torque arm problem

#1

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

torque arm problem

well i pulled out of the driveway and heard a noise like something scraping let off the gas heard a clunk so i turned around since i wasn't half a mile from the house. After going over everything i come to the front torque arm mount, bolt was out but still in the clamp. So i finally get it back in and it wont tighten up, so whoever put the poly mounts on my car was a ****ing moron and over tightened the bolt that goes into a aluminum transmission. Its holds a little but if it goes any tighter it slips. So what can i do? do i have to drop the transmission and tap the hole for a bigger bolt? heicoil?

Anyone had this happen before? how did u fix it?

Anyone had this happen before? how did u fix it?

Last edited by Seanmay1; 01-16-2010 at 12:55 AM.

#2

Senior Member

Join Date: Jul 2006

Location: Warrenton, VA

Posts: 615

Likes: 0

Received 1 Like

on

1 Post

Car: 1987 Camaro IROC-Z

Engine: LS1

Transmission: LS1 T56

Axle/Gears: Richmond 3.73

Re: torque arm problem

try to re tap it or heelicoil. if not get a trans crossmember that have the arm bolt to it.

#3

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

#4

Supreme Member

iTrader: (1)

Join Date: Sep 2008

Location: Western WA

Posts: 1,347

Likes: 0

Received 1 Like

on

1 Post

Car: 85 Camaro

Engine: No

Transmission: No

Axle/Gears: No

Re: torque arm problem

I don't think there are any bolts that thread in to the transmission, they just go through it, and have a nut on the other end.

#6

Supreme Member

iTrader: (3)

Join Date: May 2008

Location: boise, ID

Posts: 1,116

Likes: 0

Received 1 Like

on

1 Post

Car: 91 B4C "police special service"

Engine: L98 494hp

Transmission: tko-600 on order

Axle/Gears: 3.23 true trac

Re: torque arm problem

I think my has nuts and bolts, like gregs....I'll crawl under in a second and check.

But anyway, helicoil should work. Crossmember with torque arm mount would be even better. I know UMI performance has some. http://www.umiperformance.com/catalo...roducts_id=298

But anyway, helicoil should work. Crossmember with torque arm mount would be even better. I know UMI performance has some. http://www.umiperformance.com/catalo...roducts_id=298

#7

Supreme Member

iTrader: (1)

Join Date: Sep 2008

Location: Western WA

Posts: 1,347

Likes: 0

Received 1 Like

on

1 Post

Car: 85 Camaro

Engine: No

Transmission: No

Axle/Gears: No

Re: torque arm problem

I guess I didn't say what I meant very well, but yeah I know that. Isn't he talking about the torque arm mount, not the trans mount?

I guess it wouldn't make any sense for them to be talking about helicoils and taps if the problem was the TA mount though...

I guess it wouldn't make any sense for them to be talking about helicoils and taps if the problem was the TA mount though...

Trending Topics

#8

Re: torque arm problem

If you mean the tranny mount, just drill oversize and tap it. Very common to see stripped threads there. If you're talking about the 3 long bolts for the torque arm mount itself, they are through bolts with nuts, there is no thread in the 3 bosses on the tailshaft.

#9

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

Ok the mount on the trans that the torque arm bushing sits in. Its bolted to the tranny fine. But the clamp that goes around the bushing and bolts to the tranny on the top of the mount is what im talking about. Its raining like hell so i cant get under and check it out. 91interceptor if u could take a look i would appreciate it so i know what i need to do when it stops raining.

But if there is supposed to be a long nut with a bolt i will get one and put it in tomorrow in the rain. But there was a shorter bolt that screwed in and got a little tight and seems to be holding for now, it was still in the bracket thats why i asked. But just let me know

But if there is supposed to be a long nut with a bolt i will get one and put it in tomorrow in the rain. But there was a shorter bolt that screwed in and got a little tight and seems to be holding for now, it was still in the bracket thats why i asked. But just let me know

#10

Supreme Member

iTrader: (14)

Join Date: Aug 2006

Location: Central NJ

Posts: 12,650

Likes: 0

Received 44 Likes

on

42 Posts

Car: 86 Trans Am, 92 Firebird

Engine: 408 sbc, 3.1L of raw power

Transmission: TKO600, T5

Axle/Gears: Moser 9", 3:70 trutac, 3:23 torsion

Re: torque arm problem

ok, the torque arm clambshell is held on with nuts and bolts.

