1989 305 TPI problems with pushrods and rockers after bebuild

#1

1989 305 TPI problems with pushrods and rockers after bebuild

Hello

2 Years ago i rebuilt my 1989 305 TPI SBC.

I used the following components.:

Stock short Block rebored with new pistons and Comp Cam with 0,495 lift, high flow oil pump, stock hydraulic lifters

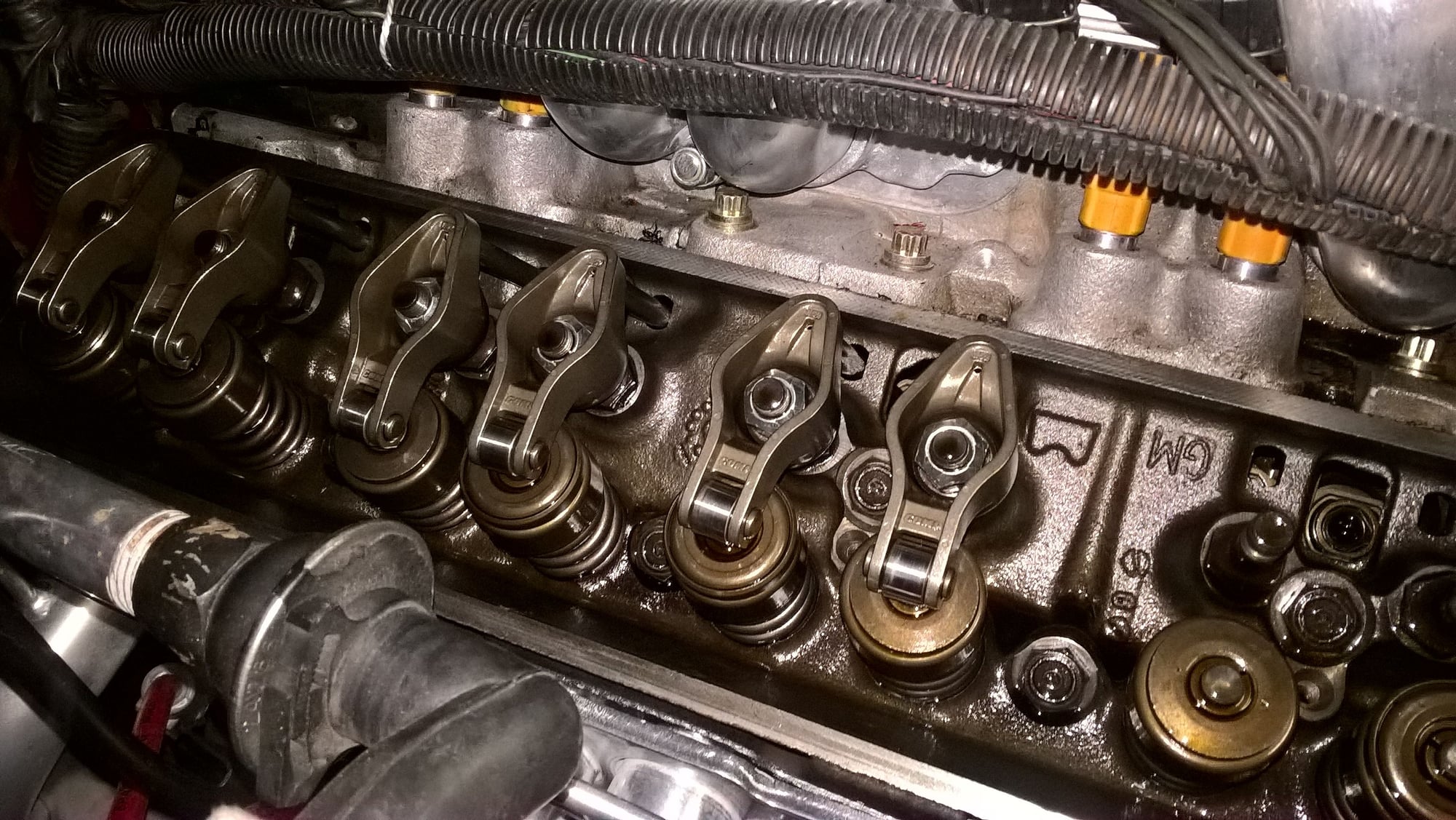

Stock heads (081 ; ported) with new valves, screwed Comp studs, Comp CCA- RP1417-16 Rockers and pushrods

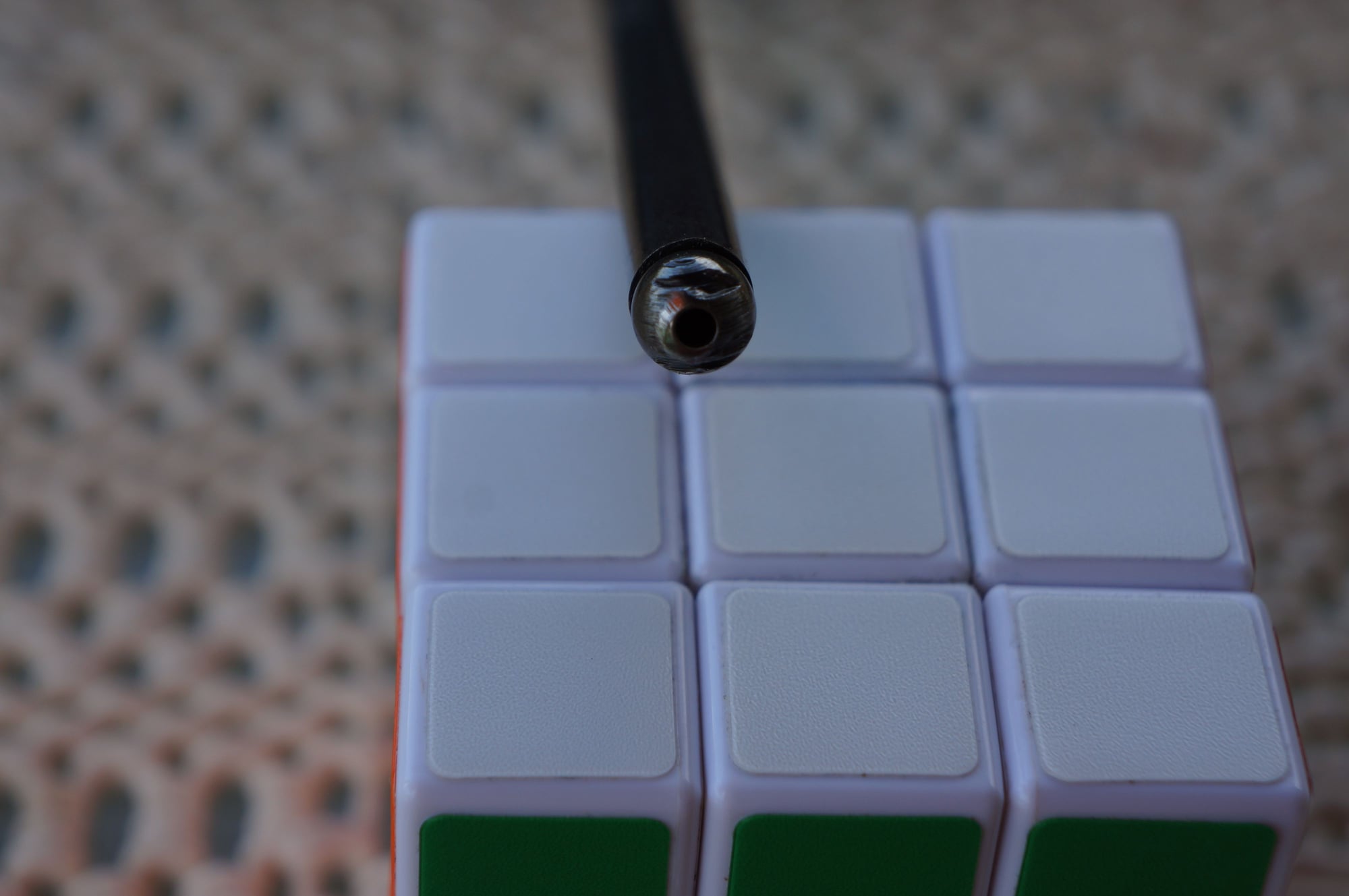

Now the engine has ~ 4000 Miles and i have a problem with the rockers and pushrods. The end that is connected to the lifter ist in perfect condition. The upper end shows a fatal wear pattern. All pushrods are affected (one more, ...). form 2 pushrods the ball end broke off. The contact surface of the rocker arm is also affected.

I make some pictures. Excuse my bad english.

2 Years ago i rebuilt my 1989 305 TPI SBC.

I used the following components.:

Stock short Block rebored with new pistons and Comp Cam with 0,495 lift, high flow oil pump, stock hydraulic lifters

Stock heads (081 ; ported) with new valves, screwed Comp studs, Comp CCA- RP1417-16 Rockers and pushrods

Now the engine has ~ 4000 Miles and i have a problem with the rockers and pushrods. The end that is connected to the lifter ist in perfect condition. The upper end shows a fatal wear pattern. All pushrods are affected (one more, ...). form 2 pushrods the ball end broke off. The contact surface of the rocker arm is also affected.

I make some pictures. Excuse my bad english.

#3

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

As you can see, the base of the rocker has a blue color, i think that points to a cooling problem (no oil ????).

