low oil pressure after rebuild

#1

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

low oil pressure after rebuild

this is in my wife's s10 blazer. 355, melling high volume oil pump. oem style remote filter and oil cooler in the radiator. oil pressure is around 40 when idling cold. after it gets hot, its near 0, about 20 when driving. sending unit is new, gauge is accurate and confirmed with mechanical gauge. is it possible to modify the pressure relief to raise the pressure, or do i need to get a whole new oil pump meant for high volume and pressure

#2

Supreme Member

Re: low oil pressure after rebuild

Did you weld on the pickup?

#3

Member

Join Date: Mar 2012

Location: Iowa

Posts: 323

Likes: 0

Received 1 Like

on

1 Post

Car: 14 scion tc/91 camaro rs

Engine: 2.5/ 360 pooch

Transmission: 6spd man/th350

Axle/Gears: na/2.73

Re: low oil pressure after rebuild

If the oil pump pickup tube is too far from bottom of oil pan could cause that too.

#4

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

That sounds kinda beyond just anything to do with an oil pump.

I'd be pulling rod bearings to make sure they're not .010" bigger than I thought I paid for.

I'd be pulling rod bearings to make sure they're not .010" bigger than I thought I paid for.

#5

Member

Join Date: Mar 2012

Location: Iowa

Posts: 323

Likes: 0

Received 1 Like

on

1 Post

Car: 14 scion tc/91 camaro rs

Engine: 2.5/ 360 pooch

Transmission: 6spd man/th350

Axle/Gears: na/2.73

Re: low oil pressure after rebuild

Oh ya i also chatted with a guy couple weeks ago, if your oil pump has anticavitation grooves in the gears, that will cause the low oil psi at warm idle, as my engine is doing the same thing and i know its not bearing related.

#6

Re: low oil pressure after rebuild

As I've understood, the rule of thumb is 10 psi per 1,000 RPM. If the gauge(s) are accurate than definitely don't drive to 3,000 RPM until it's fixed. Was the block hot tanked before reassembly? Could you have gunk plugging up an oil passage? Were all the main bearings and cam bearings oil holes lined up?

#7

Senior Member

Join Date: Jun 2000

Location: Glenbeulah, WI

Posts: 599

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1988 Firbird

Engine: 406

Transmission: T-56

Axle/Gears: 4.10

Re: low oil pressure after rebuild

this is in my wife's s10 blazer. 355, melling high volume oil pump. oem style remote filter and oil cooler in the radiator. oil pressure is around 40 when idling cold. after it gets hot, its near 0, about 20 when driving. sending unit is new, gauge is accurate and confirmed with mechanical gauge. is it possible to modify the pressure relief to raise the pressure, or do i need to get a whole new oil pump meant for high volume and pressure

Trending Topics

#8

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

I put all new bearings in the motor, cleaned it out myself. I found out the oil pump was mislabeled as high volume. I picked up a melling high volume, high pressure pump. should have went that route while the motor was out

#9

Member

Join Date: Oct 2009

Location: Ankeny Iowa

Posts: 374

Likes: 0

Received 1 Like

on

1 Post

Car: 84 Camaro

Engine: 357

Transmission: TH350

Axle/Gears: 4.10's / Strange LSD

Re: low oil pressure after rebuild

Did you check your bearing clearances after the new bearings were installed? You don't need a high pressure pump, really don't even need a high volume pump on a SB Chevy but I use one anyway. Sounds more like a clearance issue to me.

Mark.

Mark.

#10

Re: low oil pressure after rebuild

Was this a complete rebuild? or did you just roll some new bearings in. I would think if it was a rebuild then I'd be thinking about bearing issues or galley plugs leaking or missing.

I would also think that even cold, you should be bumping against that bypass spring and making 60psi...even on a stock pressure pump.

I would also think that even cold, you should be bumping against that bypass spring and making 60psi...even on a stock pressure pump.

#11

Moderator

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,106

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: low oil pressure after rebuild

Good oil pressure when cold but little to no oil pressure when hot is normally a bearing clearance problem.

Bad rod bearings will make noises. Main bearings will not make noise and neither will spun cam bearings.

Since you just did a rebuild, first thing that comes to mind is incorrect bearings. It's possible the crankshaft was previously ground and you may have installed standard bearings which would cause excess clearance.

