cheap N2O setup

#1

Member

Thread Starter

Join Date: Jan 2004

Location: Augusta Georgia

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 95 350 LT1

Transmission: 4L60E

cheap N2O setup

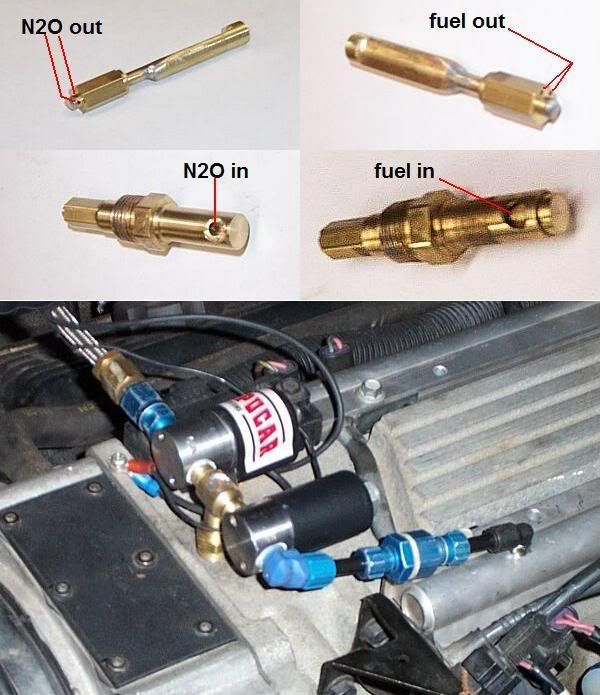

Those who know me here know I have time but no money. I had a fuel solenoid, the N2O hose and a bottle left over from an old NOS plate system, I also had a new Compucar N2O solenoid that I got from Ernie Wrenn. Ernie owned Compucar up until recently, he gave me the solenoid to use in an experimental fuel fuel setup for one of my gas turbines. Ernie is hooked on turbines big time, he should be showing up at the drag strip with a jet car next season. I had some free time so I made my own N2O nozzle and added it to the other parts I had and put it on my LT1.

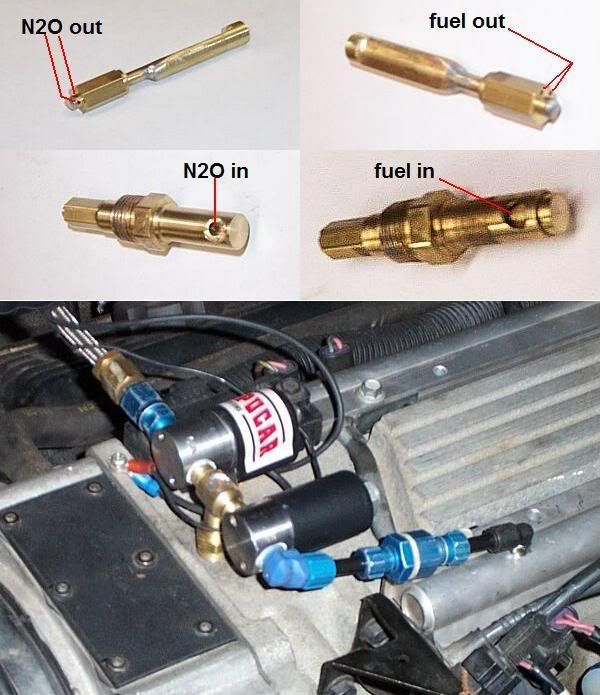

The nozzle should support about 200 horsepower. Inside the cross piece that the solenoids screw on to is where the jets go. I made the jets myself too. The fuel goes in and past the outside of the center core and out 2 holes that point down. The N2O goes in through the center core and exits through 2 holes drilled in the side of the little nub on the end. The N2O holes are in line with the fuel holes, when the N2O comes out it just shreds the hell out of the fuel stream. I found a jet calculator on line, I had the correct drill bits to make a set of 95 horsepower jets, .045 N2O and .025 gas.

My son and I just tested it, it seems to work pretty good, we hit the button in first gear at about 3500 and held it until we got up to about 100 mph. It definitly pulled a hell of a lot harder. I had datamaster going and as soon as I hit the button I could see the PCM pull about 10 degrees out. This is with regular gas and that's a little more than what it pulls out normally, it crept back until it only had about 7 degrees pulled out but it counted a few knocks so it popped back to about 10 degrees and hovered between 7 and 10 for the whole run.