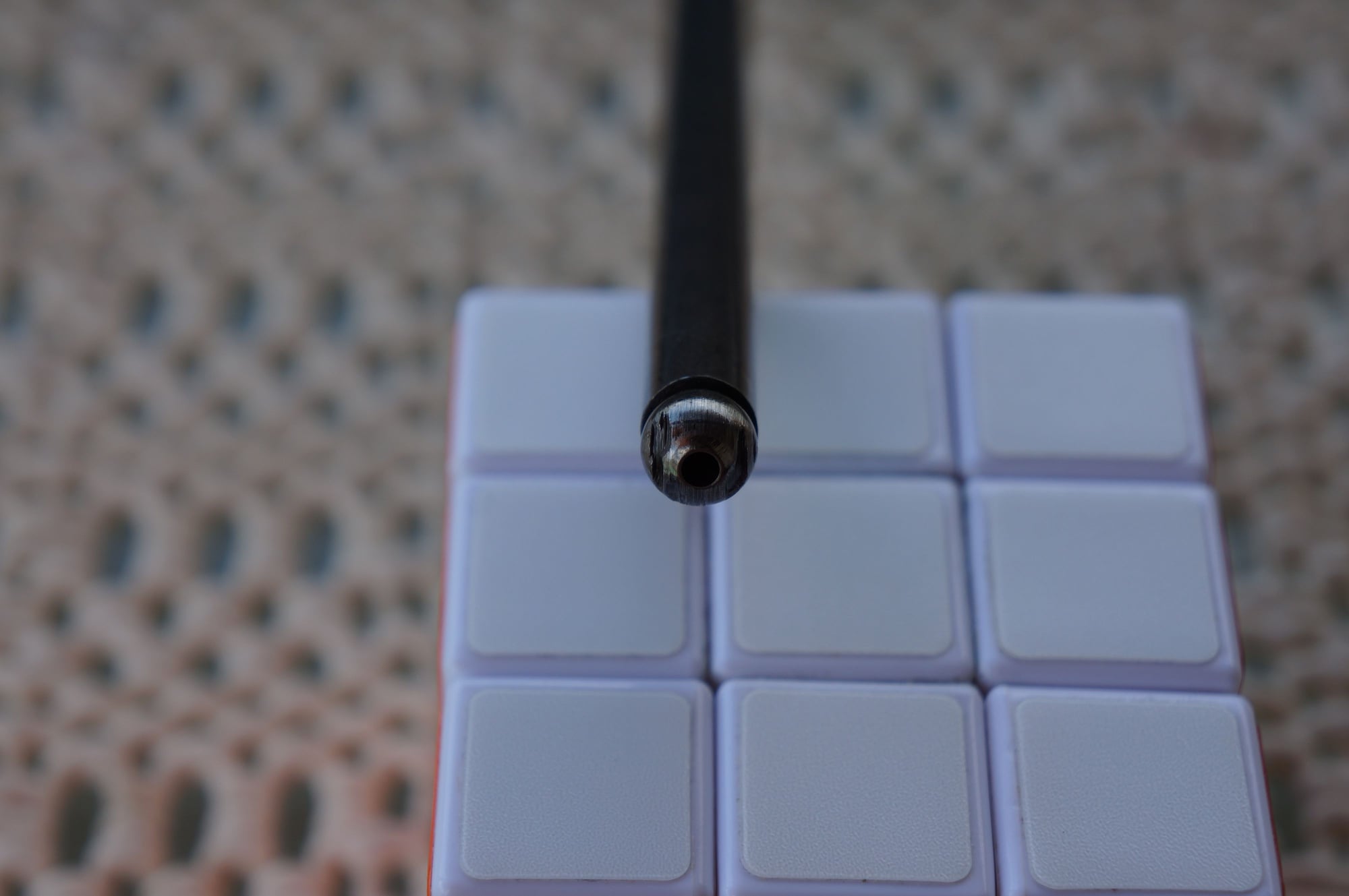

I forgot, the new cam needs stronger springs.

I used that springs "MAN-13091-16" with 370lbs/in

Is it possible to get problems with this combination ?

I used a preoiling tool before the engine starts the first time.

At all rockers flowed oil !

Now i dont know what to do ? Should i use the same parts again ?

I forgot, the new cam needs stronger springs.

I used that springs "MAN-13091-16" with 370lbs/in

Is it possible to get problems with this combination ?

I used a preoiling tool before the engine starts the first time.

At all rockers flowed oil !

Now i dont know what to do ? Should i use the same parts again ?

#4

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Is there any sign of the push rods rubbing on the hole in the head casting that they pass through? Any sign of the rocker studs with the push rods failed, having a witness mark below the point that the rocker ball sat on them?

The failure may have been caused by the push rods you used being too long, and making the rocker try to travel past the end of its slot; or, if the push rods rubbed on the head, the tip of the push rod being forced out of the seat in the rocker at some point during its travel.

The rocker ball area always gets EXTREMELY hot. That's the number one reason for using roller rockers instead of ball rockers: they eliminate that place with lots of friction. That doesn't look too bad... mostly normal actually... sometimes they will get so hot they get covered in ash from burnt oil.

You mention "ball" on the push rod. I'd strongly recommend upgrading from those 3-pc units to 1-pc push rods such as https://www.summitracing.com/parts/c...5-16/overview/, in whatever length is correct to produce the best possible geometry in your motor which can only be determined by measuring. Buy an adjustable push rod such as https://www.summitracing.com/parts/cca-7702-1 and a pair of very light springs to substitute for the valve springs, install them on the intake and exhaust of a cylinder, mark the tips of the valve stems with a Sharpie or similar marker, take out all the spark plugs, turn the engine several revolutions by hand, and find the push rod length that results in the narrowest possible sweep mark produced by the rocker on the valve stems. Then order a set of the above type of push rods (they come in different part numbers with .050" length increments) in that length. You should probably check at least one cylinder on each side of the engine.

The failure may have been caused by the push rods you used being too long, and making the rocker try to travel past the end of its slot; or, if the push rods rubbed on the head, the tip of the push rod being forced out of the seat in the rocker at some point during its travel.

The rocker ball area always gets EXTREMELY hot. That's the number one reason for using roller rockers instead of ball rockers: they eliminate that place with lots of friction. That doesn't look too bad... mostly normal actually... sometimes they will get so hot they get covered in ash from burnt oil.

You mention "ball" on the push rod. I'd strongly recommend upgrading from those 3-pc units to 1-pc push rods such as https://www.summitracing.com/parts/c...5-16/overview/, in whatever length is correct to produce the best possible geometry in your motor which can only be determined by measuring. Buy an adjustable push rod such as https://www.summitracing.com/parts/cca-7702-1 and a pair of very light springs to substitute for the valve springs, install them on the intake and exhaust of a cylinder, mark the tips of the valve stems with a Sharpie or similar marker, take out all the spark plugs, turn the engine several revolutions by hand, and find the push rod length that results in the narrowest possible sweep mark produced by the rocker on the valve stems. Then order a set of the above type of push rods (they come in different part numbers with .050" length increments) in that length. You should probably check at least one cylinder on each side of the engine.

#5

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Is it possible that the 370lbs/in springs and the 0,495 in lift cam creates to much force for that pushrods ? I think they are not hardened, only heat threated.

I think the next step is to take a look at the geometry to find the correct pushrod length. I found the tool https://www.summitracing.com/parts/pro-66789 to do that.

The new cam should have a smaller base cycle than the stock cam because of the higher lift. That would mean the Pushrods from my set are to short !

I think the next step is to take a look at the geometry to find the correct pushrod length. I found the tool https://www.summitracing.com/parts/pro-66789 to do that.

The new cam should have a smaller base cycle than the stock cam because of the higher lift. That would mean the Pushrods from my set are to short !

#6

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Manley 13091 is a keeper, not a valve spring. Tell us what springs you have and we can maybe guess whether they're adequate. Keep in mind also, there's ALOT more to valve springs than just the max cam lift spec; at least as important, is how they were set up during installation. Specifically, their installed height. What height were yours assembled at? It's possible that this could be the cause, or at least a contributing factor, to your parts failure.

Yes you can use that tool for push rod selection; it's not the most precise thing in the world, but it'll probably get you close enough. You still need an adjustable push rod to go with it.

Don't "assume" ANYTHING about your push rod length. It's true that most often, increasing the cam lift requires longer push rods; but if the block or heads have been milled, head gaskets changed, valve seats ground, etc. etc. etc. etc., all of those things affect the optimum length. There's SO MANY variables that affect it, the only way to get it right, is to measure YOUR parts. Not even, somebody else's pile of parts that are "the same" as yours; YOUR parts.

Yes you can use that tool for push rod selection; it's not the most precise thing in the world, but it'll probably get you close enough. You still need an adjustable push rod to go with it.

Don't "assume" ANYTHING about your push rod length. It's true that most often, increasing the cam lift requires longer push rods; but if the block or heads have been milled, head gaskets changed, valve seats ground, etc. etc. etc. etc., all of those things affect the optimum length. There's SO MANY variables that affect it, the only way to get it right, is to measure YOUR parts. Not even, somebody else's pile of parts that are "the same" as yours; YOUR parts.

Trending Topics

#8

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Those springs are supposed to be set up at 1.750". The one intake that's measured, is set up .065" shorter than that... in other words, already compressed .065" more than it's supposed to be. The end result is, instead of the spring seeing a cam that's .488" max, it looks to the spring as though it's .553". It's no surprise that you're having valve train problems.

The coils are probably hitting each other as they vibrate during the valve motion cycle. That basically acts like meta-to-metal pounding on the parts.

Those are good springs; just, they're not installed right.