The engine needs to come out to be fixed but the first thing you may want to do is pull the oil filter and cut it open to look for bearing material. If there's a lot of metal in the filter then there's major damage inside the engine and repairs may be higher than expected. If there's little (break in metal) or no metal then you probably just have the wrong size bearings installed.

Bad rod bearings will make noises. Main bearings will not make noise and neither will spun cam bearings.

Since you just did a rebuild, first thing that comes to mind is incorrect bearings. It's possible the crankshaft was previously ground and you may have installed standard bearings which would cause excess clearance.

The engine needs to come out to be fixed but the first thing you may want to do is pull the oil filter and cut it open to look for bearing material. If there's a lot of metal in the filter then there's major damage inside the engine and repairs may be higher than expected. If there's little (break in metal) or no metal then you probably just have the wrong size bearings installed.

#12

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

i installed the cam bearings myself, crank was not ground at all. its 40 psi at idle cold, can get up to 60 around 3k. theres about 8 feet of hose between the block and filter, another 6 feet of line to and from the cooler. cooler is thermostatically controlled, so once the oil is hot, it opens up. no unusual metal particles in the oil. ill update once the new pump is in

#13

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

I'm guessing then, you were careful to make sure the new cam bearings went in with the oil hole at around 4:30 - 5:00 or thereabouts?

A new oil pump won't accomplish anything. I know, you feel like you "just have to" try it, after all it's cheeeeeep and all that; but, you'll be wasting your time.

Might want to totally do away with the oil cooler and see what happens. I'd do that A LONG TIME before I'd dink with the pump. Shoulda put that info in your post from the start. If the car has TPI on it, it doesn't need an oil cooler (as opposed to the factory oil warmer) anyway. It'll never see enough stress for the oil to even notice. Get rid of it and sell it, the car will go faster from the weight reduction; except of course your wallet might become heavier. Wouldn't THAT be a damn shame.

A new oil pump won't accomplish anything. I know, you feel like you "just have to" try it, after all it's cheeeeeep and all that; but, you'll be wasting your time.

Might want to totally do away with the oil cooler and see what happens. I'd do that A LONG TIME before I'd dink with the pump. Shoulda put that info in your post from the start. If the car has TPI on it, it doesn't need an oil cooler (as opposed to the factory oil warmer) anyway. It'll never see enough stress for the oil to even notice. Get rid of it and sell it, the car will go faster from the weight reduction; except of course your wallet might become heavier. Wouldn't THAT be a damn shame.

#14

Moderator

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,106

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: low oil pressure after rebuild

What size are those lines? Should be at least 1/2" lines.

I think you have far too much line for remote mounted filter and coolers. I run a remote mounted filter just because it's easier to get to the System 1 filter for routine inspection. Filter is mounted behind the front motor plate along the side of the block and an accumulator is mounted in front of the inner fender. I don't think I have more than 6 feet of external lines total.

I've reused pumps after engine failures. Take them apart, clean any bearing material that may be in them and put them back together. It takes a lot of wear and tear to fail a pump. I've failed a lot of engines but none from an oil pump problem. I've snapped a lot of con rods and rod bolts over the years.

I think you have far too much line for remote mounted filter and coolers. I run a remote mounted filter just because it's easier to get to the System 1 filter for routine inspection. Filter is mounted behind the front motor plate along the side of the block and an accumulator is mounted in front of the inner fender. I don't think I have more than 6 feet of external lines total.

I've reused pumps after engine failures. Take them apart, clean any bearing material that may be in them and put them back together. It takes a lot of wear and tear to fail a pump. I've failed a lot of engines but none from an oil pump problem. I've snapped a lot of con rods and rod bolts over the years.

#15

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

turns out the pump is a rebadged sealed power. if you read my original post, its in an s10 blazer, so a remote filter is required to clear the front driveshaft and pumpkin. oil hose is 1/2" and its the factory style cooler in the radiator. i cant remember for certain, but i put the oil holes at 11 or 1. my engine guy has always put them in that way, and that was their orientation when i pulled them out. its a 98 2 bolt block, the oil galley for the cam bearings surrounds the bearing, so there isnt a way for them to be misaligned. went back through all the receipts and confirmed all bearings were standard sized. still had the boxes and double confirmed all standard. ill be trying the oil pump next week, ill update when its done

Last edited by Casey Meyers; 09-12-2013 at 07:16 PM.