Both O2 sensors stayed rich so I guess I didn't go lean. I'll have to put some good gas in it and try it at the dragstrip. I have an ON delay I'll use with a WOT throttle switch. A little delay and it will come on right around 3000 rpm after i leave. I'm planning on a window switch in the near future and maybe a low fuel pressure cutoff switch. If it works ok then I'll make some 150 hp jets, and when I get enough money to break stuff I'll probably make a set of 175 or 200 hp jets.

I can remove the whole setup and change jets or whatever in just a few minutes. I made a little fuel filter that can be seen in the line between the fuel solenoid and the fuel rail. Don't let those little plastic hoses fool you, I've burst tested them at 200 psi, they're used in the lasers I work on and they last for years in some pretty harsh enviorments.

I still have that huge plastic intake sound damper aka first base that was stock on the roadmasters and impalas with the LT1. I guess I'll put that back on to hide the whole setup.

The nozzle should support about 200 horsepower. Inside the cross piece that the solenoids screw on to is where the jets go. I made the jets myself too. The fuel goes in and past the outside of the center core and out 2 holes that point down. The N2O goes in through the center core and exits through 2 holes drilled in the side of the little nub on the end. The N2O holes are in line with the fuel holes, when the N2O comes out it just shreds the hell out of the fuel stream. I found a jet calculator on line, I had the correct drill bits to make a set of 95 horsepower jets, .045 N2O and .025 gas.

My son and I just tested it, it seems to work pretty good, we hit the button in first gear at about 3500 and held it until we got up to about 100 mph. It definitly pulled a hell of a lot harder. I had datamaster going and as soon as I hit the button I could see the PCM pull about 10 degrees out. This is with regular gas and that's a little more than what it pulls out normally, it crept back until it only had about 7 degrees pulled out but it counted a few knocks so it popped back to about 10 degrees and hovered between 7 and 10 for the whole run.

Both O2 sensors stayed rich so I guess I didn't go lean. I'll have to put some good gas in it and try it at the dragstrip. I have an ON delay I'll use with a WOT throttle switch. A little delay and it will come on right around 3000 rpm after i leave. I'm planning on a window switch in the near future and maybe a low fuel pressure cutoff switch. If it works ok then I'll make some 150 hp jets, and when I get enough money to break stuff I'll probably make a set of 175 or 200 hp jets.

I can remove the whole setup and change jets or whatever in just a few minutes. I made a little fuel filter that can be seen in the line between the fuel solenoid and the fuel rail. Don't let those little plastic hoses fool you, I've burst tested them at 200 psi, they're used in the lasers I work on and they last for years in some pretty harsh enviorments.

I still have that huge plastic intake sound damper aka first base that was stock on the roadmasters and impalas with the LT1. I guess I'll put that back on to hide the whole setup.

Last edited by SERPENT99; 10-23-2005 at 09:30 PM.

#2

Supreme Member

iTrader: (2)

Join Date: Jan 2001

Location: Tampa, FL, USA

Posts: 4,149

Likes: 0

Received 2 Likes

on

2 Posts

Car: 93 240SX

Engine: LQ9

Transmission: T56

Axle/Gears: 3.54 R200 IRS

Very interesting stuff, but i'd be concerned about the location of your nozzle, i'm quite sure people havent had the best time with distribution on LT1 plate setups sandwiched between the intake manifold and throttle body, so with how much more rearward that nozzle is mounted in the intake its probably hitting a lot harder on the rear cylinders than the front. I'd really consider moving it pre TB if I were you...

#3

Member

Thread Starter

Join Date: Jan 2004

Location: Augusta Georgia

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 95 350 LT1

Transmission: 4L60E

unless you go direct port injection there will never be perfect distribution. The nozzle I made has 2 N2O ports with a 60 degree spread, I tried a few different spread angles and different size holes, what I ended up with gives a wide soft low velocty plume. Nothing shoots N2O to the back of the manifold.

About going before the TB- All the information I've read says it's best to have the nozzles as close to the cylinders as possible. Having the nozzles before the TB can cause a horsepower loss as the TB will have to flow air/N2O/gas as opposed to just flowing air. It will flow less air to compensate for the N2O and gas it has to flow.

If you know about using N2O why don't you help me out and give me some info about how much spark retard I should see. What are your experiences with sprayed LT1's?

About going before the TB- All the information I've read says it's best to have the nozzles as close to the cylinders as possible. Having the nozzles before the TB can cause a horsepower loss as the TB will have to flow air/N2O/gas as opposed to just flowing air. It will flow less air to compensate for the N2O and gas it has to flow.

If you know about using N2O why don't you help me out and give me some info about how much spark retard I should see. What are your experiences with sprayed LT1's?