What you need is a set of .050" offset keepers, to allow the retainers to sit .050" higher and thus take .050" of improper compression off of the springs. https://www.summitracing.com/parts/t...0444/overview/ for example. Then a set of shims https://www.summitracing.com/parts/cca-4753/overview/ to take up any extra slack if any of them end up with installed height above about 1.76". You'll need a spring micrometer to measure them. https://www.summitracing.com/parts/sum-900032/overview/

This should have been done right at the time the heads were built.

Show us a photo of the valve springs on one cylinder as it is now.

The coils are probably hitting each other as they vibrate during the valve motion cycle. That basically acts like meta-to-metal pounding on the parts.

Those are good springs; just, they're not installed right.

What you need is a set of .050" offset keepers, to allow the retainers to sit .050" higher and thus take .050" of improper compression off of the springs. https://www.summitracing.com/parts/t...0444/overview/ for example. Then a set of shims https://www.summitracing.com/parts/cca-4753/overview/ to take up any extra slack if any of them end up with installed height above about 1.76". You'll need a spring micrometer to measure them. https://www.summitracing.com/parts/sum-900032/overview/

This should have been done right at the time the heads were built.

Show us a photo of the valve springs on one cylinder as it is now.

#9

Member

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Pictures tell me too much pressure/friction on the fulcrum pivot ball generated too much heat. Don't see any signs of contact damage on tyhe slot though could be some on the p-rod end. This makes me wonder if the lifter pre-load was anything it needed to be. I have to wonder how you didn't have plenty of lifter noise?

Yes begin with hardened p-rods of correct length -that checker tool should do the job.

I doubt that cam has a reduced base circle. You need to learn how to adjust the lifter pre-load correctly. But before that you need to verify adequate clearance of valve lift plus 0.060" between the bottom of the spring retainer and the top of the valve seal/guide boss.

AFIK to create that much heat on the rocker arm fulcrum the pivot ball must be needing more oil, maybe somewhat even dry or the pre-load is so much/excessive its generating heat and keeping the valve somewhat open. To much pre-load and the lifter internal plunger can't pump oil up the p-rod.

Yes begin with hardened p-rods of correct length -that checker tool should do the job.

Is it possible that the 370lbs/in springs and the 0,495 in lift cam creates to much force for that pushrods ? I think they are not hardened, only heat threated.

I think the next step is to take a look at the geometry to find the correct pushrod length. I found the tool https://www.summitracing.com/parts/pro-66789 to do that.

The new cam should have a smaller base cycle than the stock cam because of the higher lift. That would mean the Pushrods from my set are to short !

I think the next step is to take a look at the geometry to find the correct pushrod length. I found the tool https://www.summitracing.com/parts/pro-66789 to do that.

The new cam should have a smaller base cycle than the stock cam because of the higher lift. That would mean the Pushrods from my set are to short !

AFIK to create that much heat on the rocker arm fulcrum the pivot ball must be needing more oil, maybe somewhat even dry or the pre-load is so much/excessive its generating heat and keeping the valve somewhat open. To much pre-load and the lifter internal plunger can't pump oil up the p-rod.

#10

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

...

Last edited by NoEmissions84TA; 07-08-2017 at 06:50 PM. Reason: double posted

#11

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Okay, some more bad news. Clearly at least some of your pushrods did not rotate, or stopped rotating. That means that the lifter did not rotate or stopped rotating. When a flat tappet lifter stops rotating, the camshaft lobes are quickly machined into circles. And all that metal then gets circulated through the entire engine, doing further damage. If only 1 lobe is damaged, then you need a new camshaft and lifters. BTW, you said stock lifters. You did not re-use your old lifters, did you?

Proper valve spring setup and valvetrain geometry is CRITICAL. Next time, when you get to the point of prelubing the engine, rotate the engine a few times to check for pushrod rotation. I use a paint marker to paint lines along the length of my pushrods. This makes it easy to check for rotation. And as you already know, oil must flow at the top of every pushrod. Flat tappet camshafts require a specific break-in procedure and with ZDDP added to the oil. I think you already know this.

I see that your rockers are the self-guided type. Therefore, you cannot use guide plates and the pushrod slots in the head have to be opened up, if they already aren't.

Your valve springs are a little stiff for a HFT camshaft. If you can manage to set your installed heights closer to 1.800", then the resultant lower spring pressures will be closer to ideal.

Post pictures of everything.

Proper valve spring setup and valvetrain geometry is CRITICAL. Next time, when you get to the point of prelubing the engine, rotate the engine a few times to check for pushrod rotation. I use a paint marker to paint lines along the length of my pushrods. This makes it easy to check for rotation. And as you already know, oil must flow at the top of every pushrod. Flat tappet camshafts require a specific break-in procedure and with ZDDP added to the oil. I think you already know this.

I see that your rockers are the self-guided type. Therefore, you cannot use guide plates and the pushrod slots in the head have to be opened up, if they already aren't.

Your valve springs are a little stiff for a HFT camshaft. If you can manage to set your installed heights closer to 1.800", then the resultant lower spring pressures will be closer to ideal.

Post pictures of everything.

#12

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

081 heads are Vortec, correct? Did you have the guides machined down for increased retainer-to-seal clearance?

One really dumb question, (I don't think you are a complete idiot but I have seen this before, so no offense) but did you install the rocker ***** with the flat side up?

One really dumb question, (I don't think you are a complete idiot but I have seen this before, so no offense) but did you install the rocker ***** with the flat side up?

#13

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

The engine is from 1989 and has hydraulic lifters, so the pushrods are equal on both sides.

I thighted the nut of the Rocker till there was no more movement of the rod, and then half a rotation more (i think thats correct).

I used the stock retainers (rotatator on exhaust), therfore the installes hight sould be stock.

Yes i cut down the guide boss to got proper clearance.

Installed height: At the exhaust side the height ist near perfect, but there is also damage !

I thighted the nut of the Rocker till there was no more movement of the rod, and then half a rotation more (i think thats correct).

I used the stock retainers (rotatator on exhaust), therfore the installes hight sould be stock.

Yes i cut down the guide boss to got proper clearance.

Installed height: At the exhaust side the height ist near perfect, but there is also damage !

Last edited by Zylinder; 07-09-2017 at 12:09 AM.

#17

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

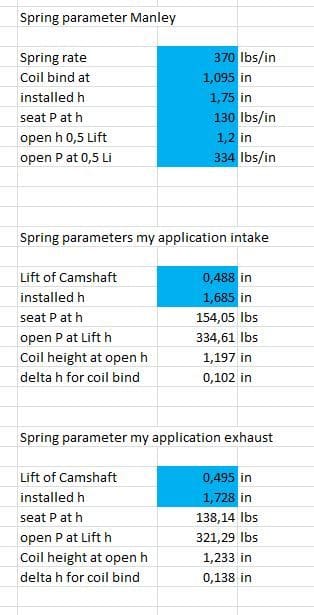

I see a problem already. Your pushrods are guided by the slots in the heads. You CANNOT use self-aligning rockers in your case. You can't guide in 2 places. If you were to re-use your rockers, then those holes would have to be opened up. But since the rockers are now trash (the pushrod cups are damaged - I'm sure), you can now buy the correct rockers.

Without a closer picture, from what I can see, your valvetrain geometry looks acceptable.

Get your spring installed heights set correctly (lose the rotators - use all retainers) and MEASURE for coil bind and retainer-to-seal clearance at full valve lift.

Before you do anything, you should carefully inspect the camshaft and lifters.

Without a closer picture, from what I can see, your valvetrain geometry looks acceptable.

Get your spring installed heights set correctly (lose the rotators - use all retainers) and MEASURE for coil bind and retainer-to-seal clearance at full valve lift.

Before you do anything, you should carefully inspect the camshaft and lifters.

#18

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Your pictures. See what I circled in yellow. You said HYDRAULIC lifter. That sure looks like a ROLLER lifter to me.

What exactly is your camshaft??? Sorry, I have to ask, did you use roller lifters with a flat tappet camshaft?

What exactly is your camshaft??? Sorry, I have to ask, did you use roller lifters with a flat tappet camshaft?

#19

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

These bumps or guide rails is what makes this rocker self-aligning.

#20

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Yes the rockers are self aligning, but i see no problem because the slots in the head are much more restirictive.

But i can use a different type. Which rockers and rods can you recommend ?

Are these Pushrods (from the comp set CCA- RP1417-16) hardened ?

My camshaft is a CCA-08-501-8 with reused stock roller lifters.

I cannot take a look at the lifters and the cam because i dont want to pull the engine ! That is no option.

What do you mean with the yellow circels ? That are inspetion holes (large) and the slots of the rods.

But i can use a different type. Which rockers and rods can you recommend ?

Are these Pushrods (from the comp set CCA- RP1417-16) hardened ?

My camshaft is a CCA-08-501-8 with reused stock roller lifters.

I cannot take a look at the lifters and the cam because i dont want to pull the engine ! That is no option.

What do you mean with the yellow circels ? That are inspetion holes (large) and the slots of the rods.

Last edited by Zylinder; 07-09-2017 at 03:07 AM.