#16

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

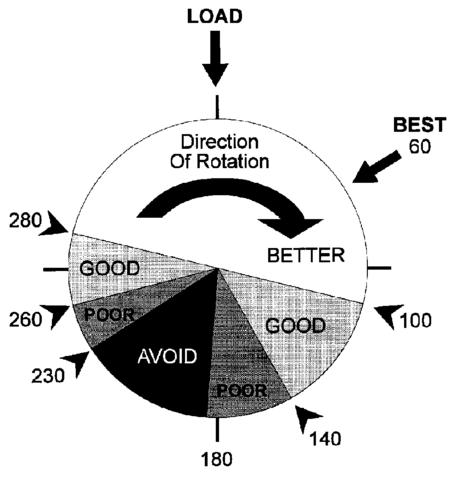

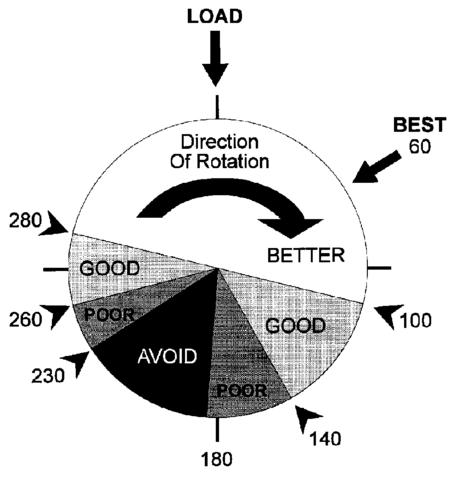

but i put the oil holes at 11 or 1

THIMK... The cam is constantly being pressed downwards by the valve train. Never has even the remotest chance of touching the bearings up at the top. It needs oil at the bottom therefore. Oil should be introduced to the moving thing just before it reaches the point of maximum load. Furthermore, whatever clearance there is in those bearings, is ALL up at the top; meaning, if the holes are up there, they're nothing but a MASSIVE internal oil leak.

Next time you build a motor, put em in in the RIGHT place, and get yourself about 15 free oil psi.

Year of the block doesn't matter. They've been built exactly like that since 1955.

Those grooves behind the cam bearings are actually the passage to the mains and rods... oil goes up from the pump, into a vertical passage that goes all the way to the hole behind the dist, except that there's a drive plug about an inch above the rear main cap parting line, and a horiz passage leading to the oil filter just below that plug, then another horiz passage leading back from the filter (might want to make sure that plug is in there while you're replacing the main & rod bearings that have failed and correctly installing the new cam bearings) above the plug. That passage connects to the rear cam bearing journal and around that groove, and there's 3 holes leading away from it, one above the journal, one to the driver's side, and one to the pass side. There are 3 passages drilled all the way from the front to the rear of the block: the one on the pass side passes through the dist body hole, allowing the bosses and groove around the dist body near the bottom to complete it (might want to take a look at that, make sure there's not another internal oil leak there), and feeds the pass side lifters. One on the left feeds the driver's side lifters. The one above the cam feeds ALL the bearings: in each main bearing saddle there's a hole drilled from the saddle up through the cam bearing journal and into that passage. The 3 front-rear passages have plugs in them at both the front and rear of the block. If you failed to do the basic upgrade of drilling and tapping the 3 holes behind the cam sprocket, then while you're putting in new main & rod bearings and correctly installing new cam bearings, it might be a good time to do this; if those plugs fall out, that's another way you can end up with a MASSIVE internal oil leak. I'd recommend drilling the 2 on the sides with about a #70 drill bit to oil the timing chain.

While you're doing all that, you can probably just put the same pump back on, 99.999999% odds there's not a thing in the world wrong with it. I know, everybody's JUST GOTTA think that when their oil pressure goes away, they JUST GOTTA try a pump; but it's futile. They basically don't go bad except by breaking completely and completely stopping working. They don't do what you JUST GOTTA think yours is doing. But that's not how they fail. That's not what's wrong.

Re-think all that oil line plumbing while you're at it; it's not doing you any favors either. Put in the ABSOLUTE LEAST POSSIBLE amount of it you can, and NOTHING BUT a filter. No cooler.

