takes 60mS. One spark will fire every 15mS. 2mS dwell is 12 crank degrees.

At 6000 RPM one crank revolution takes 10mS. One spark will fire every 2.5mS. 2mS dwell is 72 degrees.

At 1000 RPM the ECM must fire 12 degrees before the desired timing to compensate for 2mS dwell time.

At 6000 RPM the ECM must fire 72 degrees before the desired timing to compensate for 2mS dwell time.

Using an ignition module with a different dwell time would have a major effect on the timing.

Could the 'signal converter' in the HEI ignition module have some type of dwell / RPM compensation?

Last edited by JoBy; 10-26-2004 at 03:45 PM.

#9

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Originally posted by JoBy

What are the facts about the HEI ignition module?

1) Does it use a fixed dwell time? I think it does. How long?

2) Does the reference signal from the HEI to ECM occur at the same crank degree ( 6 before tdc ) regardless of RPM?

3) I assume that the ECM has to compensate for the increasing effect of the dwell time at higher RPM.

4) Assume that the dwell time in the HEI ingition module is fixed at 2mS.

5) At 1000 RPM one crank revolution takes 60mS. One spark will fire every 15mS. 2mS dwell is 12 crank degrees.

6) At 6000 RPM one crank revolution takes 10mS. One spark will fire every 2.5mS. 2mS dwell is 72 degrees.

7) At 1000 RPM the ECM must fire 12 degrees before the desired timing to compensate for 2mS dwell time.

8) At 6000 RPM the ECM must fire 72 degrees before the desired timing to compensate for 2mS dwell time.

9) Using an ignition module with a different dwell time would have a major effect on the timing.

10) Could the 'signal converter' in the HEI ignition module have some type of dwell / RPM compensation?

What are the facts about the HEI ignition module?

1) Does it use a fixed dwell time? I think it does. How long?

2) Does the reference signal from the HEI to ECM occur at the same crank degree ( 6 before tdc ) regardless of RPM?

3) I assume that the ECM has to compensate for the increasing effect of the dwell time at higher RPM.

4) Assume that the dwell time in the HEI ingition module is fixed at 2mS.

5) At 1000 RPM one crank revolution takes 60mS. One spark will fire every 15mS. 2mS dwell is 12 crank degrees.

6) At 6000 RPM one crank revolution takes 10mS. One spark will fire every 2.5mS. 2mS dwell is 72 degrees.

7) At 1000 RPM the ECM must fire 12 degrees before the desired timing to compensate for 2mS dwell time.

8) At 6000 RPM the ECM must fire 72 degrees before the desired timing to compensate for 2mS dwell time.

9) Using an ignition module with a different dwell time would have a major effect on the timing.

10) Could the 'signal converter' in the HEI ignition module have some type of dwell / RPM compensation?

1) No, not a fixed dwell. The dwell varies according to the time available and the engine requirements.

2) Yes, to a point. The DRP occurs at the same angle based on the initial timing setting.

3) Yes, higher RPM, less time for dwell. There is typically a minimum allowed firing time of 600usec's.

4) Dwell in HEI is not fixed.

9) Dwell is not controlled by the module. The peak current is controlled. This is not the same as dwell.

10) See #9. There is RPM compensation for timing when in bypass mode.

RBob.

#10

Supreme Member

Join Date: Feb 2000

Location: Johnstown, Ohio

Posts: 1,416

Likes: 0

Received 0 Likes

on

0 Posts

Car: 84 Z28

Engine: 355 (fastburn heads, LT4 HOT cam)

Transmission: 700R4

Axle/Gears: 9-bolt, 3.27

Broken Record

Sorry to sound like a broken record here, but I *think* I have the killer setup. Similar to what is used on the LT5 ZR1's, and marine engines, but using more readily available stuff, namely the Cadillac Northstar parts.

http://www.jpteck.com/efi/northstar

I'm STILL looking to get some dimensions from a northstar Crank for my replacement trigger wheel in order to test some of this out. I have NOT given up on the project, I just haven't found the info I need!