#11

Re: torque arm problem

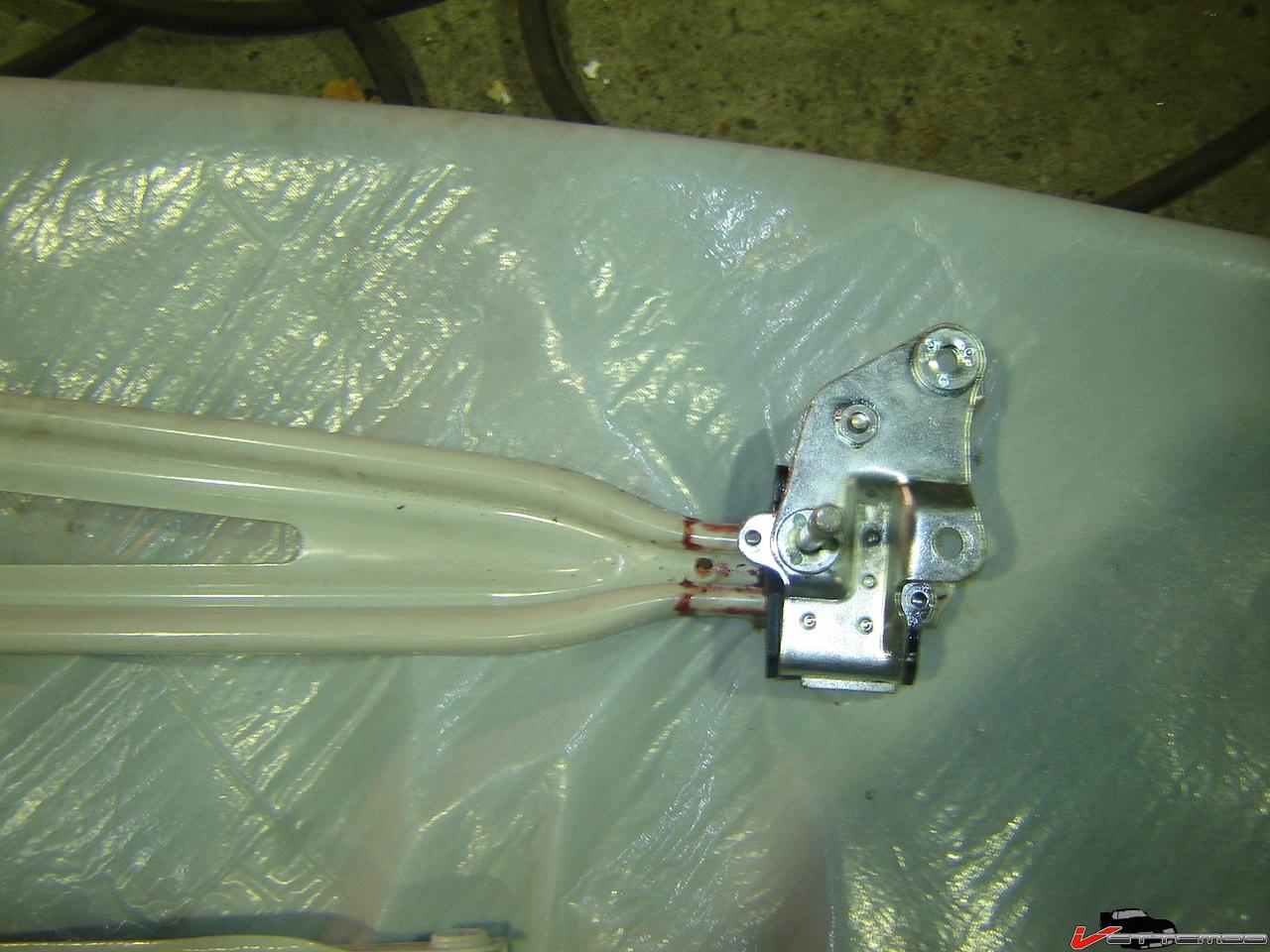

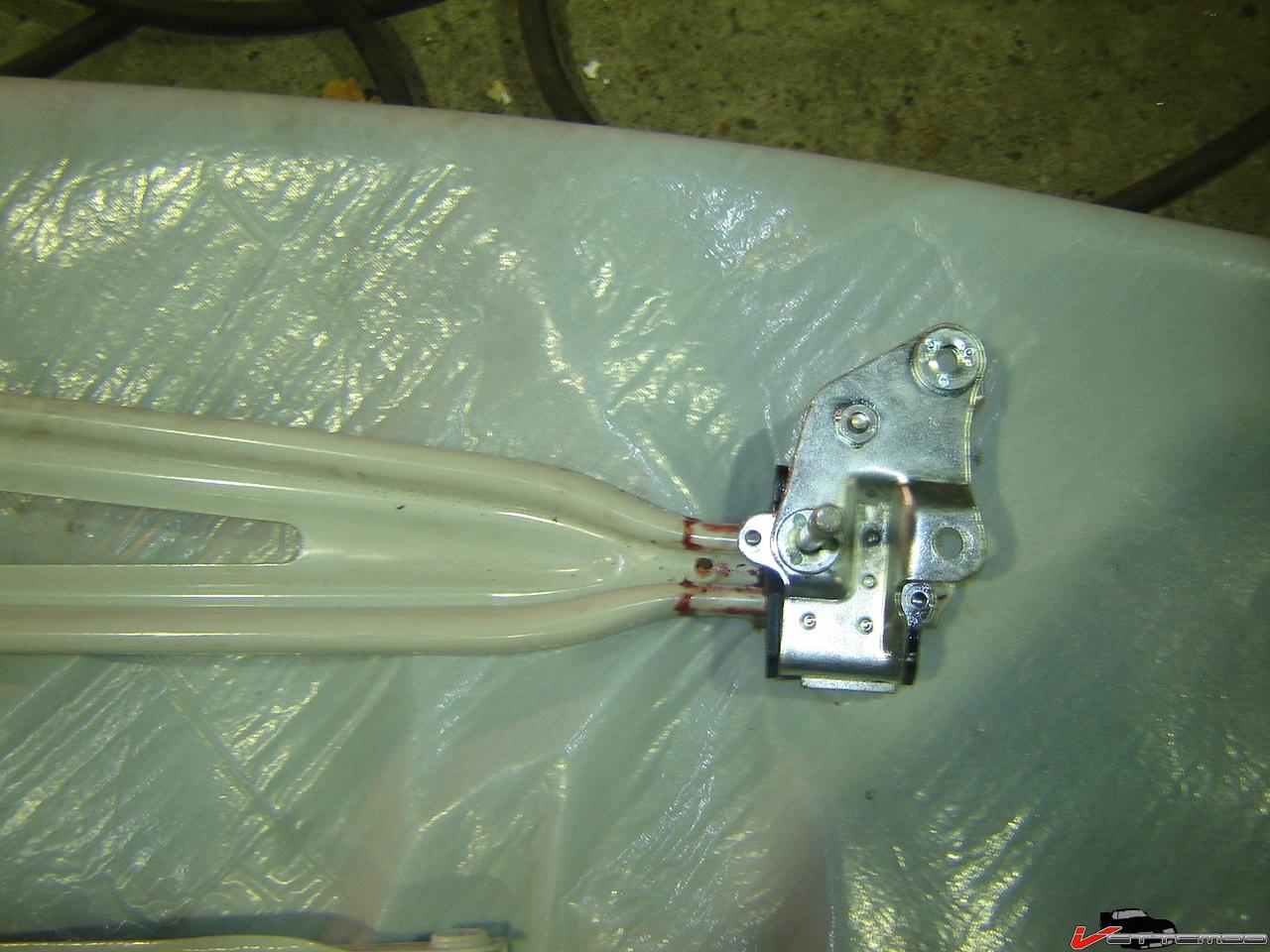