Last edited by sofakingdom; 09-14-2013 at 03:24 PM.

#17

Re: low oil pressure after rebuild

Those grooves behind the cam bearings are actually the passage to the mains and rods... oil goes up from the pump, into a vertical passage that goes all the way to the hole behind the dist, except that there's a drive plug about an inch above the rear main cap parting line, and a horiz passage leading to the oil filter just below that plug, then another horiz passage leading back from the filter (might want to make sure that plug is in there while you're replacing the main & rod bearings that have failed and correctly installing the new cam bearings). That passage connects to the rear cam bearing journal and around that groove, and there's 3 holes leading away from it, one above the journal, one to the driver's side, and one to the pass side. There are 3 passages drilled all the way from the front to the rear of the block: the one on the pass side passes through the dist body hole, allowing the bosses and groove around the dist body near the bottom to complete it (might want to take a look at that, make sure there's not another internal oil leak there), and feeds the pass side lifters. One on the left feeds the driver's side lifters. The one above the cam feeds ALL the bearings: in each main bearing saddle there's a hole drilled from the saddle up through the cam bearing journal and into that passage. The 3 front-rear passages have plugs in them at both the front and rear of the block. If you failed to do the basic upgrade of drilling and tapping the 3 holes behind the cam sprocket, then while you're putting in new main & rod bearings and correctly installing new cam bearings, it might be a good time to do this; if those plugs fall out, that's another way you can end up with a MASSIVE internal oil leak. I'd recommend drilling the 2 on the sides with about a #70 drill bit to oil the timing chain.

#18

Supreme Member

iTrader: (1)

Join Date: Aug 2007

Location: Bright, IN

Posts: 1,390

Likes: 0

Received 0 Likes

on

0 Posts

Car: '86 Bird, 96 ImpalaSS, 98 C1500XCab

Engine: LG4, LT1, L31

Transmission: 700R4, 4L60E, 4L60E

Axle/Gears: 3.73 Tors, 4.88 spool, 3.73 Eaton

Re: low oil pressure after rebuild

Ive read many books, watched many videos, learned a lot over the years (a lot from you!), and NEVER have I had that oil system explained that well. Most of the stuff I've read just glosses over it. I guess it's a "can't do anything about it, dont worry about it, just put the plugs in the places on the diagram and go about your business" kind of thing...

You've outdone yourself this time, Sofa!

THAT is one of the most valuable posts I've seen on any automotive forum.

#19

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

Thanks guys. Always glad to be informative.

I've often wondered why that system isn't explained in detail anywhere... early in my "career" of doing this, I just studied a block until I figured out where everything went. Not the easiest thing in the world, to try to see it from all different angles.

On a related note, another thing that can go wrong with that system, uncomfortably common in the 70s blocks, is that the front-to-rear passages are drilled halfway from each end and are supposed to meet in the middle; but they DON'T always. I recall one block I was building; during teardown, my habit was to remove the screw-in plugs in the back, and stick a 3/8" rod down the passage to knock out the front ones; but it wouldn't go. In fact a ¼" rod wouldn't even go through, the passage was so far misaligned. Wouldn't surprise me if the very reason for that block being a core right then instead of a running motor, was for spinning front rod and/or main bearings from running dry, even while the gauge at the rear port was reading good oil pressure. A lot of blocks have a 1/8" plug off to the side of that passage up at the front, above the timing cover; a gauge there would probably have read VERY differently from one in the rear.

Here's a few pics I found; none is really very good or complete, but with the 3, you can see most of what's going on. The one shows the plug in the vertical passage and the 2 horiz passages to the oil filter; another shows how the passage goes around behind the cam bearing; and the one of the whole engine shows the whole thing except with LOTS of critically important details completely left out.

Note how many passages there are, that go at odd angles. Keep in mind that they have to be drilled SOMEHOW; so some of those odd plugs you see in strange places, are related to that. For example, the reason for the 1/8" plug that's half under the edge of the driver's side head at the rear, shows up in the middle pic. And the place where there's an OPSU right above the filter in some applications, is left over from drilling the upper horiz passage. And so on.

I've often wondered why that system isn't explained in detail anywhere... early in my "career" of doing this, I just studied a block until I figured out where everything went. Not the easiest thing in the world, to try to see it from all different angles.