With the N* setup, you wire it up as a stock HEI (to the DIS module, instead of the HEI module, add power and cranks signal the the module) and a couple simple code changes to the chip you run! I think I have it close here, but have a few missing links! Keep watching, I WILL post when I get more info!

http://www.jpteck.com/efi/northstar

I'm STILL looking to get some dimensions from a northstar Crank for my replacement trigger wheel in order to test some of this out. I have NOT given up on the project, I just haven't found the info I need!

With the N* setup, you wire it up as a stock HEI (to the DIS module, instead of the HEI module, add power and cranks signal the the module) and a couple simple code changes to the chip you run! I think I have it close here, but have a few missing links! Keep watching, I WILL post when I get more info!

#11

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

The dwell varies according to the time available and the engine requirements.

If an 'electronic' distributor is used to feed the EST signal to four ignition modules in a waste spark system, then the dwell compensation will be way off because each module only sees a fourth of the engine RPM.

The DRP occurs at the same angle based on the initial timing setting.

Dwell is not controlled by the module. The peak current is controlled. This is not the same as dwell.

The primary coil current should be proportional to spark intensity.

There is RPM compensation for timing when in bypass mode.

#12

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Originally posted by JoBy

Then how does the ECM compensate for dwell time when calculating the EST signal?

If an 'electronic' distributor is used to feed the EST signal to four ignition modules in a waste spark system, then the dwell compensation will be way off because each module only sees a fourth of the engine RPM.

Ok

Does the module limit the current in the coil and 'wait' for a spark timing signal?

The primary coil current should be proportional to spark intensity.

When useing a timing light I saw that the 6 degree initial timing jumped to 12 degrees at a higher RPM when in bypass mode.

Then how does the ECM compensate for dwell time when calculating the EST signal?

If an 'electronic' distributor is used to feed the EST signal to four ignition modules in a waste spark system, then the dwell compensation will be way off because each module only sees a fourth of the engine RPM.

Ok

Does the module limit the current in the coil and 'wait' for a spark timing signal?

The primary coil current should be proportional to spark intensity.

When useing a timing light I saw that the 6 degree initial timing jumped to 12 degrees at a higher RPM when in bypass mode.

Can also check one of the code hacs. Most of the C3/P4 stuff I've seen use the same routines.

Basically, the maximum dwell is the amount of time required to charge the coil. It is then reduced according to the actual amount of time available. The '148 code which uses DIS (some/all apps?) is the same as the code in $8D which is a distributor.

Not knowing how the internals of a DIS module operate, I can't say whether it is possible to dwell those coils longer then one can with a distributor setup.

I do know that folks have put DIS on distributor apps, along with stuff like CDI's on DIS, and CnP in place of both DIS and distributor.

The ignition module will limit the peak current while waiting for a fire signal.

RBob.

#13

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

So any 'non stock' ignition running from the EST signal could be way off at higher RPM compared to the desired spark timing in the ECM.

Even if you run the expensive FAST eDist from the stock ECM your actual timing might be way off the calibration because of compensation routines in the ECM, like voltage compenation or RPM compenation.

A modified ECM code with all 'compensation' removed and a EDIS8 would give you much better control over spark timing, and more spark power at higher RPM.

Even if you run the expensive FAST eDist from the stock ECM your actual timing might be way off the calibration because of compensation routines in the ECM, like voltage compenation or RPM compenation.

A modified ECM code with all 'compensation' removed and a EDIS8 would give you much better control over spark timing, and more spark power at higher RPM.

#14

TGO Supporter

Join Date: Aug 2001

Location: NJ/PA

Posts: 1,008

Likes: 0

Received 0 Likes

on

0 Posts

Car: Yes

Engine: Many

Transmission: Quite a few

JP84Z430HP,

I have a drawing of a trigger wheel, its only based on a guesstimate using the northstar documents running around on the board here. I've drawn a 6" wheel, and since the module needs the signals measured in degrees, as long as you have the notches in the right place, then it should be ok... I used that timing diagram to figure out the approximate gap spacing for the notches, and the other diagram gives you the pattern and position of the notches. you could make the wheel 2ft in diamater if you wanted to.....of course, nothing is tested yet, cause I have to get the wheel machined.