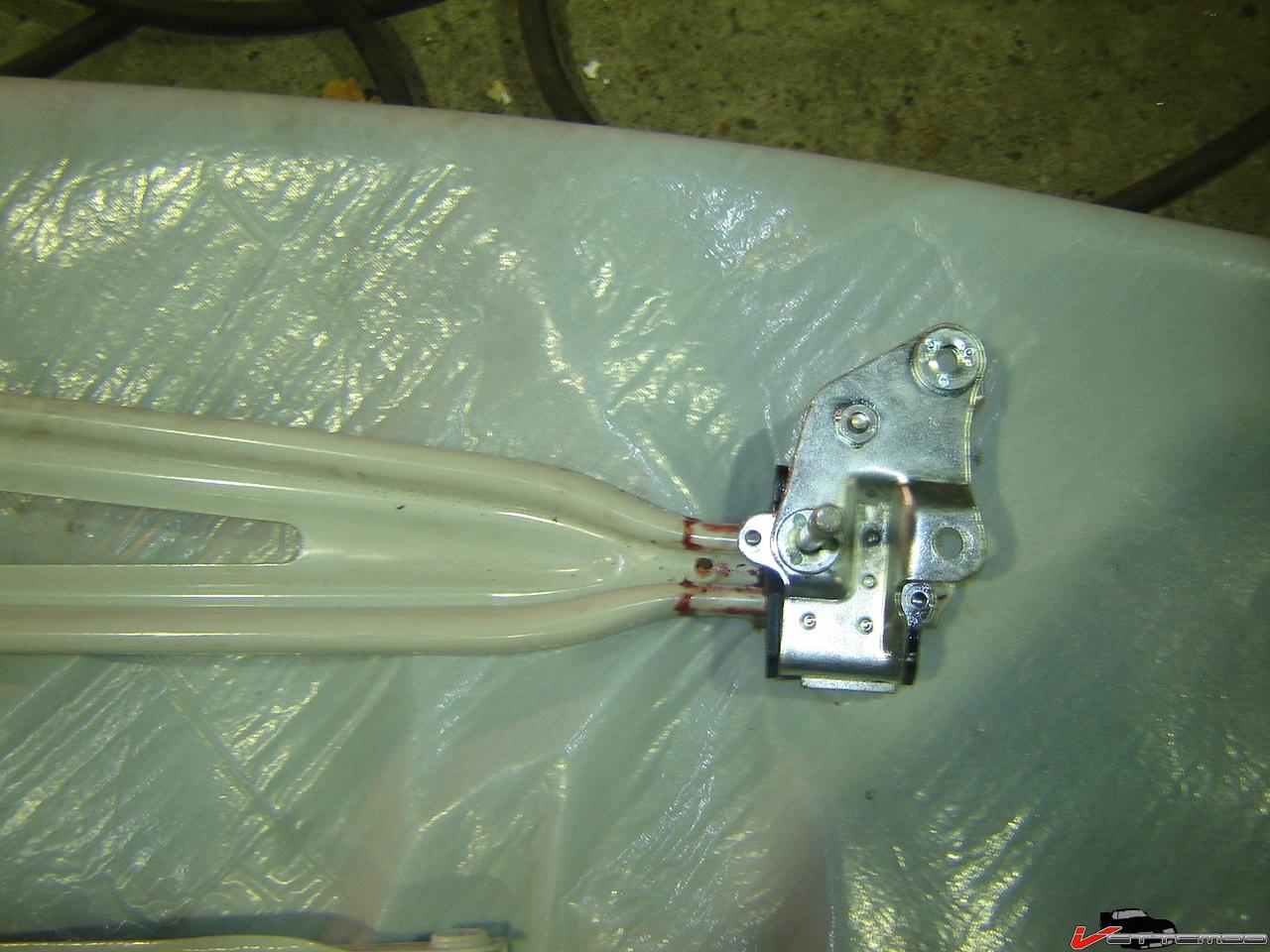

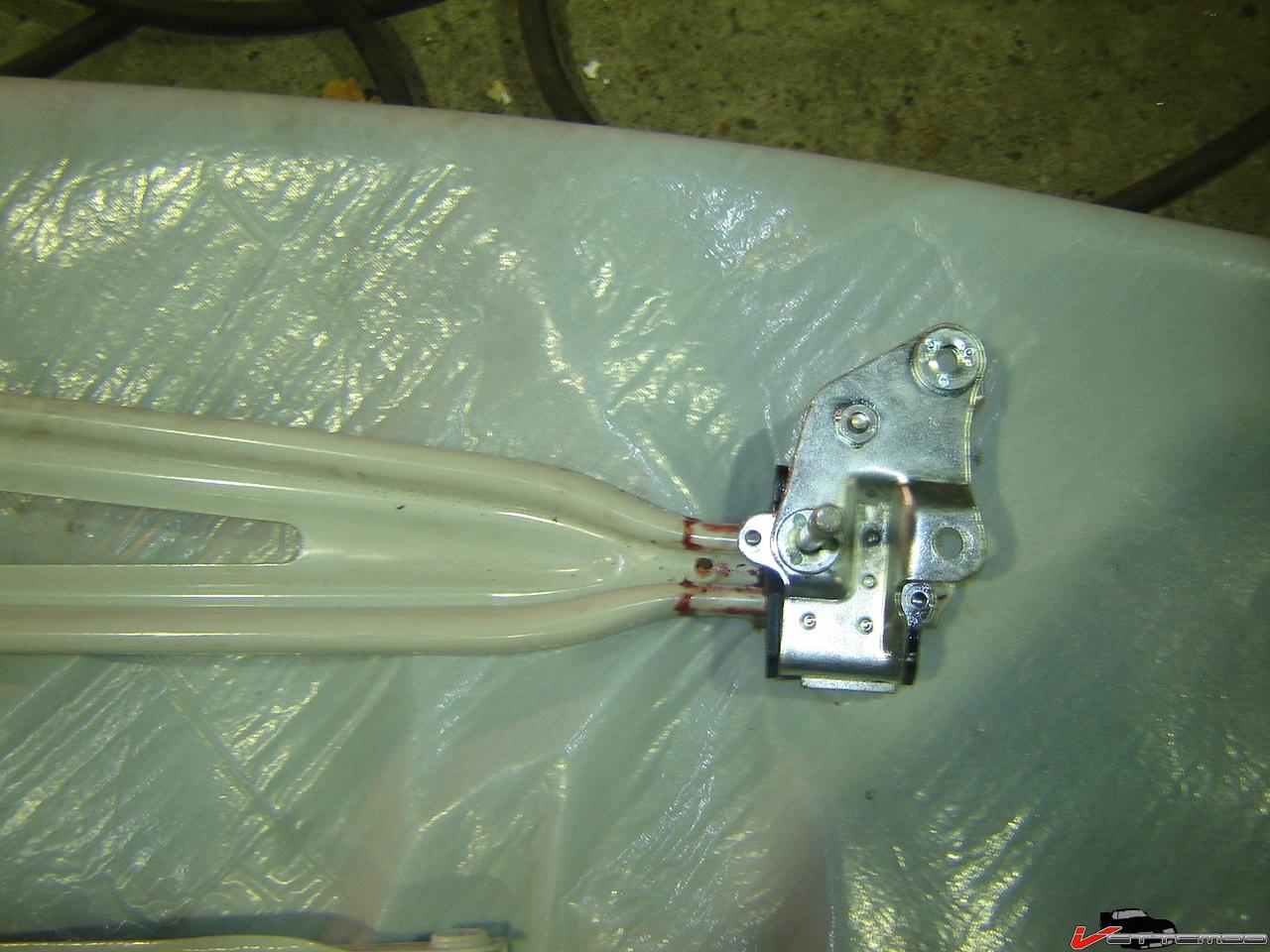

I think he means the 2 part clamp that the bushing itself is clamped in. It has a lip that falls into the parts that bolts to the tranny and has a small bolt up top that tightens it down, this goes into a welded on nut plate on the back of the other part.