#22

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

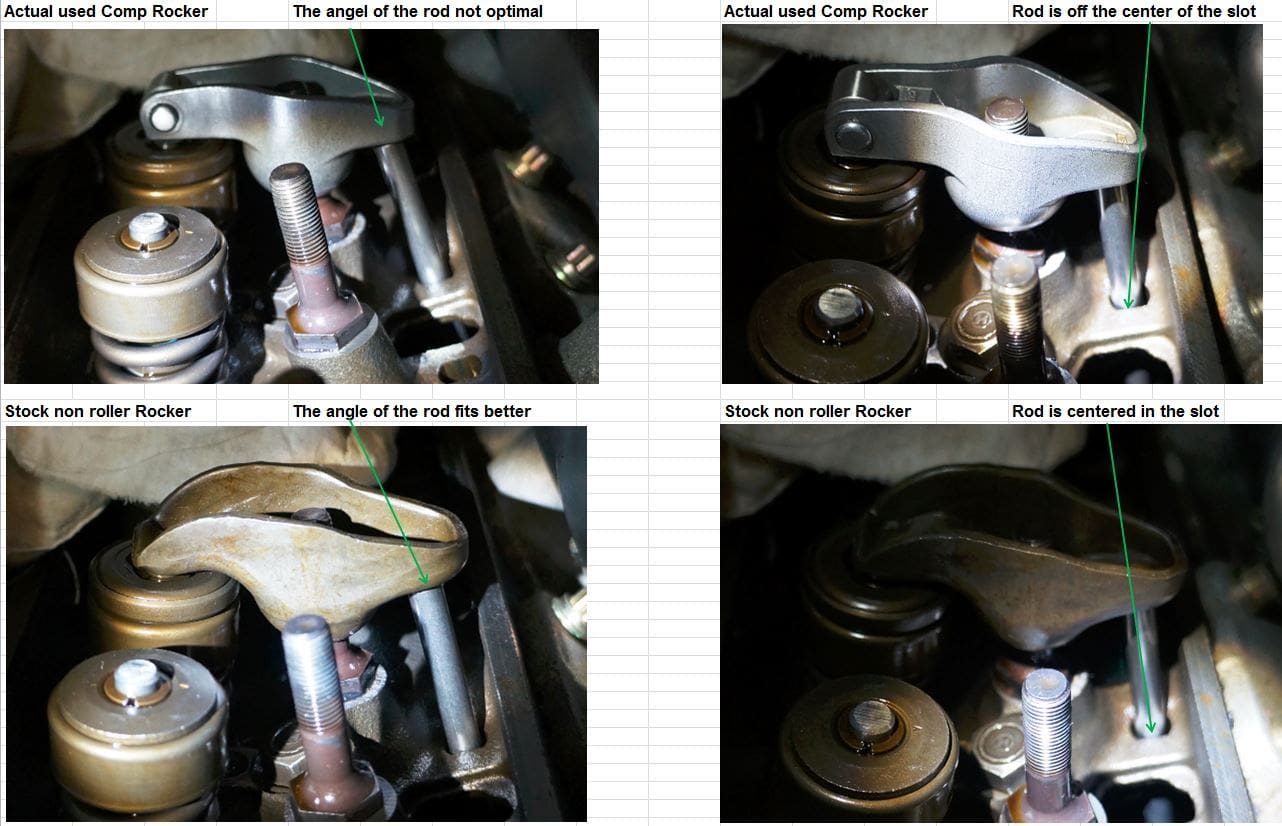

At the pictures above i used the comp magnum rockers (upper pictures) and the old stock GM rockers (lower pics) to illustrate the ange of the Pushrod with the rocker.

You can see that the geometry with the GM rockers is way better !!??

BTW the original non roller GM Rockers are also self aligning !

You can see that the geometry with the GM rockers is way better !!??

BTW the original non roller GM Rockers are also self aligning !

#24

Member

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

The engine is from 1989 and has hydraulic lifters, so the pushrods are equal on both sides.

I thighted the nut of the Rocker till there was no more movement of the rod, and then half a rotation more (i think thats correct).

I used the stock retainers (rotatator on exhaust), therfore the installes hight sould be stock.

Yes i cut down the guide boss to got proper clearance.

Installed height: At the exhaust side the height ist near perfect, but there is also damage !

I thighted the nut of the Rocker till there was no more movement of the rod, and then half a rotation more (i think thats correct).

I used the stock retainers (rotatator on exhaust), therfore the installes hight sould be stock.

Yes i cut down the guide boss to got proper clearance.

Installed height: At the exhaust side the height ist near perfect, but there is also damage !

I don't know how many times I've posted how to set pre-load.

To adjust lifter pre-load you must be on the base circle of the cam. You need to understand this not just assume you understand it. Please look it up until your convinced.

Next the best method I know of is to roll the p-rod with your fingers until you no longer can move it up or done but still roll it with your fingers - just a little drag but not stopped!

Then add 1 full turn of pre-load.

When I zoom in on these pictures (on tablet) I see damage to the tip of the valve stem (on valves with the rockers off of course). Looks like the rocker tips are slipping off the valve stem tip. The original head slots for the p-rods are not working well enough with the aftermarket rockers and block/head combination. You need a smooth sliding fit there for the full lift of the cam - no friction just smooth sliding between the p-rod and slots.

Also I see 2 different spring retainers. A different spring installed height on the exhaust than the intake. That has to affect geometry meaning you may need different length p-rods for the exhaust valves than what you have on the intake valves.

Please let us know what you find. It helps us all.

Last edited by cardo0; 07-09-2017 at 12:07 PM. Reason: Stupid autocorrect!

#25

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Seeing your actual valve springs as installed, is very informative.

You need to get rid of those "rotators" and the splash shields. Those are worthless and should never be put back in during a "rebuild". There should be NOTHING on top of the spring other than the retainer. You may find that the exhaust valves will need extra shims to make up for doing away with the useless dead-weight "rotators". I'd suggest buying 2 sets of the shims I linked for you, to make sure you have enough thickness available.

If those are the stock retainers, replace them with something better. Manley, Comp, or various other mfrs would be acceptable; Comp 742 https://www.summitracing.com/parts/cca-742-16 for example.

Use "positive" seals in the correct diameter for whatever your guides are now after being cut. If they're still stock diameter (0.570"), use stock replacement Fel-Pro ones. If they're some smaller diameter now, which would usually be either .500" or .530", use the Comp Teflon ones; part # will be either 510 or 503 depending on the size you need.

There's nothing inherently wrong with the angle that the Comp rocker is sitting at. In fact, with a cam that has higher lift than stock, that is inevitable. Regardless, getting the right length push rods will put the rockers at the angle they need to be at, even if it's considerably different from stock.

Ideally you should have one AND ONLY ONE method for alignment of the rockers to the valve stems. There are 3 methods available: the narrow slot holes in the heads, guide plates, and self-aligning rockers. If either the 2nd or 3rd method is used, then the holes in the heads MUST be opened up to allow the push rod to be located wherever the other alignment method wants it to be. The reason is, if you have more than one method and the methods conflict in where they try to locate them, the whole system will bind up and destroy parts, usually by either forcing the push rods out of the cup in the rocker (which is how yours appear to have failed), or bending the push rods, or gouging the side of the push rods where they pass through another part. You can sometimes get lucky but it's rare. (stock SA rockers, which have a VERY wide tip, aren't as picky as aftermarket ones) But even if the rockers were not damaged, you would still need to get NON-self-aligning ones to replace them. https://www.summitracing.com/parts/cca-1412-16 for ones exactly like what you have now except without the SA feature. The slots will then perform the alignment function, without conflicting with the "rails" on the rocker tip. This was the stock method before the change to self-aligning rocker in 87.

All 3 methods are effective. The slots in the heads are the weakest, as the cast-iron tends to wear and develop tolerance. But as long as your slots weren't damaged by the problem of having 2 alignment systems in effect at the same time, they'll work fine.

I don't see anything at all wrong with the valve stem tips. All I see is normal wear and witness marks.

Since you have hydraulic roller lifters, the push rods will not rotate in operation, or at least, only very little. Since the lifters don't rotate they won't be driving the push rods to rotate.

Correct adjustment is, tighten the rocker nut until all VERTICAL play in the push rod is taken up; then add your desired preload. DO NOT use the "twist the push rod" method!!! You will surely end up with too much preload. Look for zero VERTICAL play ONLY!!! ½ turn of preload is OK. Recommendations are usually something like, 1 turn if all-new in a stock motor and you don't want to touch them for 200,000 km; ¾ turn for a used motor; ½ turn for typical street performance use; or ¼ turn or even less for race-only.

You need to get rid of those "rotators" and the splash shields. Those are worthless and should never be put back in during a "rebuild". There should be NOTHING on top of the spring other than the retainer. You may find that the exhaust valves will need extra shims to make up for doing away with the useless dead-weight "rotators". I'd suggest buying 2 sets of the shims I linked for you, to make sure you have enough thickness available.

If those are the stock retainers, replace them with something better. Manley, Comp, or various other mfrs would be acceptable; Comp 742 https://www.summitracing.com/parts/cca-742-16 for example.

Use "positive" seals in the correct diameter for whatever your guides are now after being cut. If they're still stock diameter (0.570"), use stock replacement Fel-Pro ones. If they're some smaller diameter now, which would usually be either .500" or .530", use the Comp Teflon ones; part # will be either 510 or 503 depending on the size you need.

There's nothing inherently wrong with the angle that the Comp rocker is sitting at. In fact, with a cam that has higher lift than stock, that is inevitable. Regardless, getting the right length push rods will put the rockers at the angle they need to be at, even if it's considerably different from stock.