I also planned to just use the northstar ignition module, and look at the outputs on a scope to match em up to a regular hei module. There have been grumblings that the drp signal needs to be inverted or something, but i haven't verified. the module puts out extra signals, and also wants to see a cam sensor, but it shoudl still work with just the two crank sensors, and just using the right signals, if you don't need sequential control.

if you want the drawing, just PM me or whatever....

sorry to break the dwell conversation, just thought I'm mention the northstar details.

I have a drawing of a trigger wheel, its only based on a guesstimate using the northstar documents running around on the board here. I've drawn a 6" wheel, and since the module needs the signals measured in degrees, as long as you have the notches in the right place, then it should be ok... I used that timing diagram to figure out the approximate gap spacing for the notches, and the other diagram gives you the pattern and position of the notches. you could make the wheel 2ft in diamater if you wanted to.....of course, nothing is tested yet, cause I have to get the wheel machined.

I also planned to just use the northstar ignition module, and look at the outputs on a scope to match em up to a regular hei module. There have been grumblings that the drp signal needs to be inverted or something, but i haven't verified. the module puts out extra signals, and also wants to see a cam sensor, but it shoudl still work with just the two crank sensors, and just using the right signals, if you don't need sequential control.

if you want the drawing, just PM me or whatever....

sorry to break the dwell conversation, just thought I'm mention the northstar details.

#15

Member

Join Date: Jan 2003

Location: Lee County, AL

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 Z28

Engine: 383 Single Plane EFI-NOW RUNNING!

Transmission: T56

Axle/Gears: Not there yet...

Why not get a used Northstar crank, likeTHIS then cut the wheel out of it, get it machined nice and flat and just use that? You would need to know where the wheel is at #1 TDC but that shouldn't be too hard to figure out if you have the actual crank. You would also need to know how to position the sensors, but that info is out there already. This is what I was considering when I was thinking of using the Northstar DIS. Just a thought..................

#16

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Originally posted by JoBy

So any 'non stock' ignition running from the EST signal could be way off at higher RPM compared to the desired spark timing in the ECM.

Even if you run the expensive FAST eDist from the stock ECM your actual timing might be way off the calibration because of compensation routines in the ECM, like voltage compenation or RPM compenation.

A modified ECM code with all 'compensation' removed and a EDIS8 would give you much better control over spark timing, and more spark power at higher RPM.

So any 'non stock' ignition running from the EST signal could be way off at higher RPM compared to the desired spark timing in the ECM.

Even if you run the expensive FAST eDist from the stock ECM your actual timing might be way off the calibration because of compensation routines in the ECM, like voltage compenation or RPM compenation.

A modified ECM code with all 'compensation' removed and a EDIS8 would give you much better control over spark timing, and more spark power at higher RPM.

The eDist will work as planned with a GM ECM.

RBob.

#17

Supreme Member

Join Date: Feb 2000

Location: Johnstown, Ohio

Posts: 1,416

Likes: 0

Received 0 Likes

on

0 Posts

Car: 84 Z28

Engine: 355 (fastburn heads, LT4 HOT cam)

Transmission: 700R4

Axle/Gears: 9-bolt, 3.27

I'd have to look back through my notes (or maybe even my old post on this topic) to see, but I think I had the Crank sensor angle taken care of. It's been a while since looking at the operational details.

The reason I only want the dimensions from a N* crank is so that I can make the wheel any diameter I choose. I plan to mount it in between the balancer and front pulley (See drawings on my page linked above) Once I know for sure the diameter the stock wheel and width (Degrees of rotation) for the notches, I'll be home free! If I were closer to needing it, I would purchase a used crank to measure myself, but since I'm still a little while out, I'll see if anyone can help me out! I have the wheel drawn, with the notches in the proper locations, but I'm just not sure on the notch width. The other thing I still need to get finished is the bracket to mount the sensors, although it should really be pretty easy.

