Combustion chamber welding

#1

Member

Thread Starter

Combustion chamber welding

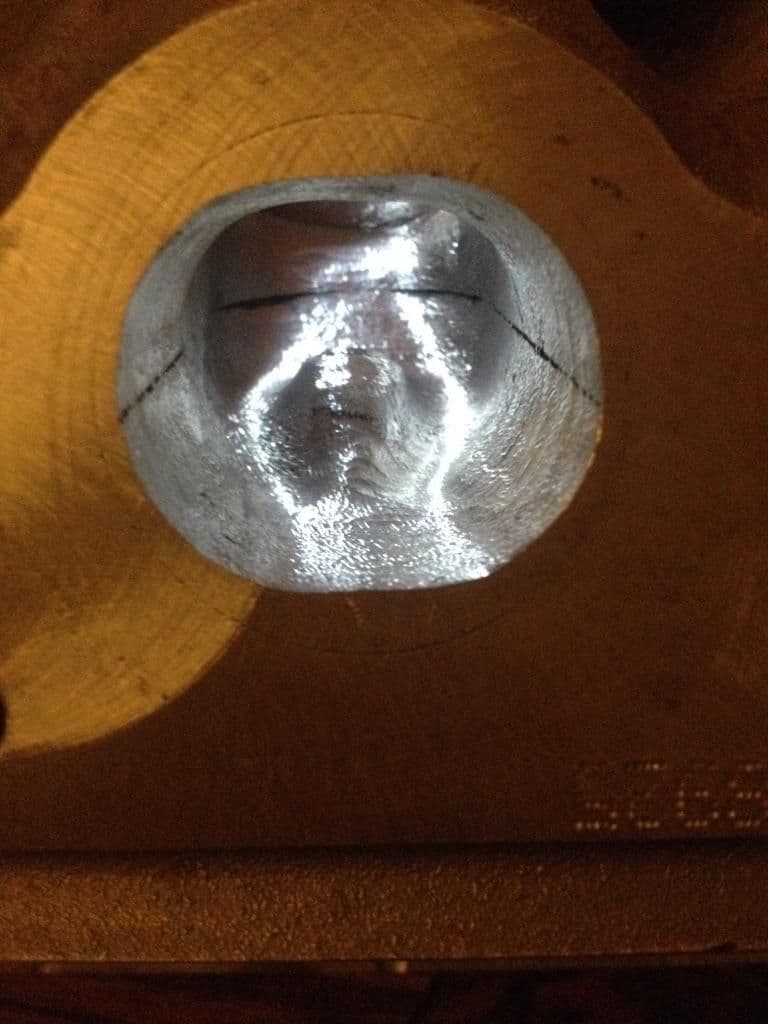

I have a set of 862 5.3 heads for my LS1 that's going in my 84 z28, I'm using the stock flat tops and have having the chambers welded to get them down to 48-50cc depending on if I decide 13.5:1 or 14:1, my question is to you guys, how much weld is it going to take to drop down from 62 and is there enough room to do that without shrouding the intake valve. Be cool to see pics too if any of you guys have had yours done, be nice to see the finished product. Thanks.

Last edited by fbodyfreakls1; 03-05-2017 at 08:04 PM. Reason: Spelling

#2

Moderator

Join Date: Jul 1999

Location: 51°N 114°W, 3500'

Posts: 17,110

Likes: 0

Received 120 Likes

on

101 Posts

Car: 87 IROC L98

Engine: 588 Alcohol BBC

Transmission: Powerglide

Axle/Gears: Ford 9"/31 spline spool/4.86

Re: Combustion chamber welding

Smaller combustion chambers will always shroud the valves plus those heads already have too small a valve for a big engine. If you need that much compression ratio, do it with a dome piston designed for those heads. If a dome piston raises the compression too much, you can increase the size of the chamber to drop it down.

If you really want to change the size of the combustion chamber, you'll need to measure it with a proper cc test. You can always use some spot putty to simulate weld to decrease the size of the chamber.

Welding cast iron however isn't a simple matter of grabbing a welder and running a bead. To get proper penetration, cast iron welding rod should be used plus the metal being welded should be heated up with a torch first. After all that heating and welding, the heads will probably need to be milled to make sure the deck surface is flat and square again which will decrease your chamber size a little more.

If you really want to change the size of the combustion chamber, you'll need to measure it with a proper cc test. You can always use some spot putty to simulate weld to decrease the size of the chamber.