This is the part as seen from the tranny side, this face bolts against the tailshaft. You can see the weld nut for the bolt

This is the part as seen from the tranny side, this face bolts against the tailshaft. You can see the weld nut for the bolt

#12

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

I think he means the 2 part clamp that the bushing itself is clamped in. It has a lip that falls into the parts that bolts to the tranny and has a small bolt up top that tightens it down, this goes into a welded on nut plate on the back of the other part.

This is the part as seen from the tranny side, this face bolts against the tailshaft. You can see the weld nut for the bolt

This is the part as seen from the tranny side, this face bolts against the tailshaft. You can see the weld nut for the bolt

#13

Re: torque arm problem

You'll have to lower the trans tailshaft (remove crossmember) to lower it so you can pull the 3 bolts off (if your exh is stock it hangs off this thing also) and remove it so you can work on it. Either grind off the nut and weld a new one on or drill and tap for a larger size. You could also try and use a slightly longer bolt and a nut on the back, you might be able to get that done without pulling it apart.

#14

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

You'll have to lower the trans tailshaft (remove crossmember) to lower it so you can pull the 3 bolts off (if your exh is stock it hangs off this thing also) and remove it so you can work on it. Either grind off the nut and weld a new one on or drill and tap for a larger size. You could also try and use a slightly longer bolt and a nut on the back, you might be able to get that done without pulling it apart.

That doesnt sound to bad, i could probably take it to my old job and they will either let me use the welder or do it for like $10. Bad part is there closed on sundays lol

#15

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

do i have to remove the torque arm to get that mount off or will i be able to get it around it? Will the transmission go low enough with the driveshaft still in or will i need to get it out to?

#17

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

alright well lets hope the bolt holds up until i can get a day off from work

#18

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

Ok it came loose again today so i got the bracket off, didn't have to drop the trans or remove the torque arm either so it took maybe 10 minutes. But mine doesn't have a nut welded to the back it screws into the trans case and there is no where for it to go through for a nut. So it has threads in the T5 case. I can do one of a few different things, first being a helicoil which would require me to drop the trans which i dont want to do. two other options would be to put the bolt through backwards and weld it to the bracket and just put a nut on the outside or weld a nut on the back like twin turbo said. But that would take away one of the mounting points for the bracket, it just has two other bolts that go all the way through plus it would move the bracket away from the trans at the top a little because of the bolt head. Would that work? would those two bolts be strong enough to hold it?

EDIT: also my bracket is different from yours twin turbo mine only has two bolts on the bottom that go all the way through

EDIT: also my bracket is different from yours twin turbo mine only has two bolts on the bottom that go all the way through

Last edited by Seanmay1; 01-18-2010 at 08:42 PM.

#19

Supreme Member

iTrader: (1)

Join Date: Sep 2008

Location: Western WA

Posts: 1,347

Likes: 0

Received 1 Like

on

1 Post

Car: 85 Camaro

Engine: No

Transmission: No

Axle/Gears: No

Re: torque arm problem

Ok it came loose again today so i got the bracket off, didn't have to drop the trans or remove the torque arm either so it took maybe 10 minutes. But mine doesn't have a nut welded to the back it screws into the trans case and there is no where for it to go through for a nut. So it has threads in the T5 case. I can do one of a few different things, first being a helicoil which would require me to drop the trans which i dont want to do. two other options would be to put the bolt through backwards and weld it to the bracket and just put a nut on the outside or weld a nut on the back like twin turbo said. But that would take away one of the mounting points for the bracket, it just has two other bolts that go all the way through plus it would move the bracket away from the trans at the top a little because of the bolt head. Would that work? would those two bolts be strong enough to hold it?