Ideally you should have one AND ONLY ONE method for alignment of the rockers to the valve stems. There are 3 methods available: the narrow slot holes in the heads, guide plates, and self-aligning rockers. If either the 2nd or 3rd method is used, then the holes in the heads MUST be opened up to allow the push rod to be located wherever the other alignment method wants it to be. The reason is, if you have more than one method and the methods conflict in where they try to locate them, the whole system will bind up and destroy parts, usually by either forcing the push rods out of the cup in the rocker (which is how yours appear to have failed), or bending the push rods, or gouging the side of the push rods where they pass through another part. You can sometimes get lucky but it's rare. (stock SA rockers, which have a VERY wide tip, aren't as picky as aftermarket ones) But even if the rockers were not damaged, you would still need to get NON-self-aligning ones to replace them. https://www.summitracing.com/parts/cca-1412-16 for ones exactly like what you have now except without the SA feature. The slots will then perform the alignment function, without conflicting with the "rails" on the rocker tip. This was the stock method before the change to self-aligning rocker in 87.

All 3 methods are effective. The slots in the heads are the weakest, as the cast-iron tends to wear and develop tolerance. But as long as your slots weren't damaged by the problem of having 2 alignment systems in effect at the same time, they'll work fine.

I don't see anything at all wrong with the valve stem tips. All I see is normal wear and witness marks.

Since you have hydraulic roller lifters, the push rods will not rotate in operation, or at least, only very little. Since the lifters don't rotate they won't be driving the push rods to rotate.

Correct adjustment is, tighten the rocker nut until all VERTICAL play in the push rod is taken up; then add your desired preload. DO NOT use the "twist the push rod" method!!! You will surely end up with too much preload. Look for zero VERTICAL play ONLY!!! ½ turn of preload is OK. Recommendations are usually something like, 1 turn if all-new in a stock motor and you don't want to touch them for 200,000 km; ¾ turn for a used motor; ½ turn for typical street performance use; or ¼ turn or even less for race-only.

Last edited by sofakingdom; 07-09-2017 at 01:03 PM.

#26

Supreme Member

iTrader: (1)

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Wouldn't it be important to insure the lifter is fully inflated prior to setting the preload? Otherwise you will further compress an already preloaded lifter yes? Isn't the idea of adjusting them while running to allow them to fully inflate when you back them off and then tighten till you stop hearing noise + half a turn (or whatever).

Otherwise manual inflation? Can you use an oil pre-luber with shop air to inflate them with the rockers loose? Would that be effective on the GM lifter design?

GD

Otherwise manual inflation? Can you use an oil pre-luber with shop air to inflate them with the rockers loose? Would that be effective on the GM lifter design?

GD

#27

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

There's a spring inside of them, that tries to fully extend them... and yes you're right both about the result of error in finding "zero", and about the "running" method. Oil pressure of course assists the spring in pushing the push rod seat all the way up against the wire retainer. Adding preload after the plunger is already partway depressed is precisely the error that the "twist the push rod" thing introduces, since it's VERY difficult to locate zero play by that method. I suppose somebody that did it all the time and built ALOT of motors might be able to gauge it accurately, but for a novice, it's a guarantee of screwing up. I don't even feel comfortable trying to use it myself even after years of running solid cams and being REAL used to what valve lash feels like.

#28

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Hello cardo0

I dont understand what you mean with different P-Rod lengths (exhaust and inlet).

The valves have all the same length and the seat is at the same location, therfore the geometry is exact the same. Only the preload is different.

I dont understand what you mean with different P-Rod lengths (exhaust and inlet).

The valves have all the same length and the seat is at the same location, therfore the geometry is exact the same. Only the preload is different.

#29

Supreme Member

iTrader: (1)

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

I used the push/pull method when installing new 1.6 roller rockers and then still had a few that made noise and had to go back in an add a little preload to them. But since I wasn't using the running method I figured I would get some of the preload from the original setting and didnt want to add much more. I gave them about 1/4 turn past what I felt was zero. I had clatter on two or three and adjusted that out after a run in to settle everything and wash out the assembly lube, etc.

Seems to be working fine FWIW.

GD

Seems to be working fine FWIW.

GD

#30

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Intake and exhaust lift is different at my cam, so what is of more importance ?

Equal seat or open pressures ?

Comp Info for my cam : 120 - 145 lbs seat P

Is there a general problem with my configuration 154lbs intake seat P and 138lbs exhaust seat P ?

Equal seat or open pressures ?

Comp Info for my cam : 120 - 145 lbs seat P

Is there a general problem with my configuration 154lbs intake seat P and 138lbs exhaust seat P ?

#31

Member

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Ya know i think your right now. Use that ProForm checking tool - that will tell the truth. Anything close is good enough as they only sell p-rods in like increments of 0.020" on the shelf anyways unless you buy custom length p-rods.

I'm seeing shiny like new exposed metal on the vlv tips edges. Can't explain why others don't.

Adjust the preload at zero lash. Myself I like to roll the p-rod to tell me I haven't compressed the lifter plunger at all. Using just the up and down check can work great too. But many times the rocker arm wiggles and fools the owner into adding to much pre-load at zero lash. To each s own.

One full turn of pre-load reduces the max travel of the lifters internal plunger creating more lift and more power than less pre-load. It also allows for more wear in the entire valve train as engine use/mileage increases.

Using less pre-load is and old racers trick that prevents the valve becoming held open at high RPM where the lifter cannot bleed down fast enough and the lifter pumps up plunger to the top and holds the vlv open when the lifter is off the ramp of the cam lobe. So no matter how little pre-load you use if the lifter pumps up it will still hold the vlv open by that amount.

Never over-rev your engine and you don't have to worry about lifter pump - up.

Hope this explains a few things for you.

#32

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

I think it would be better to switch from the "High Energy" Pushrods (made of steel) to the Magnum Pushrods (made of Chromoly).

#33

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

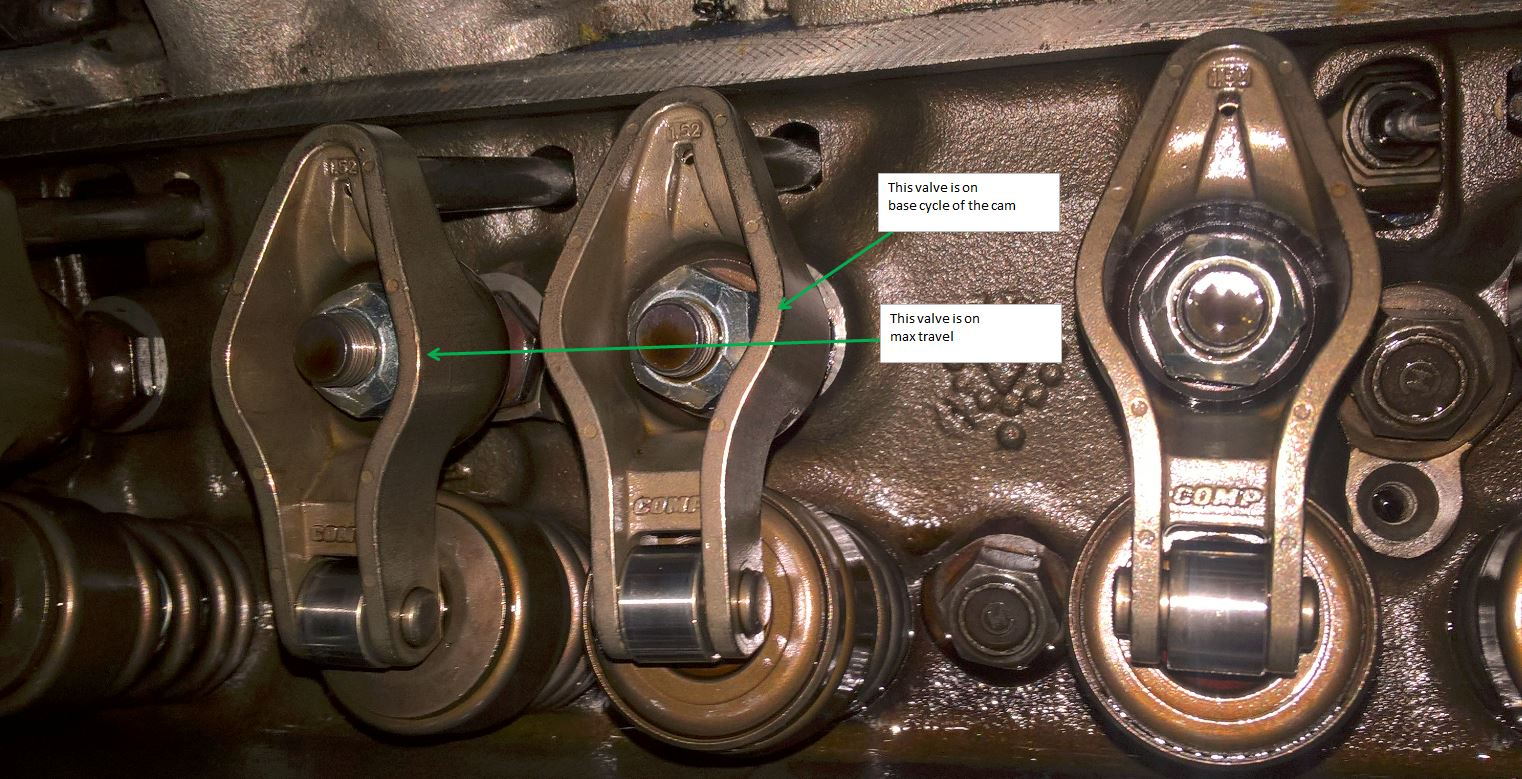

This is what you need to achieve.

#34

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

GREAT answer/explanation in post #25 sofa.