#4

Supreme Member

iTrader: (2)

Join Date: Jan 2001

Location: Tampa, FL, USA

Posts: 4,149

Likes: 0

Received 2 Likes

on

2 Posts

Car: 93 240SX

Engine: LQ9

Transmission: T56

Axle/Gears: 3.54 R200 IRS

The first thing actually wrong is the jet sizes you list,

You state you are using .045N/.025F for a "95HP" shot...

Heres NX's suggested Jetting for a 100 - 52N/33F

And another, more accurate, and closer to a final tune- 47N/27F

The second being for a 1000 lb bottle pressure.

NX's 75 HP 41N/24F, and the other the same, so your fuel side is a hair more than the typical 75 shot, and real close to the 100 shot on the fuel side, so you are quite possibly lean even if your sensors are saying you are rich, or you are running higher fuel pressure. It also doesnt seem you are running a nitrous pressure gauge, or anything to stabilize bottle pressure, so some info there would help.

Typical suggestions are normally 2* per 50 HP, and typically people with basic kits like yours on LT1's arent normally purposely pulling timing, just letting the computer pull the little that it may, i'd definetly look into why you are pulling so much, try a larger fuel jet and see what happens.

You state you are using .045N/.025F for a "95HP" shot...

Heres NX's suggested Jetting for a 100 - 52N/33F

And another, more accurate, and closer to a final tune- 47N/27F

The second being for a 1000 lb bottle pressure.

NX's 75 HP 41N/24F, and the other the same, so your fuel side is a hair more than the typical 75 shot, and real close to the 100 shot on the fuel side, so you are quite possibly lean even if your sensors are saying you are rich, or you are running higher fuel pressure. It also doesnt seem you are running a nitrous pressure gauge, or anything to stabilize bottle pressure, so some info there would help.

Typical suggestions are normally 2* per 50 HP, and typically people with basic kits like yours on LT1's arent normally purposely pulling timing, just letting the computer pull the little that it may, i'd definetly look into why you are pulling so much, try a larger fuel jet and see what happens.

#5

Senior Member

Join Date: Dec 2003

Location: Newberry, Mi

Posts: 539

Likes: 0

Received 0 Likes

on

0 Posts

Car: transam, el camino

Engine: 415

Transmission: T56

Pretty neat.  are you running a seperate a/f guage or how did you know what the stock sensors were reading? -Ben

are you running a seperate a/f guage or how did you know what the stock sensors were reading? -Ben

are you running a seperate a/f guage or how did you know what the stock sensors were reading? -Ben

are you running a seperate a/f guage or how did you know what the stock sensors were reading? -Ben

#6

Member

Thread Starter

Join Date: Jan 2004

Location: Augusta Georgia

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 95 350 LT1

Transmission: 4L60E

i ran datamaster in the record mode.

heh heh I used to have a 69 malibu with dana 4x4 axles in it along with a TH400, dana transfer case and a 454. We called it the CHEVELLE FROM HELL

heh heh I used to have a 69 malibu with dana 4x4 axles in it along with a TH400, dana transfer case and a 454. We called it the CHEVELLE FROM HELL

#7

Originally posted by SERPENT99

unless you go direct port injection there will never be perfect distribution. The nozzle I made has 2 N2O ports with a 60 degree spread, I tried a few different spread angles and different size holes, what I ended up with gives a wide soft low velocty plume. Nothing shoots N2O to the back of the manifold.

unless you go direct port injection there will never be perfect distribution. The nozzle I made has 2 N2O ports with a 60 degree spread, I tried a few different spread angles and different size holes, what I ended up with gives a wide soft low velocty plume. Nothing shoots N2O to the back of the manifold.

Pretty cool otherwise, though Iíd bet that youíve got close to the time and $ of a cheap fogger nozzle in it now.

Iím curious, what size are the outlets drilled? What did that pile of brass start as? I see what appear to be a couple of recognizable fittings but Iím not sure that I recognize much else besides the solder (I need to build a fogger/mister nozzle of sorts for something totally different and really donít want to spend money on the ďrightĒ parts)

About going before the TB- All the information I've read says it's best to have the nozzles as close to the cylinders as possible. Having the nozzles before the TB can cause a horsepower loss as the TB will have to flow air/N2O/gas as opposed to just flowing air. It will flow less air to compensate for the N2O and gas it has to flow.

I think that your setup might be very slick mounted right in front of the TB, on my LT1 car I actually modified the MAF to mount the nossle in the back of the maf and I loved the way it workedÖ

If you know about using N2O why don't you help me out and give me some info about how much spark retard I should see. What are your experiences with sprayed LT1's?