On a related note, another thing that can go wrong with that system, uncomfortably common in the 70s blocks, is that the front-to-rear passages are drilled halfway from each end and are supposed to meet in the middle; but they DON'T always. I recall one block I was building; during teardown, my habit was to remove the screw-in plugs in the back, and stick a 3/8" rod down the passage to knock out the front ones; but it wouldn't go. In fact a ¼" rod wouldn't even go through, the passage was so far misaligned. Wouldn't surprise me if the very reason for that block being a core right then instead of a running motor, was for spinning front rod and/or main bearings from running dry, even while the gauge at the rear port was reading good oil pressure. A lot of blocks have a 1/8" plug off to the side of that passage up at the front, above the timing cover; a gauge there would probably have read VERY differently from one in the rear.

Here's a few pics I found; none is really very good or complete, but with the 3, you can see most of what's going on. The one shows the plug in the vertical passage and the 2 horiz passages to the oil filter; another shows how the passage goes around behind the cam bearing; and the one of the whole engine shows the whole thing except with LOTS of critically important details completely left out.

Note how many passages there are, that go at odd angles. Keep in mind that they have to be drilled SOMEHOW; so some of those odd plugs you see in strange places, are related to that. For example, the reason for the 1/8" plug that's half under the edge of the driver's side head at the rear, shows up in the middle pic. And the place where there's an OPSU right above the filter in some applications, is left over from drilling the upper horiz passage. And so on.

Last edited by sofakingdom; 09-13-2013 at 05:43 PM.

#21

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

i know of all the oil passages, we covered that while in school when we blueprinted 350 blocks. if 11 or 1 is such a terrible position for the oil holes in the cam bearing, why were they like that from the factory? the engine had never been opened up previous to me. when the block was bored out, the machinist pulled all the plugs and cleaned the galleys before installing plugs. all the plugs for the oil galleys at the front and rear were already threaded in, not pressed in. i will pull the front main and rod bearings and inspect them, and pull the rear to check that the galley plug is in. i know how everyone thinks the pump is the issue, i was taught the same thing 6 years ago, that the pump is 99% of the time not the issue. but given the oil pressure does not drop until the cooler opens, and there is no coolant in the oil or oil in the coolant, that suggests the brand new radiator is not bad. the oil cooler is needed for towing, and knowing how my wife drives, it needs all the cooling possible.

rod bearings are 2555cp and main are 4663m. everything was tight when assembled, no slop. the engine is very quiet, no noise from the top or bottom. the engine in my car and my truck are both noisier and neither of those were built by me. i would think that if the crank was undersized (which it is not, i did mike them), it wouldn't have any oil pressure regardless of temp. when i was priming the engine, the drill did seem to have a hard time. when i would let off, it would spin back. oil was coming from each rocker arm

rod bearings are 2555cp and main are 4663m. everything was tight when assembled, no slop. the engine is very quiet, no noise from the top or bottom. the engine in my car and my truck are both noisier and neither of those were built by me. i would think that if the crank was undersized (which it is not, i did mike them), it wouldn't have any oil pressure regardless of temp. when i was priming the engine, the drill did seem to have a hard time. when i would let off, it would spin back. oil was coming from each rocker arm

Last edited by Casey Meyers; 09-18-2013 at 06:30 PM.

#22

Member

Join Date: Mar 2012

Location: Iowa

Posts: 323

Likes: 0

Received 1 Like

on

1 Post

Car: 14 scion tc/91 camaro rs

Engine: 2.5/ 360 pooch

Transmission: 6spd man/th350

Axle/Gears: na/2.73

Re: low oil pressure after rebuild

I dont know if this was covered already but.... if youre oil pressure actually drops off when oil t-stat opens then id say lack of oil in oil pan.

#23

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

it's a 7 quart pan, but with the pump having a 3/4" opening, i could not use the sump included with the pan. i used a stock style one, press fit, and the top of the screen is about an inch higher than the included sump. its possible, and is a reason why i want to change the pump

#25

Moderator

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,106

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: low oil pressure after rebuild

Should be roughly 1/8" - 3/8" off the bottom of the pan.