#35

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

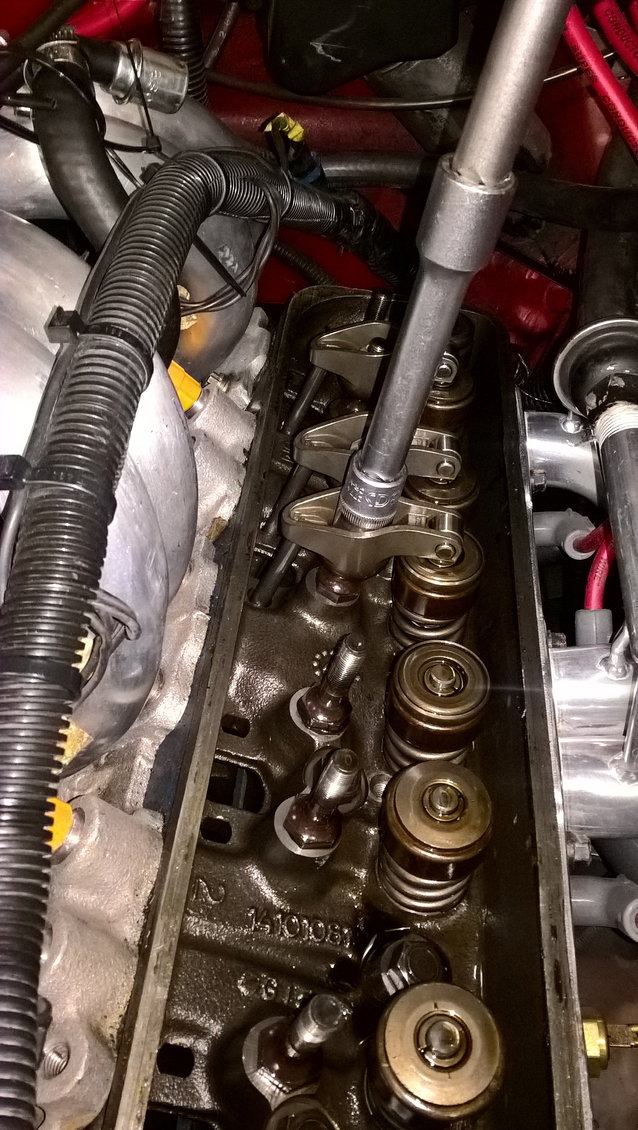

Here are a few more pictures that may help you.

They are from my 334 SBC with ISKY HFT camshaft.

You can see the paint lines on the pushrods to check for rotation.

Yours will not rotate like mine have to because you have a roller camshaft.

Ignore my pushrod length. Yours will be shorter because of your roller lifters.

They are from my 334 SBC with ISKY HFT camshaft.

You can see the paint lines on the pushrods to check for rotation.

Yours will not rotate like mine have to because you have a roller camshaft.

Ignore my pushrod length. Yours will be shorter because of your roller lifters.

#36

Supreme Member

iTrader: (1)

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Modified valve cover for setting lash? Nice. I'm totally going to do that. I feel that the running method is the only really good way to FOR SURE find zero and set the preload.

I'm not comfortable with the whole 1/4, 1/2, 3/4, 1 turn, seat of the pant adjustment. Everyone seems to have a different rule of thumb.... I would like to know what the actual lifter plunger throw is, and do the geometry to find out how much it actually moves the plunger per 1/4 turn so I can set it at half it's travel after I find EXACTLY zero with it running.

GD

I'm not comfortable with the whole 1/4, 1/2, 3/4, 1 turn, seat of the pant adjustment. Everyone seems to have a different rule of thumb.... I would like to know what the actual lifter plunger throw is, and do the geometry to find out how much it actually moves the plunger per 1/4 turn so I can set it at half it's travel after I find EXACTLY zero with it running.

GD

#37

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

A have a few questions about springs.:

This is no race configuration, its only a engine to have fun at the street.

1.) What is the problem with the rotator style stock retainer and the splash shield ?

2.) Is there a problem with the different Seat pressures (intake 154lbs, ex 138lbs) ?

I could remove the umbrellas at the inake to come down to ~ 145lbs ?

3.)What can i do to remove all metal shavings ? I hope my new oil pump is still ok.

4.) Is it better to have equal seat pressure or open pressure ?

Thank you very much, this conversation is very helpful for me !

This is no race configuration, its only a engine to have fun at the street.

1.) What is the problem with the rotator style stock retainer and the splash shield ?

2.) Is there a problem with the different Seat pressures (intake 154lbs, ex 138lbs) ?

I could remove the umbrellas at the inake to come down to ~ 145lbs ?

3.)What can i do to remove all metal shavings ? I hope my new oil pump is still ok.

4.) Is it better to have equal seat pressure or open pressure ?

Thank you very much, this conversation is very helpful for me !

#38

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Seeing your actual valve springs as installed, is very informative.

You need to get rid of those "rotators" and the splash shields. Those are worthless and should never be put back in during a "rebuild". There should be NOTHING on top of the spring other than the retainer. You may find that the exhaust valves will need extra shims to make up for doing away with the useless dead-weight "rotators". I'd suggest buying 2 sets of the shims I linked for you, to make sure you have enough thickness available.

If those are the stock retainers, replace them with something better. Manley, Comp, or various other mfrs would be acceptable; Comp 742 https://www.summitracing.com/parts/cca-742-16 for example.

Use "positive" seals in the correct diameter for whatever your guides are now after being cut. If they're still stock diameter (0.570"), use stock replacement Fel-Pro ones. If they're some smaller diameter now, which would usually be either .500" or .530", use the Comp Teflon ones; part # will be either 510 or 503 depending on the size you need.

There's nothing inherently wrong with the angle that the Comp rocker is sitting at. In fact, with a cam that has higher lift than stock, that is inevitable. Regardless, getting the right length push rods will put the rockers at the angle they need to be at, even if it's considerably different from stock.

Ideally you should have one AND ONLY ONE method for alignment of the rockers to the valve stems. There are 3 methods available: the narrow slot holes in the heads, guide plates, and self-aligning rockers. If either the 2nd or 3rd method is used, then the holes in the heads MUST be opened up to allow the push rod to be located wherever the other alignment method wants it to be. The reason is, if you have more than one method and the methods conflict in where they try to locate them, the whole system will bind up and destroy parts, usually by either forcing the push rods out of the cup in the rocker (which is how yours appear to have failed), or bending the push rods, or gouging the side of the push rods where they pass through another part. You can sometimes get lucky but it's rare. (stock SA rockers, which have a VERY wide tip, aren't as picky as aftermarket ones) But even if the rockers were not damaged, you would still need to get NON-self-aligning ones to replace them. https://www.summitracing.com/parts/cca-1412-16 for ones exactly like what you have now except without the SA feature. The slots will then perform the alignment function, without conflicting with the "rails" on the rocker tip. This was the stock method before the change to self-aligning rocker in 87.

All 3 methods are effective. The slots in the heads are the weakest, as the cast-iron tends to wear and develop tolerance. But as long as your slots weren't damaged by the problem of having 2 alignment systems in effect at the same time, they'll work fine.

I don't see anything at all wrong with the valve stem tips. All I see is normal wear and witness marks.

Since you have hydraulic roller lifters, the push rods will not rotate in operation, or at least, only very little. Since the lifters don't rotate they won't be driving the push rods to rotate.

Correct adjustment is, tighten the rocker nut until all VERTICAL play in the push rod is taken up; then add your desired preload. DO NOT use the "twist the push rod" method!!! You will surely end up with too much preload. Look for zero VERTICAL play ONLY!!! ½ turn of preload is OK. Recommendations are usually something like, 1 turn if all-new in a stock motor and you don't want to touch them for 200,000 km; ¾ turn for a used motor; ½ turn for typical street performance use; or ¼ turn or even less for race-only.

You need to get rid of those "rotators" and the splash shields. Those are worthless and should never be put back in during a "rebuild". There should be NOTHING on top of the spring other than the retainer. You may find that the exhaust valves will need extra shims to make up for doing away with the useless dead-weight "rotators". I'd suggest buying 2 sets of the shims I linked for you, to make sure you have enough thickness available.

If those are the stock retainers, replace them with something better. Manley, Comp, or various other mfrs would be acceptable; Comp 742 https://www.summitracing.com/parts/cca-742-16 for example.

Use "positive" seals in the correct diameter for whatever your guides are now after being cut. If they're still stock diameter (0.570"), use stock replacement Fel-Pro ones. If they're some smaller diameter now, which would usually be either .500" or .530", use the Comp Teflon ones; part # will be either 510 or 503 depending on the size you need.

There's nothing inherently wrong with the angle that the Comp rocker is sitting at. In fact, with a cam that has higher lift than stock, that is inevitable. Regardless, getting the right length push rods will put the rockers at the angle they need to be at, even if it's considerably different from stock.

Ideally you should have one AND ONLY ONE method for alignment of the rockers to the valve stems. There are 3 methods available: the narrow slot holes in the heads, guide plates, and self-aligning rockers. If either the 2nd or 3rd method is used, then the holes in the heads MUST be opened up to allow the push rod to be located wherever the other alignment method wants it to be. The reason is, if you have more than one method and the methods conflict in where they try to locate them, the whole system will bind up and destroy parts, usually by either forcing the push rods out of the cup in the rocker (which is how yours appear to have failed), or bending the push rods, or gouging the side of the push rods where they pass through another part. You can sometimes get lucky but it's rare. (stock SA rockers, which have a VERY wide tip, aren't as picky as aftermarket ones) But even if the rockers were not damaged, you would still need to get NON-self-aligning ones to replace them. https://www.summitracing.com/parts/cca-1412-16 for ones exactly like what you have now except without the SA feature. The slots will then perform the alignment function, without conflicting with the "rails" on the rocker tip. This was the stock method before the change to self-aligning rocker in 87.