As far as retard by the ECM, that would imply that the ecm is picking something up that it sees as pinging (the cooling of the intake, if anything will result in more timing), so I think you have a problem. I donít remember seeing any abnormal pinging/retard on my LT1 at least no different then NA (nothing besides the normal bit on the shifts).

Trending Topics

#8

Originally posted by Z28*****

The first thing actually wrong is the jet sizes you list,

You state you are using .045N/.025F for a "95HP" shot...

Heres NX's suggested Jetting for a 100 - 52N/33F

And another, more accurate, and closer to a final tune- 47N/27F

The second being for a 1000 lb bottle pressure.

NX's 75 HP 41N/24F, and the other the same, so your fuel side is a hair more than the typical 75 shot, and real close to the 100 shot on the fuel side, so you are quite possibly lean even if your sensors are saying you are rich, or you are running higher fuel pressure. It also doesnt seem you are running a nitrous pressure gauge, or anything to stabilize bottle pressure, so some info there would help.

The first thing actually wrong is the jet sizes you list,

You state you are using .045N/.025F for a "95HP" shot...

Heres NX's suggested Jetting for a 100 - 52N/33F

And another, more accurate, and closer to a final tune- 47N/27F

The second being for a 1000 lb bottle pressure.

NX's 75 HP 41N/24F, and the other the same, so your fuel side is a hair more than the typical 75 shot, and real close to the 100 shot on the fuel side, so you are quite possibly lean even if your sensors are saying you are rich, or you are running higher fuel pressure. It also doesnt seem you are running a nitrous pressure gauge, or anything to stabilize bottle pressure, so some info there would help.

They are also usually moved around some by the manufacturorís recommended bottle pressure (NX seems to try to keep bottle pressure about 100psi higher then the rest), nossle opening sizes/flow and solenoid restriction/flow.

I really wouldnít worry about it, seems like youíve got starting numbers to work off of and then tune from there, who cares who recommends what. That and honestly I donít know that I believe your hand drilled jets are accurate enough to quibble over a couple of sizes one way over the other.

#10

Member

Thread Starter

Join Date: Jan 2004

Location: Augusta Georgia

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

Car: 89 IROC

Engine: 95 350 LT1

Transmission: 4L60E

thanks for the input Crossfire. You have a good point, they do go rich with most N2O setups. About the jets, they are kind of tricky to get good flow control with. The hole size is one thing, the entrance and exit to the hole and the thickness of the material that the metering hole was drilled in are important. I keep all these dimensions the same and vary just the metering orifice size. I flow tested some of my fuel jets and I was suprised to see my results were very close to what my jet chart predicted. I haven't figured out a practical way to flow test the N2O jets. I could turn the system on and monitor the bottle weight loss but unlike the fuel, I can't just spray the N2O into a bucket and pour it back into the bottle for another test. It would get kind of expensive and the bottle pressure would also have to be controlled. I'll stay a little on the rich side and get my hands on a wideband O2 when I get a chance. I'd like to see the A/F ratio on all the individual cylinders if I could.

The actual outlet holes are .045, 2 for the gas, 2 for the N2O. The brass body was a hose barb and some solid brass hex stock I had laying around made the rest. The N2O outlets practticaly point right at the front intake runners but the plume is pretty full and it fans out really nicely. I should have taken some pictures when i tested it.

I thought about a fogger nozzle but I wanted something that would support about 200 horsepower and I really wanted to tailor the spray pattern/distribution,... and I had nothing to do. I have $0 in the whole setup so far.

rocluvr, cheap and N2O is ok, don't be scared. What's important is taking the time to figure it all out. it's the hasty hack jobs that scare me, and some hack jobs have money thrown in but it doesn't help. Thanks for the complements.

The actual outlet holes are .045, 2 for the gas, 2 for the N2O. The brass body was a hose barb and some solid brass hex stock I had laying around made the rest. The N2O outlets practticaly point right at the front intake runners but the plume is pretty full and it fans out really nicely. I should have taken some pictures when i tested it.

I thought about a fogger nozzle but I wanted something that would support about 200 horsepower and I really wanted to tailor the spray pattern/distribution,... and I had nothing to do. I have $0 in the whole setup so far.

rocluvr, cheap and N2O is ok, don't be scared. What's important is taking the time to figure it all out. it's the hasty hack jobs that scare me, and some hack jobs have money thrown in but it doesn't help. Thanks for the complements.

Thread

Thread Starter

Forum

Replies

Last Post