#26

Senior Member

Join Date: May 2002

Location: loxahatchee fla

Posts: 564

Likes: 0

Received 0 Likes

on

0 Posts

#27

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

anyone have a picture of the cap that is supposed to be under the rear main cap? i can't find any pictures to compare to. i have the bottom end apart, the mains had a few scuffs in them from dirt or something entering at some point. nothing wiped out, no babbit was gone, but im going to roll in a new set of bearings anyway. rods looked good. only bits in the oil pan were very fine steel from the rings, no shavings or slivers. according to the haynes manual and a few other sources, there is not supposed to be a gasket for the oil pump mounting. would it hurt to make one and put it on there?

#28

Re: low oil pressure after rebuild

anyone have a picture of the cap that is supposed to be under the rear main cap? i can't find any pictures to compare to. i have the bottom end apart, the mains had a few scuffs in them from dirt or something entering at some point. nothing wiped out, no babbit was gone, but im going to roll in a new set of bearings anyway. rods looked good. only bits in the oil pan were very fine steel from the rings, no shavings or slivers. according to the haynes manual and a few other sources, there is not supposed to be a gasket for the oil pump mounting. would it hurt to make one and put it on there?

The oil pump does not use a gasket so don't put one in there.Keep it as simple as it is.

#30

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

You don't need a "picture" of the "cap" that goes in there; all it is, is a ½" dia plug just like a freeze plug, as shown in the drawing I posted earlier.

Look in the hole. Either there's a plug there, or there's not.

THIMK about "dirt or something entering" the main bearings. THINK. Where would this alleged "something" have come from? How many places can you think of that it possibly could have been in RIGHT BEFORE it miraculously appeared in the bearings? Once you get a handle on THAT, it will become IMMEDIATELY OBVIOUS why you need to tear the motor down, remove the cam bearings and ALL the oil passage plugs YOURSELF FIRST (or stand there and watch them do it BEFORE it's vatted), get it dunked, come back and pick it up, take it to the quarter car wash and run a rifle brush through all the oil passages and a toothbrush-sized wire brush all in those groove passages behind the cam bearings, take it back and get it dunked again, and THEN put the cam bearings in as I described, which is the location that is well and widely known to work the best, for the reasons I clearly described. DO NOT do it like that drawing you posted, unless you just really enjoy doing this over and over to an expensive garage ornament, instead of driving your car.

Once you get a handle on THAT, it will become IMMEDIATELY OBVIOUS why you need to tear the motor down, remove the cam bearings and ALL the oil passage plugs YOURSELF FIRST (or stand there and watch them do it BEFORE it's vatted), get it dunked, come back and pick it up, take it to the quarter car wash and run a rifle brush through all the oil passages and a toothbrush-sized wire brush all in those groove passages behind the cam bearings, take it back and get it dunked again, and THEN put the cam bearings in as I described, which is the location that is well and widely known to work the best, for the reasons I clearly described. DO NOT do it like that drawing you posted, unless you just really enjoy doing this over and over to an expensive garage ornament, instead of driving your car.

Look in the hole. Either there's a plug there, or there's not.

THIMK about "dirt or something entering" the main bearings. THINK. Where would this alleged "something" have come from? How many places can you think of that it possibly could have been in RIGHT BEFORE it miraculously appeared in the bearings?

Once you get a handle on THAT, it will become IMMEDIATELY OBVIOUS why you need to tear the motor down, remove the cam bearings and ALL the oil passage plugs YOURSELF FIRST (or stand there and watch them do it BEFORE it's vatted), get it dunked, come back and pick it up, take it to the quarter car wash and run a rifle brush through all the oil passages and a toothbrush-sized wire brush all in those groove passages behind the cam bearings, take it back and get it dunked again, and THEN put the cam bearings in as I described, which is the location that is well and widely known to work the best, for the reasons I clearly described. DO NOT do it like that drawing you posted, unless you just really enjoy doing this over and over to an expensive garage ornament, instead of driving your car.

Once you get a handle on THAT, it will become IMMEDIATELY OBVIOUS why you need to tear the motor down, remove the cam bearings and ALL the oil passage plugs YOURSELF FIRST (or stand there and watch them do it BEFORE it's vatted), get it dunked, come back and pick it up, take it to the quarter car wash and run a rifle brush through all the oil passages and a toothbrush-sized wire brush all in those groove passages behind the cam bearings, take it back and get it dunked again, and THEN put the cam bearings in as I described, which is the location that is well and widely known to work the best, for the reasons I clearly described. DO NOT do it like that drawing you posted, unless you just really enjoy doing this over and over to an expensive garage ornament, instead of driving your car.