All 3 methods are effective. The slots in the heads are the weakest, as the cast-iron tends to wear and develop tolerance. But as long as your slots weren't damaged by the problem of having 2 alignment systems in effect at the same time, they'll work fine.

I don't see anything at all wrong with the valve stem tips. All I see is normal wear and witness marks.

Since you have hydraulic roller lifters, the push rods will not rotate in operation, or at least, only very little. Since the lifters don't rotate they won't be driving the push rods to rotate.

Correct adjustment is, tighten the rocker nut until all VERTICAL play in the push rod is taken up; then add your desired preload. DO NOT use the "twist the push rod" method!!! You will surely end up with too much preload. Look for zero VERTICAL play ONLY!!! ½ turn of preload is OK. Recommendations are usually something like, 1 turn if all-new in a stock motor and you don't want to touch them for 200,000 km; ¾ turn for a used motor; ½ turn for typical street performance use; or ¼ turn or even less for race-only.

Now i am a litte bit confused.

Today i looked at Summit for the correct parts.

But !

There are no Rockers availabe for my 1989 Engine without self aligning style. All Rockers without self aligning style can be used up to 1986. Is it possible that you are wrong at this point and my engine needs the self aligning type and has the narrow slots in the head ?

#39

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Many different design heads will bolt on your block. Many aftermarket heads listed for use with various years will have different designs.

The most critical element of this is that there should only be ONE guide method employed - Guide slots machined in the heads, guide plates bolted under the rocker studs, or self-aligning rockers.

1987 and later OEM heads have large clearance holes which come nowhere near the push rods, and rely upon the rockers for alignment. The heads shown in your photos appear to be pre-1987 design. If that is the case, pre-1987 rockers (not self-aligning) should be used. If the heads previously had clearance and you installed larger diameter push rods, those holes should have been enlarged.

The most critical element of this is that there should only be ONE guide method employed - Guide slots machined in the heads, guide plates bolted under the rocker studs, or self-aligning rockers.

1987 and later OEM heads have large clearance holes which come nowhere near the push rods, and rely upon the rockers for alignment. The heads shown in your photos appear to be pre-1987 design. If that is the case, pre-1987 rockers (not self-aligning) should be used. If the heads previously had clearance and you installed larger diameter push rods, those holes should have been enlarged.

#40

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Thanks 84, I always try to avoid the "I always heard" or "it just works for me" type explanations and instead point out what's really going on, so that people understand WHY rather than just blindly obeying.

1. The rotator and splash shield are just dead weight, at one of the worst possible places to have that in an engine; they don't really "do" anything.

2. Seat pressures will become the same when the installed height is correctly set to 1.750" ±.015" or so, since then they will all be the same height.

3. Depends on where the metal shavings are... you might be able to clean up under the valve covers with a magnet, but the rest of the engine, there's not much you can do. Fortunately most of that debris should settle out and stay put wherever it lies, and not circulate in the oil.

4. "Equal pressure" by itself doesn't matter. What matters is having the installed height set correctly so that the spring is operated within the range it is designed for. "Equal pressure" at the seat will follow as a natural consequence of this.

The difference between 87-up and 86-back rockers is precisely the difference between SA and non-SA. Looking parts up for your car by year will return SA ones. But that's not what you need, since you have the narrow slots in your heads; you really need the early-model ones to go with the early-model feature that your heads are equipped with. And no, it is not possible that your engine needs 2 conflicting alignment methods.

Disorder, most lifters have around .080 - .100" of plunger travel. Since the thread pitch on the rocker nuts is 24/inch, each full turn of the nut depresses the rocker pivot about .042". Then, for a 1.5 ratio rocker (stock SBC), the push rod end of it is depressed about 2.5 ÷ 1.5 × .042" per turn, or, just about .070". IOW one full turn takes just about all of it up, and ½ turn puts it roughly in the center. Consider though that a BBC uses the same lifters but has 1.6 ratio stock. But the purpose of hydraulic lifters in the first place is to eliminate the need for precision rocker adjustment. It's just supposed to put the plunger somewhere into the correct range. Consider also, all of the engine designs in the world with a non-adjustable valve train, that still work just fine, such as Pontiac V8 or the LSx series or Gen 6 BBC, all of which also use the same part # lifters as SBCs did in the same years.

You don't necessarily want to take up all the plunger travel though. If the valves float AT ALL EVER, then during that time in which the spring pressure on the valve train goes completely away, the plunger will extend itself aka "pump-up", and the valves won't be able to close properly when everything settles back down. This is why, for high-RPM use, less preload or even near zero is recommended. The downside of that is, they may need to be adjusted more often, as parts wear and the preload goes away (or if it increases, which happens if the valves and seats wear more than the push rods and rocker *****).

IMO it's more important in a street motor that they all be the same, than the exact amount they're set to, within reason. For a motor with TPI on it, which by definition won't ever see high enough RPMs for all of that to matter, ½ to ¾ turn is probably best.

And I completely agree that if practical, setting it with the engine running is the best way to do it, as long as it's set close enough during assembly for the engine to run in the first place. Which the way I like to do it is, set all 16 as quickly as possible to zero lash (where they have just quit clacking), then shut the motor off, add the desired preload to all 16, and put the VCs back on. I don't try to add the preload while the engine is still running because that stretches the process out so long. I don't fool around with modified VCs myself since I don't mind taking a trip to the quarter car wash afterwards to clean up any oil that escapes.

Cardo, what I see on the valve stems, that may be what you're interpreting as wear, is a chamfer around the edge of the stem surface that looks like it was deliberately put there. I don't see any kind of significant wear.

1. The rotator and splash shield are just dead weight, at one of the worst possible places to have that in an engine; they don't really "do" anything.

2. Seat pressures will become the same when the installed height is correctly set to 1.750" ±.015" or so, since then they will all be the same height.

3. Depends on where the metal shavings are... you might be able to clean up under the valve covers with a magnet, but the rest of the engine, there's not much you can do. Fortunately most of that debris should settle out and stay put wherever it lies, and not circulate in the oil.

4. "Equal pressure" by itself doesn't matter. What matters is having the installed height set correctly so that the spring is operated within the range it is designed for. "Equal pressure" at the seat will follow as a natural consequence of this.

The difference between 87-up and 86-back rockers is precisely the difference between SA and non-SA. Looking parts up for your car by year will return SA ones. But that's not what you need, since you have the narrow slots in your heads; you really need the early-model ones to go with the early-model feature that your heads are equipped with. And no, it is not possible that your engine needs 2 conflicting alignment methods.

Disorder, most lifters have around .080 - .100" of plunger travel. Since the thread pitch on the rocker nuts is 24/inch, each full turn of the nut depresses the rocker pivot about .042". Then, for a 1.5 ratio rocker (stock SBC), the push rod end of it is depressed about 2.5 ÷ 1.5 × .042" per turn, or, just about .070". IOW one full turn takes just about all of it up, and ½ turn puts it roughly in the center. Consider though that a BBC uses the same lifters but has 1.6 ratio stock. But the purpose of hydraulic lifters in the first place is to eliminate the need for precision rocker adjustment. It's just supposed to put the plunger somewhere into the correct range. Consider also, all of the engine designs in the world with a non-adjustable valve train, that still work just fine, such as Pontiac V8 or the LSx series or Gen 6 BBC, all of which also use the same part # lifters as SBCs did in the same years.

You don't necessarily want to take up all the plunger travel though. If the valves float AT ALL EVER, then during that time in which the spring pressure on the valve train goes completely away, the plunger will extend itself aka "pump-up", and the valves won't be able to close properly when everything settles back down. This is why, for high-RPM use, less preload or even near zero is recommended. The downside of that is, they may need to be adjusted more often, as parts wear and the preload goes away (or if it increases, which happens if the valves and seats wear more than the push rods and rocker *****).

IMO it's more important in a street motor that they all be the same, than the exact amount they're set to, within reason. For a motor with TPI on it, which by definition won't ever see high enough RPMs for all of that to matter, ½ to ¾ turn is probably best.

And I completely agree that if practical, setting it with the engine running is the best way to do it, as long as it's set close enough during assembly for the engine to run in the first place. Which the way I like to do it is, set all 16 as quickly as possible to zero lash (where they have just quit clacking), then shut the motor off, add the desired preload to all 16, and put the VCs back on. I don't try to add the preload while the engine is still running because that stretches the process out so long. I don't fool around with modified VCs myself since I don't mind taking a trip to the quarter car wash afterwards to clean up any oil that escapes.

Cardo, what I see on the valve stems, that may be what you're interpreting as wear, is a chamfer around the edge of the stem surface that looks like it was deliberately put there. I don't see any kind of significant wear.

Last edited by sofakingdom; 07-10-2017 at 07:52 AM.

#41

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

A have a few questions about springs.:

This is no race configuration, its only a engine to have fun at the street.

1.) What is the problem with the rotator style stock retainer and the splash shield ?

2.) Is there a problem with the different Seat pressures (intake 154lbs, ex 138lbs) ?

I could remove the umbrellas at the inake to come down to ~ 145lbs ?

3.)What can i do to remove all metal shavings ? I hope my new oil pump is still ok.

4.) Is it better to have equal seat pressure or open pressure ?

Thank you very much, this conversation is very helpful for me !

This is no race configuration, its only a engine to have fun at the street.

1.) What is the problem with the rotator style stock retainer and the splash shield ?