The reason I only want the dimensions from a N* crank is so that I can make the wheel any diameter I choose. I plan to mount it in between the balancer and front pulley (See drawings on my page linked above) Once I know for sure the diameter the stock wheel and width (Degrees of rotation) for the notches, I'll be home free! If I were closer to needing it, I would purchase a used crank to measure myself, but since I'm still a little while out, I'll see if anyone can help me out! I have the wheel drawn, with the notches in the proper locations, but I'm just not sure on the notch width. The other thing I still need to get finished is the bracket to mount the sensors, although it should really be pretty easy.

#18

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

Originally posted by RBob

Rising edge signals start of dwell (coil starts to charge). Falling edge signals fire time.

Rising edge signals start of dwell (coil starts to charge). Falling edge signals fire time.

Using an 'electronic' distributor to feed the EST signal to four HEI modules would not increase spark intensity much because the coil would not use the extra charge time availabe.

What about the DRP signal? Does the ECM use the rising or falling edge?

#19

Supreme Member

Join Date: Jun 2000

Location: In reality

Posts: 7,554

Likes: 0

Received 1 Like

on

1 Post

Car: An Ol Buick

Engine: Vsick

Transmission: Janis Tranny Yank Converter

Originally posted by JoBy

Using an 'electronic' distributor to feed the EST signal to four HEI modules would not increase spark intensity much because the coil would not use the extra charge time availabe.

Using an 'electronic' distributor to feed the EST signal to four HEI modules would not increase spark intensity much because the coil would not use the extra charge time availabe.

4 coils, is better then one, and 8 coils better then 4, for just that reason.

Not to mention that at over 6K RPM, your basically out of time to charge the primary side of a single coil ignition system with a 12v primary. At high RPM, the ~350v primary, drops the coil *Rise Time*, enough to really matter.

Then there is the matter of, the spark just really cascades a reaction in progress, so some engines need ALOT less spark then others due to their inheritant design.

So far, my best setup has been running a DIS, and then an ACCEL 300 CD on each coil. So that even at max RPM, the plug still sees 3x sparks per event.

BTW, there are dual sensor GM v8 HEI distributors out there.

#20

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

Originally posted by Grumpy

Your ignoring the heat generated in the coil. As the primary resistance goes up from heat, the ability to charge the coil drops. Also, to some degree effects the secondary side.

4 coils, is better then one, and 8 coils better then 4, for just that reason.

Not to mention that at over 6K RPM, your basically out of time to charge the primary side of a single coil ignition system with a 12v primary. At high RPM, the ~350v primary, drops the coil *Rise Time*, enough to really matter.

Then there is the matter of, the spark just really cascades a reaction in progress, so some engines need ALOT less spark then others due to their inheritant design.

So far, my best setup has been running a DIS, and then an ACCEL 300 CD on each coil. So that even at max RPM, the plug still sees 3x sparks per event.

BTW, there are dual sensor GM v8 HEI distributors out there.

Your ignoring the heat generated in the coil. As the primary resistance goes up from heat, the ability to charge the coil drops. Also, to some degree effects the secondary side.

4 coils, is better then one, and 8 coils better then 4, for just that reason.

Not to mention that at over 6K RPM, your basically out of time to charge the primary side of a single coil ignition system with a 12v primary. At high RPM, the ~350v primary, drops the coil *Rise Time*, enough to really matter.

Then there is the matter of, the spark just really cascades a reaction in progress, so some engines need ALOT less spark then others due to their inheritant design.

So far, my best setup has been running a DIS, and then an ACCEL 300 CD on each coil. So that even at max RPM, the plug still sees 3x sparks per event.

BTW, there are dual sensor GM v8 HEI distributors out there.

A cooler coil helps, but you are not using the full potential of the ignition coils at high PRM.

By using a 'smart' box like the FAST eDist or something similar a longer dwell time can be used at higher PRM to get the full power from the coil.

With a GEM-ECM to Ford EDIS8 adapter you would get the same thing.

#21

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Originally posted by JoBy

. . .By using a 'smart' box like the FAST eDist or something similar a longer dwell time can be used at higher PRM to get the full power from the coil. . .