EDIT: also my bracket is different from yours twin turbo mine only has two bolts on the bottom that go all the way through

EDIT: also my bracket is different from yours twin turbo mine only has two bolts on the bottom that go all the way through

#20

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

uploading now to photobucket, dont have any pics from under the car just of the bracket

#21

Member

Thread Starter

Join Date: Oct 2008

Location: GA

Posts: 186

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 Firbird Formula WS6

Engine: TPI 305

Transmission: T 5

Axle/Gears: 3.45 Posi 9 bolt

Re: torque arm problem

this is the side that the other piece of the clamshell goes into

This is the transmission side

Closer view of transmission side, my finger is on the hole that the i want to weld the bolt to that will make a stud for the clamshell. It has the one bolt made into the bracket, then another bolt that goes all the way through with a nut. But the top one threads into the trans, no way it could go all the way through unlesss they can run a bolt through the output shaft

This is the transmission side

Closer view of transmission side, my finger is on the hole that the i want to weld the bolt to that will make a stud for the clamshell. It has the one bolt made into the bracket, then another bolt that goes all the way through with a nut. But the top one threads into the trans, no way it could go all the way through unlesss they can run a bolt through the output shaft

Last edited by Seanmay1; 01-18-2010 at 11:36 PM.

#22

Re: torque arm problem

I didn't realize you have a T5, the one I posted is for an auto. Yes the T5 bracket is different and the top bolt goes into the tailshaft housing and the housing is threaded. If the thread is stripped you have to tap it oversize or use a nutsert (better than heli coil). You'll have to remove the transmission tailshaft or let the rear hang down low enough to be able to access it. I'm not even sure if you can let it hang that low. If need be you can remove the tail section from the main case with the tranny still in the car but you'll need to drive the rollpin for the shifter detent out from the top. Don't loose the spring and ball. The pin will not come out all the way, it only has to be driven down far enough to clear the shifter rail.

Maybe the easiest way is to get a tap and a small ratcheting box wrench small enough to be used on the square head of a thread tap and use that to tap out the hole 1 size bigger. The aluminum is real soft and may not need drilling. Possibly a metric size may be the best bet for a slightly larger size. With the tap and the ratcheting box end wrench you have a low profile setup that you may be able to wrestle in there with the tranny still in place. Another option is to epoxy in a stud but that's a little bubba for my taste.

Maybe the easiest way is to get a tap and a small ratcheting box wrench small enough to be used on the square head of a thread tap and use that to tap out the hole 1 size bigger. The aluminum is real soft and may not need drilling. Possibly a metric size may be the best bet for a slightly larger size. With the tap and the ratcheting box end wrench you have a low profile setup that you may be able to wrestle in there with the tranny still in place. Another option is to epoxy in a stud but that's a little bubba for my taste.

#24

Junior Member

Join Date: Apr 2006

Location: Wilmington, DE

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1984 Camaro/1998 Integra GSR

Engine: 350zz4/GSR SC

Transmission: T-5

Axle/Gears: 10 bolt-4.10 posi

Re: torque arm problem

I had the same problem with my t5, I drilled it out, tapped it bigger and has been fine for over 2k miles. I did drop the trans tho, just the gear box not the bell housing and all.

#25

Re: torque arm problem

Here is the easiest solution. We offer a torque arm relocation crossmember that will eliminate your problem plus save the tailshaft from breaking. This crossmember will also allow you to raise or lower the front of the torque which will effect your cars launching characteristics. If you have any questions please let me know.

http://www.bmrfabrication.com/F3-chassis.htm

http://www.bmrfabrication.com/F3-chassis.htm

#26

Senior Member

iTrader: (15)

Join Date: Jan 2009

Location: Ogden UT

Posts: 753

Likes: 0

Received 0 Likes

on

0 Posts

Car: '88 Camaro (Gone...)

Re: torque arm problem

You should be able to get the tailshaft low enough to access if you remove the 4 bolts holding up the crossmember, the only thing holding it up then will be the motor mounts and the rubber will flex enough to let the rear of the tranny drop. If you go the helicoil route or drill and tap that is

Thread

Thread Starter

Forum

Replies

Last Post

ambainb

Camaros for Sale

11

04-25-2016 09:21 PM

Thirdgen89GTA

NW Indiana and South Chicago Suburb

0

08-20-2015 03:11 PM