2.) Is there a problem with the different Seat pressures (intake 154lbs, ex 138lbs) ?

I could remove the umbrellas at the inake to come down to ~ 145lbs ?

3.)What can i do to remove all metal shavings ? I hope my new oil pump is still ok.

4.) Is it better to have equal seat pressure or open pressure ?

Thank you very much, this conversation is very helpful for me !

- [*]

- [*]

- [*]

Last edited by Vader; 07-10-2017 at 07:43 AM.

#43

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

You just gotta get a faster keyboard!!!

#44

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Now i have 2 possibilities.:

1.) Buy the same rockers and use magnum pushrods (they are also Chromoly)

2.) Change to full rollers (comp 19017-1) They are designed to fit my centerbolt heads

I think number 2 is the better solution.

Is there anything to concern ?

1.) Buy the same rockers and use magnum pushrods (they are also Chromoly)

2.) Change to full rollers (comp 19017-1) They are designed to fit my centerbolt heads

I think number 2 is the better solution.

Is there anything to concern ?

#45

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Many different design heads will bolt on your block. Many aftermarket heads listed for use with various years will have different designs.

The most critical element of this is that there should only be ONE guide method employed - Guide slots machined in the heads, guide plates bolted under the rocker studs, or self-aligning rockers.

1987 and later OEM heads have large clearance holes which come nowhere near the push rods, and rely upon the rockers for alignment. The heads shown in your photos appear to be pre-1987 design. If that is the case, pre-1987 rockers (not self-aligning) should be used. If the heads previously had clearance and you installed larger diameter push rods, those holes should have been enlarged.

The most critical element of this is that there should only be ONE guide method employed - Guide slots machined in the heads, guide plates bolted under the rocker studs, or self-aligning rockers.

1987 and later OEM heads have large clearance holes which come nowhere near the push rods, and rely upon the rockers for alignment. The heads shown in your photos appear to be pre-1987 design. If that is the case, pre-1987 rockers (not self-aligning) should be used. If the heads previously had clearance and you installed larger diameter push rods, those holes should have been enlarged.

My car is from 1989 and the engine was never opened. Therfore this heads are stock and they have those aligning holes.

A litte bit confusing.

#46

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,051

Received 1,672 Likes

on

1,269 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

GM did that strange thing for a couple of years, where they applied the early-model machine work to the heads, but put the late-model rockers on them. Gotta love that "quality control".

Since you have to buy rockers and push rods anyway, you might as well get the good rockers. I'd suggest their "High Tech" push rods rather than the Magnum though. Not too much more $$$ (or £££ or ¥¥¥ or €€€ or whatever) than the other, but a MUCH better part. https://www.summitracing.com/parts/c...5-16/overview/ for example. (length yet to be determined)

Since you have to buy rockers and push rods anyway, you might as well get the good rockers. I'd suggest their "High Tech" push rods rather than the Magnum though. Not too much more $$$ (or £££ or ¥¥¥ or €€€ or whatever) than the other, but a MUCH better part. https://www.summitracing.com/parts/c...5-16/overview/ for example. (length yet to be determined)

#47

Supreme Member

iTrader: (1)

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Since you have the broached push rod holes you can just use non self-aligning rockers I would assume. I've heard it said that GM claims self-aligning rockers (87+ new style) are backwards compatible back to '55.

And yeah they did that stock for some reason - self aligning rockers with broached push-rod-alignment style holes in the heads. It's confusing but it is stock.

GD

And yeah they did that stock for some reason - self aligning rockers with broached push-rod-alignment style holes in the heads. It's confusing but it is stock.

GD

#48

Member

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

I get the impression the block was decked some amount and/or heads were shaved enough to ruin the p-rod clearance through the head slots. You need to get that clearance correct before any new parts will work. It may require removing the heads to open up the slots unless you feel confident enough to operate with the heads on.

Myself, for that motor I would use the inexpensive generic/copy cat Summit parts - roller tip rockers, hardened p-rods, spring retainers.

One more thing, you just need enough seat pressure to shut the valve at RPM. Anymore will just help it but does add stress to the valve train. I wouldn't lose any sleep over 10 or 20 psi extra pressure.

Last edited by cardo0; 07-10-2017 at 09:28 PM. Reason: Add pronoun.

#49

Supreme Member

iTrader: (1)

Join Date: Feb 2017

Location: Meriden, CT 06450

Posts: 4,030

Received 511 Likes

on

428 Posts

Car: 84 TA orig. 305 LG4 "H" E4ME

Engine: 334 SBC - stroked 305 M4ME Q-Jet

Transmission: upgraded 700R4 3200 stall

Axle/Gears: 10bolt 4.10 Posi w Lakewood TA Bars

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

And I completely agree that if practical, setting it with the engine running is the best way to do it, as long as it's set close enough during assembly for the engine to run in the first place. Which the way I like to do it is, set all 16 as quickly as possible to zero lash (where they have just quit clacking), then shut the motor off, add the desired preload to all 16, and put the VCs back on. I don't try to add the preload while the engine is still running because that stretches the process out so long.

Good idea there, sofa.

GM's original intent for the exhaust valve rotator was for low rpm truck engines to help prevent valve seat recession. It seems that they just got installed on every head from the era. No longer a problem with induction-hardened valve seats.

The splash shields are no longer necessary with modern valve seals. Remember, these were used with only an o-ring for a seal. Get rid of them Zylinder. Also go with heat-treated & hardened chromoly pushrods (final length to be determined after measuring). Then you do not need to worry about whichever method you choose for guiding the rockers. Besides, they are stiffer. Get 1-piece pushrods, not the ones with pressed-in tips, whatever brand you choose. I like Trick Flow. Excellent piece and reasonable price. You should buy the CompCams 1412-16 roller tip rockers - 3/8" stud, 1.52 ratio, not self-aligning and use the slots in the heads for guiding. Your setup will be nearly the same as mine pictured in post #35.

SmCo magnets can help remove any metal shavings that might be circulating in your oil. Put one each of these near the oil drainback holes in your heads under the valvecovers. If you heads were aluminum, use JB Weld to epoxy in place. These are good to 572 degrees F and have over a 5# pull. http://www.magnet4sale.com/smco-magn...f-temperature/

And you can make your own very powerful oil drain plug magnet by drilling a 1/4" hole in your stock drain plug (lathe) and red loctiting one of these magnets in there (over 4# pull). http://www.magnet4sale.com/smco-magn...f-temperature/

This will be way more powerful than the cheap magnetic drain plugs you can buy.

As far as your spring and retainer setup is concerned, give a call to Alex's Parts. Great guy, he will help you. He has kits specifically designed for Vortec heads. Here is an example: https://www.alexsparts.com/valve-spr...seat-pressure/

I am using his parts on a 302 Chevy that spins over 8000 rpm.

Good idea there, sofa.

GM's original intent for the exhaust valve rotator was for low rpm truck engines to help prevent valve seat recession. It seems that they just got installed on every head from the era. No longer a problem with induction-hardened valve seats.

The splash shields are no longer necessary with modern valve seals. Remember, these were used with only an o-ring for a seal. Get rid of them Zylinder. Also go with heat-treated & hardened chromoly pushrods (final length to be determined after measuring). Then you do not need to worry about whichever method you choose for guiding the rockers. Besides, they are stiffer. Get 1-piece pushrods, not the ones with pressed-in tips, whatever brand you choose. I like Trick Flow. Excellent piece and reasonable price. You should buy the CompCams 1412-16 roller tip rockers - 3/8" stud, 1.52 ratio, not self-aligning and use the slots in the heads for guiding. Your setup will be nearly the same as mine pictured in post #35.

SmCo magnets can help remove any metal shavings that might be circulating in your oil. Put one each of these near the oil drainback holes in your heads under the valvecovers. If you heads were aluminum, use JB Weld to epoxy in place. These are good to 572 degrees F and have over a 5# pull. http://www.magnet4sale.com/smco-magn...f-temperature/

And you can make your own very powerful oil drain plug magnet by drilling a 1/4" hole in your stock drain plug (lathe) and red loctiting one of these magnets in there (over 4# pull). http://www.magnet4sale.com/smco-magn...f-temperature/

This will be way more powerful than the cheap magnetic drain plugs you can buy.

As far as your spring and retainer setup is concerned, give a call to Alex's Parts. Great guy, he will help you. He has kits specifically designed for Vortec heads. Here is an example: https://www.alexsparts.com/valve-spr...seat-pressure/

I am using his parts on a 302 Chevy that spins over 8000 rpm.

Last edited by NoEmissions84TA; 07-11-2017 at 02:28 AM.

#50

Re: 1989 305 TPI problems with pushrods and rockers after bebuild

Ok, i use the non self aligning comp roller tip rockers.

Is the geometry equal to my self aligning ones ?

Than i can choose the correct pushrod lenth now and i can buy all together.

Each delivery ist very expensive here in the "old world".

For the Pushrods i have 3 items.:

-CCA-7608-16 Magnum Pushrods 105$

-CCA-7940-16 Hi-Tech Pushrods 142$

-CCA-8403-16 Hi-Tech Pushrods 197$

I dont see any difference between the last 2 items ????????

Is the geometry equal to my self aligning ones ?

Than i can choose the correct pushrod lenth now and i can buy all together.

Each delivery ist very expensive here in the "old world".

For the Pushrods i have 3 items.:

-CCA-7608-16 Magnum Pushrods 105$

-CCA-7940-16 Hi-Tech Pushrods 142$

-CCA-8403-16 Hi-Tech Pushrods 197$

I dont see any difference between the last 2 items ????????