. . .By using a 'smart' box like the FAST eDist or something similar a longer dwell time can be used at higher PRM to get the full power from the coil. . .

RBob.

#22

Senior Member

Thread Starter

Join Date: Oct 2001

Location: Timrċ, Sweden

Posts: 930

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Corvette

Engine: Turbo 350

Transmission: 4L80E with TCI T-Com

Originally posted by RBob

I don't believe the eDist will do that, it just sequences the coils by passing the EST signal to the proper coil.

RBob.

I don't believe the eDist will do that, it just sequences the coils by passing the EST signal to the proper coil.

RBob.

#23

Member

Join Date: Jan 2003

Location: Lee County, AL

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 Z28

Engine: 383 Single Plane EFI-NOW RUNNING!

Transmission: T56

Axle/Gears: Not there yet...

Well, the Edist that I have will fire a plain (non smart) coil directly, so it must have some way of handling dwell. It is very adaptable and can be used with either standard or "smart" coils by connecting the coil wires to different outputs on the box. I'll look at the instructions again and see what they say about dwell.

Edit:

I have looked at the edist instructions and here is some text, in part:

"When the selected edge of the cam reference signal is detected, and 2 dwell periods are subsequently detected, output "A" will follow the dwell signal of the next (3rd) dwell period."

So from that I infer that they are relying on the ECM to figure dwell time and the Edist just follows the EST pulse.

Edit:

I have looked at the edist instructions and here is some text, in part:

"When the selected edge of the cam reference signal is detected, and 2 dwell periods are subsequently detected, output "A" will follow the dwell signal of the next (3rd) dwell period."

So from that I infer that they are relying on the ECM to figure dwell time and the Edist just follows the EST pulse.

Last edited by LnealZ28; 10-28-2004 at 12:52 PM.

#24

Moderator

iTrader: (1)

Join Date: Mar 2002

Location: Chasing Electrons

Posts: 18,408

Likes: 0

Received 217 Likes

on

203 Posts

Car: check

Engine: check

Transmission: check

Originally posted by LnealZ28

Well, the Edist that I have will fire a plain (non smart) coil directly, so it must have some way of handling dwell. It is very adaptable and can be used with either standard or "smart" coils by connecting the coil wires to different outputs on the box. I'll look at the instructions again and see what they say about dwell.

Well, the Edist that I have will fire a plain (non smart) coil directly, so it must have some way of handling dwell. It is very adaptable and can be used with either standard or "smart" coils by connecting the coil wires to different outputs on the box. I'll look at the instructions again and see what they say about dwell.

I'd be interested in knowing if the eDist does some sort of dwell control. Either by extending or limiting dwell time.

RBob.

#25

Member

Join Date: Jan 2003

Location: Lee County, AL

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 Z28

Engine: 383 Single Plane EFI-NOW RUNNING!

Transmission: T56

Axle/Gears: Not there yet...

Originally posted by RBob

Point distributors never controlled dwell during key on engine off. If the points happen to be closed the coil is held in a charged state. With engine running the dwell was always 30 degrees (on V8). No matter the RPM. Does the eDist install guide recommend ballast resistors when regular coils are in use?

I'd be interested in knowing if the eDist does some sort of dwell control. Either by extending or limiting dwell time.

RBob.

Point distributors never controlled dwell during key on engine off. If the points happen to be closed the coil is held in a charged state. With engine running the dwell was always 30 degrees (on V8). No matter the RPM. Does the eDist install guide recommend ballast resistors when regular coils are in use?

I'd be interested in knowing if the eDist does some sort of dwell control. Either by extending or limiting dwell time.

RBob.

Thread

Thread Starter

Forum

Replies

Last Post

gixxer92

Engine/Drivetrain/Suspension Parts for Sale

9

05-18-2017 11:20 AM

skinny z

Engine/Drivetrain/Suspension Parts for Sale

5

10-05-2015 06:23 PM

Damon

Tech / General Engine

8

09-26-2015 04:29 PM