#31

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

Verified the cap was in place. Likely source of dirt getting in was from it being powerwashed with rags over the tb opening and dizzy opening. Rolled in new crank bearings. Pulled all rods, were all ok. Pulled the front cover and slid the cam forward enough to use a borescope and cam bearings are good. Buttoned it all bacl up, replaced oil filter and primed it. Have 70 psi on the gauge with a 3k rpm drill. Taking the pressure at the port next to the dizzy, not above the oil filter. Have to replace a freeze plug before i can run it and check final pressures. Since the plug next to the dizzy is the final point in the oiling system, how different would it be vs the port above the filter?

#32

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,023

Received 1,662 Likes

on

1,261 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: low oil pressure after rebuild

Should be no more than a psi or 2, since the only things between there are the horiz passage with the fat right-pointing arrow in that dwg up there, and the part of the vertical passage above the plug; and both of those are around 3/8" dia.

#33

Senior Member

Join Date: May 2002

Location: loxahatchee fla

Posts: 564

Likes: 0

Received 0 Likes

on

0 Posts

Re: low oil pressure after rebuild

Verified the cap was in place. Likely source of dirt getting in was from it being powerwashed with rags over the tb opening and dizzy opening. Rolled in new crank bearings. Pulled all rods, were all ok. Pulled the front cover and slid the cam forward enough to use a borescope and cam bearings are good. Buttoned it all bacl up, replaced oil filter and primed it. Have 70 psi on the gauge with a 3k rpm drill. Taking the pressure at the port next to the dizzy, not above the oil filter. Have to replace a freeze plug before i can run it and check final pressures. Since the plug next to the dizzy is the final point in the oiling system, how different would it be vs the port above the filter?

I DON,T THINK YOU HAVE THE TRUE CONCEPT OF HYDRAULICS DOWN IN YOUR MIND CORRECTLY.

Pressure is a measure of resistance to flow, if your measuring 70psi at one point in the oil passage the other end should be nearly the same reading, I doubt you can measure the difference with automotive gauges

points A,B,C should be very similar pressures, the only reason they are not IDENTICAL is because the oil system in a small block has about 100 points where oil seeps out under pressure thru bearing clearances etc.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

http://www.grc.nasa.gov/WWW/k-12/Win...principle.html

"Pascal's law states that when there is an increase in pressure at any point in a confined fluid, there is an equal increase at every other point in the container."

Last edited by grumpyvette; 09-23-2013 at 08:48 AM.

#34

Junior Member

Thread Starter

iTrader: (2)

Join Date: Mar 2013

Location: Biglerville, PA

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Car: 86 Z28

Engine: 385 HSR

Transmission: T56 stage 2

Axle/Gears: Moser 9" 3.70 locker

Re: low oil pressure after rebuild

It was a simple question, I did not know for sure if there would be any reason, aside from a restriction, that would cause the pressures to be different. I am well versed in hydraulics, I just don't work on engine or hydraulic systems every single day.

anywho, I let the engine run for a while and get up to full temp. its holding 10 psi at idle, 40-50 around 2500. i am looking for a corvette oil filter adapater to remove the remote filter and oil cooler to see if that changes anything. i used a trans dapt adapter and it didnt look high quality. i think that plus the 90* hose fittings could be slowing things up. if that doesn't help, then the engine is getting yanked out, stripped down and done over again. but for now it seems ok

anywho, I let the engine run for a while and get up to full temp. its holding 10 psi at idle, 40-50 around 2500. i am looking for a corvette oil filter adapater to remove the remote filter and oil cooler to see if that changes anything. i used a trans dapt adapter and it didnt look high quality. i think that plus the 90* hose fittings could be slowing things up. if that doesn't help, then the engine is getting yanked out, stripped down and done over again. but for now it seems ok

#36

Moderator

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,106

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: low oil pressure after rebuild

10 psi per 1000 rpm with hot oil is the bare minimum but if I was idling at 1000 rpm and only had 10 psi, I'd be a little concerned. I wouldn't want to see it lower than 15 psi at an idle with hot oil. 20 would be better.

Thread

Thread Starter

Forum

Replies

Last Post

ambainb

Camaros for Sale

11

04-25-2016 09:21 PM