Welding cast iron however isn't a simple matter of grabbing a welder and running a bead. To get proper penetration, cast iron welding rod should be used plus the metal being welded should be heated up with a torch first. After all that heating and welding, the heads will probably need to be milled to make sure the deck surface is flat and square again which will decrease your chamber size a little more.

#3

Supreme Member

Re: Combustion chamber welding

thats the best advice above. ^^^^

I have welded combustion chambers a few times over the years. mostly on motorcycles. if your going to do this, plan on "cc ing" the heads, and use a carbide cutter on a die grinder to shape the chambers and get them all the same volume. definetly TIG them. its a much cleaner weld with better penetration. then smooth them out as you dont want any protruding, sharp spots to cause pre-ignition.

it can be done. is it the best way? all depends on your budget, time, experience, tools, etc.

I have welded combustion chambers a few times over the years. mostly on motorcycles. if your going to do this, plan on "cc ing" the heads, and use a carbide cutter on a die grinder to shape the chambers and get them all the same volume. definetly TIG them. its a much cleaner weld with better penetration. then smooth them out as you dont want any protruding, sharp spots to cause pre-ignition.

it can be done. is it the best way? all depends on your budget, time, experience, tools, etc.

#4

Re: Combustion chamber welding

yep, welding cast iron is a lot more of a challenge than steel. It has to be heated up to between 500-1200 degrees, welded with a cast iron welding rod, and then insulate the head in welding blankets or a bucket of sand so it can cool down slowly to avoid cracking. I do it fairly often at work with the cast iron machines I repair except I use a stick welder instead of a tig which would probably be a better choice.

Last edited by TylerSteez; 03-05-2017 at 09:36 AM. Reason: mistake in temps

#5

Member

Thread Starter

Re: Combustion chamber welding

I should have stated that these are cast aluminum heads off a 5.3 and that they are going to be professionally welded and then I will finish them with a carbide burr and CC them to size. I'm trying to maximize my compression to get the most power I can on the 346 CI I'm working with and the e85 will be a lot cheaper to run than race gas. 13.5:1 or 14:1 will I guess end up being determined by how many cc the chambers are when I'm happy with how they look. I'm putting 2in LS1 valves in the intake side, a step up from the 1.89 I believe the stock 862 valve was. They should support my power goals, I hope anyways and if not I'll call Tony mamo and have him build me a set down the road. Just want the car to run tens on motor and then whatever happens on spray I'll be happy with. I guess I could use a cutter to unshroud the intake valve before I finished the rest of the chamber to try and keep flow impact to a minimum. I'm more worried about good efficient combustion and that's why I'm doing the chambers instead of a domed piston. This is the first set of heads I've done so I'm kinda testing my self to see how they turn out. Hopefully they flow good and work the way I'm hoping. I've ported a few tpi intakes and 302 ho intakes so we will see how this turns out in the end. I'll post up some pics of the heads they are not finished as of yet. Thanks for the comments guys.

Trending Topics

#10

Member

Thread Starter

Re: Combustion chamber welding

Smaller combustion chambers will always shroud the valves plus those heads already have too small a valve for a big engine. If you need that much compression ratio, do it with a dome piston designed for those heads. If a dome piston raises the compression too much, you can increase the size of the chamber to drop it down.

If you really want to change the size of the combustion chamber, you'll need to measure it with a proper cc test. You can always use some spot putty to simulate weld to decrease the size of the chamber.

https://www.youtube.com/watch?v=V7V40ZWNgCo

Welding cast iron however isn't a simple matter of grabbing a welder and running a bead. To get proper penetration, cast iron welding rod should be used plus the metal being welded should be heated up with a torch first. After all that heating and welding, the heads will probably need to be milled to make sure the deck surface is flat and square again which will decrease your chamber size a little more.

If you really want to change the size of the combustion chamber, you'll need to measure it with a proper cc test. You can always use some spot putty to simulate weld to decrease the size of the chamber.

https://www.youtube.com/watch?v=V7V40ZWNgCo

Welding cast iron however isn't a simple matter of grabbing a welder and running a bead. To get proper penetration, cast iron welding rod should be used plus the metal being welded should be heated up with a torch first. After all that heating and welding, the heads will probably need to be milled to make sure the deck surface is flat and square again which will decrease your chamber size a little more.

Clay/putty is an amazing idea, thank you for that. I can't believe I didn't think of it lol I need to get a cc kit and the LS1 valves installed so I can finish my ports. Then I can clay/putty my chambers and mock them up to what they need to look like, take some pictures and give them to my guy who's welding my heads to give him a rough idea of what they need to look like. Help him not weld too much or little. Thanks again for the ideas and advice and the video!!